Small Size Flat Cap Routel for Spider AT84

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Name | Small Size Flat Cap Routel for Spider AT84 |

Material | Stainless Steel 304/316. |

Finish | Natural |

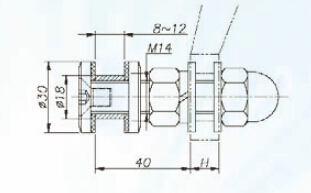

Glass thickness | 8~12mm |

Bolt Size | M14 |

Max. axial bearing capacity | 4500N |

Max. Radial Bearing capacity | 2000N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

- Q:What is a round steel nail on a glass curtain wall?

- You say is the point of the glass curtain wall of the steel claws, you see the circular nails are steel claws through the glass after the floating head or countersunk head

- Q:Curtain wall claw claw how much appropriate? How much is a square? Please professional answer, plus points plus points

- 250 series of four claws of the 480, two claws of the 300, single claw of 190. This is the price is more expensive, Kennedy commonly used splicing a 60 dollars, a base is 60.

- Q:Curtain wall panel installation control points which

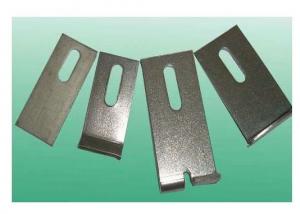

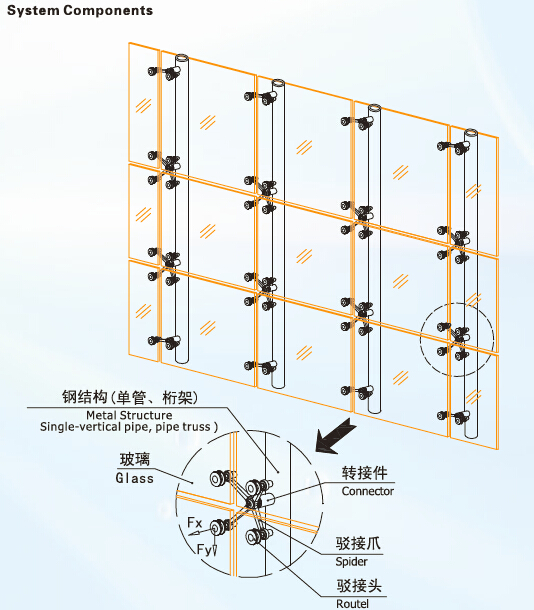

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

- Q:What is the difference between the price of the pick up claw?

- Material 201,304,316, from time to good, the most commonly used is 304. The larger the size, of course, the price is smaller than the size of the expensive

- Q:Stainless steel splicing claws attached to what steel structure above

- Stainless steel splicing jaw pieces of the choice of models to see you mainly use the glass size, carrying the wind pressure, weight.

- Q:304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- Also depends on what size you want. Prices in the tens to hundreds of range. Last month, our company set a number of split claws, manufacturers called Jiangsu Jie Chen, dozens of dollars a set, okay, no rust.

- Q:Who knows which factory is good? Recommended!

- Budget can be considered to find a factory cooperation, our company has worked in Jiangsu Jie Chen, material quality standards, the price is cheap enough, the other do not know, you can find a few and then compare the next decision.

- Q:How many errors can be made by welding the splicing jaws

- To be reasonable at the beginning of the adapter and the steel frame between the contacts designed, I make a simple example: Now there are a lot of steel frame is welded with a round tube, that adapter The base in the production of the time also need to be cut into the arc, so that steel pipe can be better connected to the tube, while reducing the interface of the degree of restraint, and secondly, reasonable arrangement of welding order to reduce the welding stress, Welding at the same time can reduce the heat generated when welding cracks. Welding starting point and the mouth is easy to produce cracks, conditional welding joints should be at the plus arc plate and arc plate. If you can not use the arc plate, the best use of attenuation current arc, and fill the crater. At the same time in the welding process in order to reduce the weld cracks, as far as possible the use of small lines of energy and cross-section of the welding point. If the process of welding found in the leak, if not serious, then gently knock with a hammer may be just fine. To avoid this is best to the workers carefully, in the welding when the cautious point of these problems can be avoided.

- Q:What is the splice

- Is a hardware accessories for the curtain wall

- Q:The difference between the skeleton curtain wall and the whole glass curtain wall

- 1, with a skeleton curtain wall is common aluminum frame, glass inlaid or attached to the keel. Common hidden frame and the box in two ways. 2, the whole glass curtain wall refers to the splicing jaw type of glass installation, the skeleton is the steel structure, glass and skeleton is in two levels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Small Size Flat Cap Routel for Spider AT84

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products