Stainless Steel Wire with Bright Surface/Soft Stainless Steel Coil Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dia.:0.8-8.0mm

Grade: 200, 300, 400series

Type: stainless steel wire

Stainless Steel Spring Wire (SPR)

Application: Springs

Steel grade: 302, 304, 316, 130M, 304ES, 201CU, 631, 200CU, 200CU-3, 200CU-1, D667, etc.

Wire size: 0.2-8.0mm

Surface: Bright, Dull

Temper: as per JIS-WPA, JIS-WPB, and JIS-WPC

Capability: Produced in accordance with the specifications of JIS, with stable linearity and excellent cast and helix, it can be widely used for rolling various precision springs.

Stainless Steel EPQ Wire (EPQ)

Steel grade: 304, 316, 304ES, 200CU-3(Ni: 0.6-0.8%), D667 (Ni: 0.8-1.0%), 200CU (Ni: 1.5-2.0%), 201CU (Ni: 4.1-4.2%)

Diameter: 0.8-8.0mm

Surface: Electro Polishing Quality (EPQ)

Temper: 1/4 hard, 1/2 hard

Capability: With bright surface, slight magnetism and no cracks in forming, it is widely used in manufacturing bicycle fittings, kitchen and sanitation tools, goods shelf, pet cages, grill racks, decorative handles and baskets, food and medical machinery accessories, etc.

Stainless Steel Nail Wire (NAI)

(Application: Kinds of head-shaped, bar-shaped and a nail-shaped stainless steel sharp nails, rivets, volleyball nails

Steel grade: 304, 304HC, 304HCT, 304HC3, 316, 201CU

Wire size: 0.8-8.0mm

Surface: Dull, Bright

Temper: 1/8H, 1/4H, 1/2H

Capability: With high grade wire rod and our most advanced processing technology, we are able to offer you excellent nail wires with the following

Stainless Steel Spoke Wire (SPO)

Grade: 302, 304, 430, 316

Standard: AISI, ASTM, DIN, GB, JIS, SUS

Diameter: 0.8mm-6.35mm

Surface finish: electrolysis bright, bright,

Applications: For manufacture of spokes for cycles, Automobile and car wheels

Characteristics: Bright surface from defects; Correct mechanical properties stable T/S.

Stainless Steel Weaving Wire (WEA)

Steel grade: D667, 200CU-3, 200CU-1, 200CU, 201CU, 304ES, 304, 316

Dia.: 0.2-8.0mm

Application: Welding network, weaving nets, strainers and filter net

Characteristics: Bright surface, uniform toughness, good weaving and braid capability.

Capability: It can be used in weaving general nets, heat resistance belts, and also widely used for Chemical, food processing, petroleum, kitchen utensils, paper and pulp and conveyer belt industries.

Stainless Steel Annealing Wire (ANN)

(Annealing Wire, Re-drawing Wire)

Application: Tie lines, hose connectors, weaving and possession of oil and gas projects

Steel grade: D667 (Ni: 0.8-1.0%), 200CU (Ni: 1.5-2.0%), 201CU (Ni: 4.1-4.2%), 304HC, 304H, 302, 304, 304ES and 316

Wire size: 0.8-8.0mm

Surface: Silvery White

Temper: Soft Annealed

Capability: High re-extend capability and smooth surface, . The expanded usage of high quality fine mesh screening in the filter, printing, automotive, and chemical industries has increased the demand for high grade extra fine wire. The quality of the redraw (annealed) wire has a very significant effect on the production of this very fine diameter wire.

Stainless Steel Cold Heading Wire (CHQ)

(Cold Heading Wire, Screw Wire)

Application: Nuts, bolts, screws, gaskets, frame

Steel Grade: D667, 200CU-3, 200CU-1, 200CU, 201CU, 304ES, 304, 304HC, 304HCT, 304H, 316, 302

Wire Size: 0.8-8.0mm

Surface: Dull, Half Bright

Temper: Soft annealed

Capability: Good shape; Low processing stress; excellent surface quality; Hardening high in the low attrition rate of mold; After the cold forging the low magnetic.

1 | Product Name | stainless steel wire/argon arc welding wire |

2 | Brand | |

3 | Delivery time | 7-14 days after receiving the full payment |

4 | Price | 0-10000 USD/Ton |

5 | Service | 1.Professional engineer advices |

2.Product Warranty is offered | ||

3.OEM, ODM , Customer design | ||

6 | Payment | L/C, T/T |

7 | Ability | 500Ton/month |

Instruction:

The non-rust of the stainless steel means it can have certain chemical stability around the corrosion mediums of air, water, acid, alkali, salt or others. But it does not mean the stainless steel will never rust. Whether the stainless steel will rust or not is influenced by the molecular structures, the processing technic, and the operating environment and so on. To prevent the stainless steel from rusting extremely, please pay attention to the followings:

After many years, we can:

Own design - meet the project needs;

Own production - ensure that the project in a timely manner;

Rigorous testing - ensure good quality;

Dedication to service - ensure customer’s satisfaction;

The whole management - ensure Honor.

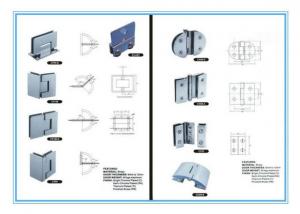

- Q: The installation method of the splicing jaws

- Steel beams and glass are ready to ensure that the location is not wrong, as well as glass holes, adapter and steel beam welding no problem. Put the claws on the transfer, engage in tight. Put the splice on the glass, engage in tight, do not forget the middle of the gasket. Then, the glass is mounted, the splice is connected with the splicing jaws, but do not twist too tightly, and then adjust the position and adjust the error. Finally, tighten, check the next to ensure safety. Ordinary is so loaded, of course, there are different styles, installation methods are different, but not difficult.

- Q: The difference between the skeleton curtain wall and the whole glass curtain wall

- Curtain wall panels and support are glass. The biggest difference between it and the curtain wall is that the skeleton (rib) and the panel are the same glass. Full glass curtain wall of the more transparent.

- Q: What are the specifications of the curtain wall?

- Common specifications for curtain wall claws: Material: 201,304,316; Size: 200,220,250,300;

- Q: Glass curtain wall glass installation process requirements which out

- The first is the preparation before the installation. Stainless steel splicing jaws Before installing, check whether the mounting position of the splicing jaws is accurate. Proof of the steel structure of the main support of the vertical, elevation, beam height and level of compliance with the design requirements, with particular attention to the installation of holes in the review. And then clean the stainless steel and sucker, according to the weight of stainless steel and sucker to determine the number of suction cups. And use the steel brush to clean the surface of the steel tank and the bottom of the groove, the bottom of the stainless steel stainless steel U-shaped steel groove should be added chloroprene rubber pad from the edge of the stainless steel 1/4 width. Field installation of stainless steel splicing claws need to pay attention to the point is due to the specific size of the splicing system size can not be wrong, you must use the torque wrench to determine the torque, the purpose of doing so is to ensure that the joints at the air tightness and watertight Sex. Then install the splice and stainless steel on the mounting platform and install it with the splicing jaws. After the installation of the scene, to ensure that the level of stainless steel deviation within the allowable range, should pay attention to adjust the position up and down about. After all the adjustments are completed, the overall flatness of the facade should be checked to ensure correctness.

- Q: Splicing the claws of the claws

- The appearance of the glass curtain wall with the connection of the pawl is transparent, and the interior space and the outdoor environment are fused due to the lack of wall and good lighting. Split claws support structure and diverse, to meet the needs of different building structures and decorative effects.

- Q: What is the between glass and steel frame?

- There is a thing called the splicing claws, or to tough accessories to ask, they have a frameless curtain wall accessories

- Q: Steel glass canopy glass is tiled or split jaws good

- Light steel glass canopy glass can also be used to strengthen the glass, including light weight, wind load, snow load and live load

- Q: Glass curtain wall claw should be how to calculate the size

- Calculate the area of the curtain wall The number of pieces according to the size of the size of your design depends on the size of the glass block is the number of square four For example, the total building curtain wall 200 square feet, I want to design him with an area of 1 square square glass laying, you need to use 200 pieces of glass, and then each piece of glass jaw is 4 is 800 claw pieces!

- Q: Will the glass curtain wall, 1600 * 2500 glass, 8 +8 glued rubber, with more of the appropriate claw claw, more than 60 meters of the building, so much glass stress enough?

- If it is above the canopy, the general series, such as 220,250 series or even 300 paw pieces are enough, light If it is a facade curtain wall, then it is recommended that you choose the type of heavy-duty claw pieces, remember that the weight of the claw determines the load-bearing, while the corresponding joints to improve the proposed tough or imitation type weight, such as 250 Series of four claws 2.2-2.4kg pure jaw pieces

- Q: 250 type curtain wall glass connection pawls how much punch

- Specifically according to the use and the thickness of the glass with the corresponding fitting, generally can open 40 ~ 50mm hole on the OK, the specific best to consult the supplier to clear the relevant parameters and then open the hole, there are holes to open a little So easy to adjust when the construction.

Send your message to us

Stainless Steel Wire with Bright Surface/Soft Stainless Steel Coil Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords