stainless steel pipes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipes

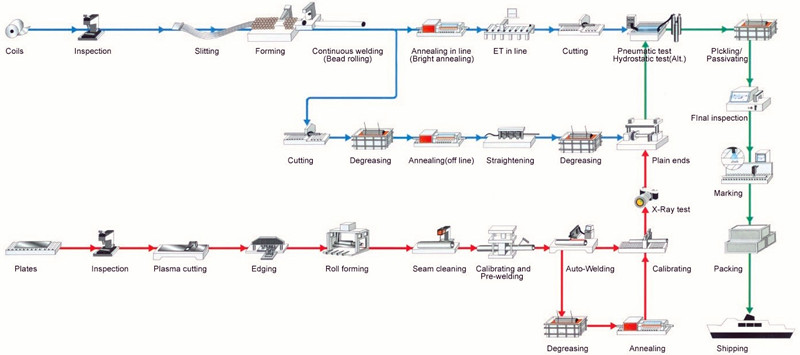

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q: Can stainless steel pipes be used for firefighting systems?

- Firefighting systems can utilize stainless steel pipes due to their durability and resistance to corrosion. The material's ability to withstand heat, pressure, and chemicals makes it suitable for transporting water, foam, and other fire suppression agents. In addition to its high strength and ability to endure extreme conditions, stainless steel pipes are also recognized for their smooth inner surface, which reduces friction loss and maximizes water flow. This quality is crucial for the effectiveness of firefighting operations. Overall, stainless steel pipes offer a dependable and long-lasting solution for firefighting systems, ensuring safety and efficiency in critical situations.

- Q: Can stainless steel pipes be used in the renewable energy industry?

- Yes, stainless steel pipes can be used in the renewable energy industry. Stainless steel is corrosion-resistant, durable, and able to withstand high temperatures and pressures, making it suitable for various applications in renewable energy systems such as solar thermal, geothermal, and biomass. It is commonly used for transporting fluids, gases, and steam in these systems, ensuring reliable and efficient energy production.

- Q: Are stainless steel pipes suitable for liquid storage tanks?

- Indeed, liquid storage tanks can accommodate stainless steel pipes. Stainless steel exhibits remarkable resistance to corrosion, rendering it exceptionally well-suited for housing a multitude of liquids, such as water, chemicals, and foodstuffs. Its exceptional resistance to rust, oxidation, and staining guarantees the preservation of the stored liquids' purity. Moreover, stainless steel pipes possess impressive strength and durability, enabling them to withstand the weight and pressure exerted by the stored liquids. Furthermore, stainless steel's ease of cleaning and maintenance further establishes its dependability for liquid storage purposes.

- Q: What is the maximum wall thickness for stainless steel pipes?

- The maximum wall thickness for stainless steel pipes can vary depending on various factors such as the specific grade of stainless steel, the manufacturing process, and the intended application. However, in general, stainless steel pipes typically have a maximum wall thickness of around 40 millimeters.

- Q: Stainless steel seamless steel tube, ordinary seamless steel pipe, which is good?

- There are many kinds of seamless steel tubes. If you require high strength, the strength of the ordinary seamless tube is higher than that of the stainless steel

- Q: How do you prevent blockages in stainless steel pipes?

- To prevent blockages in stainless steel pipes, there are several measures you can take: 1. Regular cleaning: Clean the pipes on a regular basis to remove any accumulated debris or residue. This can be done using various cleaning methods such as mechanical cleaning tools or chemical cleaning solutions that are safe for stainless steel. 2. Proper disposal of waste: Ensure that you dispose of waste materials properly, avoiding dumping substances that can cause blockages, such as grease, oil, food scraps, or other solids. Use appropriate waste disposal systems or filters to trap these substances before they enter the pipes. 3. Avoid corrosive substances: Stainless steel pipes are resilient to corrosion, but exposure to certain highly corrosive substances can cause damage and blockages. Avoid using or disposing of chemicals or substances that are known to corrode stainless steel pipes. 4. Regular inspections: Conduct regular inspections of the pipes to identify any signs of blockages or potential issues. This can help in detecting problems early on and taking necessary preventive measures. 5. Proper installation: Ensure that the pipes are installed correctly, with proper alignment, support, and connections. This will help prevent the formation of blockages due to misaligned or poorly connected pipes. 6. Use strainers or filters: Install strainers or filters at the entry points of the pipes to catch any large particles or debris that can potentially block the pipes. Regularly clean or replace these strainers to maintain their effectiveness. 7. Avoid high-temperature buildup: Excessive heat can cause substances to solidify or congeal, leading to blockages. Avoid allowing substances to cool and solidify in the pipes by maintaining a suitable temperature and preventing sudden temperature changes. 8. Regular maintenance: Implement a regular maintenance schedule to keep the pipes in optimal condition. This can include activities such as flushing the pipes with hot water or using specialized cleaning solutions to remove any buildup or residue. By following these preventive measures, you can significantly reduce the chances of blockages in stainless steel pipes, ensuring their long-term functionality and minimizing the need for costly repairs or replacements.

- Q: Can stainless steel pipes be wrapped with tape?

- Yes, stainless steel pipes can be wrapped with tape. However, it is important to use the appropriate type of tape designed specifically for stainless steel. This is because stainless steel pipes are often used in industrial and high-temperature applications, and ordinary tapes may not be able to withstand the extreme conditions. Stainless steel pipe tapes are typically made of materials like stainless steel foil or aluminum foil with a heat-resistant adhesive to ensure long-lasting durability and resistance to corrosion. These tapes can be used for various purposes such as insulation, sealing, or protection against abrasion. It is always recommended to consult the manufacturer's guidelines or seek professional advice before applying any tape to stainless steel pipes to ensure proper installation and avoid any potential issues.

- Q: Can stainless steel pipes be used for chemical laboratories?

- Yes, stainless steel pipes can be used for chemical laboratories. Stainless steel is highly resistant to corrosion and can withstand a wide range of chemicals and temperatures, making it an ideal material for handling and transporting various chemicals in a laboratory setting. It offers excellent durability, strength, and reliability, making it suitable for use in both standard and specialized laboratory applications. Additionally, stainless steel pipes are easy to clean and maintain, ensuring a hygienic and safe environment in the laboratory.

- Q: Can stainless steel pipes handle high-velocity fluid flow?

- High-velocity fluid flow can indeed be handled by stainless steel pipes. Renowned for their remarkable strength, durability, and corrosion resistance, stainless steel pipes are well-suited for managing high-velocity fluid flow. They possess the ability to endure the pressure and turbulence created by swiftly moving fluids. Moreover, the smooth inner surfaces of stainless steel pipes reduce friction and aid in sustaining the velocity of the fluid flow. As a consequence, stainless steel pipes find widespread application in industries like oil and gas, chemical processing, and power generation, where encounters with high-velocity fluid flow are frequent.

- Q: How do you calculate the flow rate of stainless steel pipes?

- To calculate the flow rate of stainless steel pipes, you can use the Hazen-Williams equation or the Darcy-Weisbach equation. The Hazen-Williams equation is commonly used for water flow in commercial and industrial applications, while the Darcy-Weisbach equation is more general and can be used for various fluids. For the Hazen-Williams equation, the flow rate (Q) can be calculated using the formula: Q = 0.849 * C * (D^2.63) * (h^0.54) Where: Q = Flow rate in gallons per minute (GPM) C = Hazen-Williams coefficient (an empirical value that depends on the pipe material and condition) D = Inside diameter of the pipe in inches h = Head loss or pressure drop in feet For the Darcy-Weisbach equation, the flow rate (Q) can be calculated using the formula: Q = (π/4) * (D^2) * V Where: Q = Flow rate in cubic meters per second (m³/s) D = Inside diameter of the pipe in meters V = Velocity of the fluid in meters per second (m/s) To determine the velocity (V), you can use the formula: V = Q / ((π/4) * (D^2)) These equations provide a theoretical estimation of the flow rate in stainless steel pipes. However, it is important to note that other factors such as pipe roughness, fluid viscosity, and system pressure can also affect the flow rate. Therefore, it is recommended to consult relevant engineering standards, industry guidelines, or work with a qualified engineer for accurate calculations.

Send your message to us

stainless steel pipes

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords