The Curtain Wall Gasket for Building

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 20000 Sets Per Week set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of The Curtain Wall Gasket For Building

1.material:EPDM Rubber,PVC

2.speciality:ani-aging,acid,water resistence

3.OEM

4.meet GB/T 24498-2009

5.short lead time

Specifications of The Curtain Wall Gasket For Building

1.material:EPDM Rubber,PVC

2.speciality:ani-aging,acid,water resistence

3.OEM

4.meet GB/T 24498-2009

5.short lead time

Features of The Curtain Wall Gasket For Building

Good aging resistance: The aging resistance of EPDM is as well as the Silicone rubber.

Good comprehensive physical mechanical resistance: It shows excellent performance especially the Static Sealing and Dynamic Sealing.

Good corrosion resistance.

Good flexibility : Meet the GB12002-89 standard perfectly.

Good elasticity.

Convenient installation

Competitive price and prompt delivery.

According to customers’ design.

Technical Specifications of The Curtain Wall Gasket For Building

Material: | EPDM,PVC |

Type: | As customers' design |

Producing way: | Extrusion |

Hardness: | 45~75shore |

Color:

| Black,Grey,White or according to customers’ requirements |

Temperature: | -40~+150°C |

Craft: | Best Microwave Vulcanizating |

Packaging: | Woven bag, Carton or according to customers’ requirements |

Function: | For window,door,auto,etc |

Raw material We dedicated to producing good quality products with quality raw material. We import material for EPDM from Holland-DSM,USA-ROYALENE and Dupon,Japan-Mitsui,Germany-Bayer Ag etc.

Production Range of The Curtain Wall Gasket For Building

EPDM/NBR/Silicone/PVC Rubber Seal

EPDM extrusion profile/extrusion side profile

Auto/Car/trunk seal

Door &Window seal

Garage door sealing strip

Silicone seal strip

- Q: Does anyone need a point-like glass curtain wall?

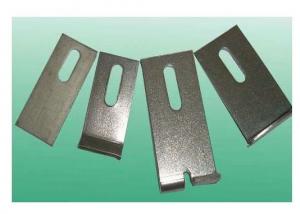

- Point-type glass curtain wall by the decorative glass, split components supporting the composition of the composition.

- Q: What is the difference between the price of the pick up claw?

- With material and size.

- Q: Splicing the claws of the claws

- Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection. Four claws, three claws, two claws 90 degrees, two claws 180 degrees, long claws, short claws, K-type claws,

- Q: What is the difference between steel and glass walls?

- Steel structure glass house and curtain wall is the same? What is the difference, Curtain wall: refers to the glass and special skeleton or parts of the building facade. The main types are: the frame curtain wall, hidden curtain wall, split claw curtain wall. Steel structure of the glass room: the structure of the steel structure of the structure, maintenance of the main material is the glass (which can be glass curtain wall, but may also be other forms) building.

- Q: What is the point of the ribbed curtain wall

- Point refers to the point of the type, the glass panel is fixed by the stainless steel dial system; rib dial refers to the dial system is fixed in the rear of the panel on the floor. The most common is the glass ribs point of the curtain wall.

- Q: The production of curtain wall glass splicing claws of the big brand which several!

- I heard a friend introduced a good with a good, so very good, the price can be, the quality did not say that after all, is a strong sub-brand. Hope to help you.

- Q: The kind of glass that is attached to the pawl, I would like to ask how the size of the glass is accurate? Starting from that point?

- This is very annoying I basically is in the CAD on the painting, more intuitive, just split the middle of the base of the claw (the size is the size of the glass is not buckle), look at the claw claw series (220 series is to Medium size minus 110) and then deduct half a seam, is the hole size. The size of the glass is medium to medium size minus a rubber seam size, rectangular, then so. Irregular shape also need the amount of diagonal. If not the middle of the glass is the edge of the glass is the same way, put their own in the CAD like to know! search for If you want to be accurate point, then do not install the base so that workers in the steel legs on the ball line and then you can cross the line. The intersection of the intersection line is the center of your base.

- Q: Split jaw type 3O0 type open large holes, the glass on the opening of the hole

- Glass hole hole to the glass edge of the 70-hole diameter of 35 upstairs said the same size is wrong Wu each model are single claws

- Q: Glass curtain wall connector (including the base, split joints, split jaws) how much money a set of prices

- Can not give you a certain price, in order to avoid advertising suspicion does not recommend your brand, and try to use the front line, or rust will be very serious, security is also a big problem!

- Q: 304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- 304 stainless steel splicing claw is not expensive, if the amount of large manufacturers suggested that the cooperation, 304 material cost-effective, widely used.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-System nach EN 764-5, Abschnitt 4.2, und AD 2000-Merkblatt W O |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The Curtain Wall Gasket for Building

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 20000 Sets Per Week set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords