Stainless steel plate and sheet 304/304L,201,202,310S,316L,316Ti,410,420,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

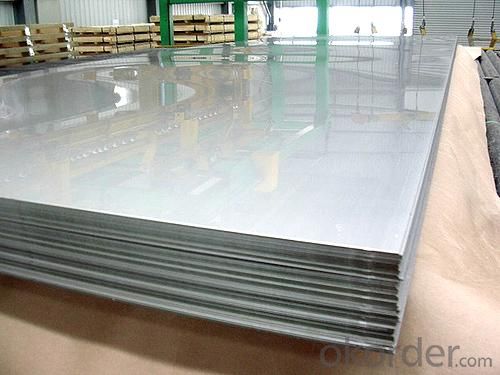

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

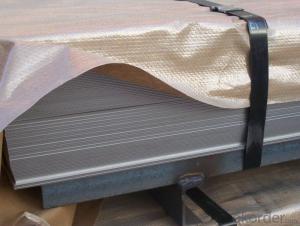

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: How do you calculate the cost of a stainless steel sheet?

- To calculate the cost of a stainless steel sheet, you would typically consider factors such as the dimensions, thickness, grade of stainless steel, and market prices. By multiplying the area of the sheet with the cost per square unit, you can determine the total cost. It is important to consider additional expenses like shipping, handling, and any applicable taxes or fees.

- Q: How do you remove oil stains from stainless steel sheets?

- To remove oil stains from stainless steel sheets, you can start by wiping the surface with a clean, soft cloth dampened with warm water and mild dish soap. If the stain persists, apply a small amount of vinegar or rubbing alcohol onto the cloth and gently rub the affected area. Rinse with water and dry thoroughly to avoid water spots.

- Q: What are stainless steel sheets used for?

- Stainless steel sheets serve a multitude of purposes in diverse industries. Their outstanding resistance to corrosion, durability, and attractive appearance make them highly sought after in both commercial and residential settings. Within the construction field, these sheets are utilized for roofing, cladding, and facades due to their ability to withstand harsh environmental conditions while providing a contemporary and sleek look. In the automotive industry, they are frequently employed in the construction of car bodies, exhaust systems, and decorative trims. Furthermore, stainless steel sheets find extensive use in the food and beverage sector, where their hygienic qualities make them ideal for kitchen equipment, countertops, and food processing machinery. Additionally, they are widely used in medical equipment, pharmaceuticals, and laboratory settings due to their resistance to corrosion and ease of cleaning. They are also employed in furniture, appliances, signage, and for decorative purposes, as they can be easily customized and molded into various shapes and sizes. All in all, stainless steel sheets are an adaptable material that fulfills a diverse array of requirements in different industries, owing to their strength, durability, and corrosion resistance properties.

- Q: How are stainless steel sheets produced?

- Stainless steel sheets are produced through a process called hot rolling, where stainless steel ingots are heated and passed through a series of rollers to reduce their thickness and improve their surface finish. This continuous rolling process creates long sheets of stainless steel, which are then cooled and cut into desired lengths. The sheets may undergo further processing, such as annealing or surface treatment, before being packaged and shipped for various applications.

- Q: Can stainless steel sheets be cut or shaped easily?

- Yes, stainless steel sheets can be cut or shaped easily. Stainless steel is known for its excellent machinability and workability, making it relatively easy to cut, shape, and form into desired shapes or sizes with the right tools and techniques.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, there are several easy steps you can follow: 1. Clean the surface regularly: Wiping the stainless steel sheets with a soft cloth or microfiber cloth on a regular basis can help prevent fingerprints and smudges from building up. 2. Use mild soap and water: Mix a few drops of mild dish soap with warm water, and dip the cloth into this solution. Gently wipe the stainless steel surface, following the grain, to remove any dirt or oil that may attract fingerprints. 3. Dry thoroughly: After cleaning, make sure to dry the stainless steel sheets thoroughly using a clean, dry cloth. This will help prevent water spots or streaks that can make the surface appear smudged. 4. Avoid abrasive cleaners or tools: Harsh chemicals, abrasive cleaners, or scrub brushes can damage the stainless steel finish, making it more prone to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths to maintain the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Using a stainless steel cleaner or polish can create a protective barrier on the surface, making it more resistant to fingerprints and smudges. Follow the instructions on the product and apply it with a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you know that your hands tend to leave fingerprints easily, consider wearing gloves while handling stainless steel sheets. This can help prevent direct contact with the surface and minimize the chances of leaving smudges. By following these tips, you can maintain the cleanliness and shine of your stainless steel sheets, preventing fingerprints and smudges from detracting from their appearance.

- Q: How do you prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, it is important to use lubricants or anti-seize compounds during the manufacturing or assembly process. This helps reduce friction and surface adhesion, minimizing the risk of galling. Additionally, using proper cutting tools and techniques, such as slow speeds and low feed rates, can also help prevent galling.

- Q: Are stainless steel sheets resistant to intergranular corrosion?

- Yes, stainless steel sheets are generally resistant to intergranular corrosion due to the presence of chromium in their alloy composition. Chromium forms a protective oxide layer on the surface of stainless steel, preventing corrosive substances from penetrating the material and causing intergranular corrosion.

- Q: Are stainless steel sheets suitable for railway applications?

- Yes, stainless steel sheets are suitable for railway applications. They offer excellent corrosion resistance, durability, and strength, making them ideal for various components such as train carriages, structural elements, and infrastructure. Additionally, stainless steel's low maintenance requirements and ability to withstand harsh environmental conditions make it a reliable choice for railway applications.

- Q: Can stainless steel sheets be used for food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their excellent corrosion resistance, durability, and ease of cleaning. They do not react with food, making them safe for use in various food processing applications such as food preparation surfaces, equipment, and storage containers.

Send your message to us

Stainless steel plate and sheet 304/304L,201,202,310S,316L,316Ti,410,420,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords