Splice Routel AJ13

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

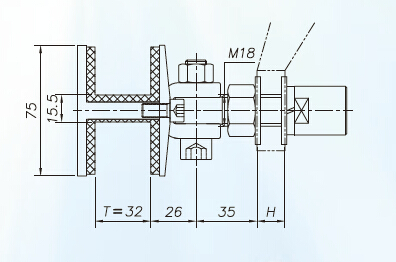

Product Name | Splice Routel AJ13 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 32mm |

Bolt Size | M18 |

Max. axial bearing capacity | 6000N |

Max. Radial Bearing capacity | 2500N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

Splice Routel AJ13

- Q: The installation method of the splicing jaws

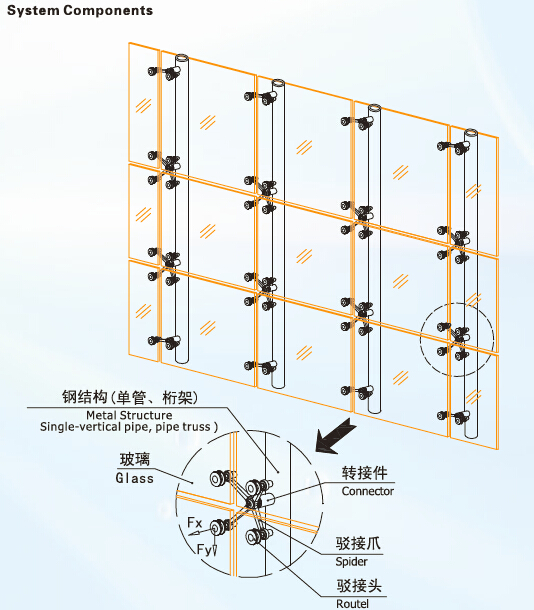

- Steel beams and glass are ready to ensure that the location is not wrong, as well as glass holes, adapter and steel beam welding no problem. Put the claws on the transfer, engage in tight. Put the splice on the glass, engage in tight, do not forget the middle of the gasket. Then, the glass is mounted, the splice is connected with the splicing jaws, but do not twist too tightly, and then adjust the position and adjust the error. Finally, tighten, check the next to ensure safety. Ordinary is so loaded, of course, there are different styles, installation methods are different, but not difficult.

- Q: A set of curtain wall point of the stainless steel access to the claws, including what?

- Point of the curtain wall, a set of four claws, including: a four paw claw pieces, 4 split joints, 1 adapter base. The market is set to sell, and each model, the weight is different, on my information look at it

- Q: The purpose and advantages of splicing claws

- With the rapid development of the construction industry, the facade of the building is also changing, the glass curtain wall by the construction industry is widely used. Glass curtain wall is widely used in various industries. Splicing claws in the glass curtain wall to play a role in convergence, so that a piece of glass into a piece.

- Q: What is the 250 pick up claws

- 250 refers to the hole distance, split the claw is the curtain wall link. The splicing claws offer about $ 300.

- Q: Splicing the claws of the claws

- Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection. Four claws, three claws, two claws 90 degrees, two claws 180 degrees, long claws, short claws, K-type claws,

- Q: Tempered glass can not be broken by a few millimeters

- 8mm above the thickness of the tempered glass can stand, as long as not deliberately hard step, is very strong. I hope my answer can help you, hope to adopt!

- Q: What are the accessories of the point-supported glass curtain wall?

- Mainly to connect joints, splicing claws, adapter, fixture, support rod, cable, rod, etc., what difficulties can say ah, I can help you solve the initial ah

- Q: What is the splice

- Split joint style is divided into: floating head type, countersunk type, sewing type. Floating head is the most commonly used is not expensive. The countersunk head can not see the protruding joints than the glass surface. The stitching of the splice fitting does not require the opening of the glass, but it is more expensive and less widely used.

- Q: Curtain wall windows fixed glass with what accessories

- Glass curtain wall accessories, including splicing claws, plum glass claws, marble pendant and other products 1, by the splicing joints, splicing claws, welding base and other components, split jaws mainly as supporting the joints, and the role of the load to the fixed support structure, is to connect the glass curtain wall is an important accessory. 2, the splicing claws in the glass curtain wall played a role in convergence, through the joints to the load to the steel structure or other body structure, its mechanical properties in this is particularly important. The appearance of the glass curtain wall with the connection of the pawl is transparent, and the interior space and the outdoor environment are fused due to the lack of wall and good lighting. 3, split claw support structure and diverse, to meet the needs of different building structures and decorative effects. Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection.

- Q: Curtain wall decoration line junction how to take a good connection

- With a strong bond strength, crack resistance, anti-hanging, freeze-thaw resistance, waterproof and other effects. Easy to use.

Send your message to us

Splice Routel AJ13

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords