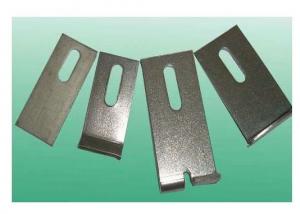

Stainless Steel Marble Bracket/Accessories in Cheap Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Pieces pc

- Supply Capability:

- 1000000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Stainless steel marble bracket

Brand Name: Sity

Model Number: ST-G05

Introduction:

The non-rust of the stainless steel means it can have certain chemical stability around the corrosion mediums of air, water, acid, alkali, salt or others. But it does not mean the stainless steel will never rust. Whether the stainless steel will rust or not is influenced by the molecular structures, the processing technic, and the operating environment and so on. To prevent the stainless steel from rusting extremely, please pay attention to the followings:

1. Stone fixation, stainless steel/Inox

2. Z Restraint/Support bracket/anchor

3. Brackets can be adjustable in 3 directions

1 |

Product Name |

Stainless steel marble bracket/accessories |

2 |

Brand |

|

3 |

Model |

ST-G05 |

4 |

Size |

According to customers' requirements |

5 |

Material |

201, 302, 304, 304L, 316, 316L, according to customers' requirements |

6 |

Standard |

GB, JIS, AISI, BS, DIN |

8 |

Finishing |

Cold draw hairline and Fluorocarbon coating(all kinds of colors) |

9 |

Usage |

stainless steel angle to fix marble stone one the wall |

10 |

Package |

Bubble bag + Inner box + Carton |

11 |

MOQ |

5000 pieces |

12 |

Delivery time |

15-30 days after receiving the full payment |

13 |

Price |

0-100 USD/piece |

14 |

Service | 1.Product design drawings (CAD) |

| 2.Professional engineer advices | ||

| 3.Installation guiding | ||

| 4.Product Warranty is offered | ||

| 5.OEM, ODM , Customer design | ||

15 |

Payment |

L/C, T/T |

16 |

Ability |

1000,000 pieces/month |

Suggestion:

1. Recommended projection size between 45 mm to 135 mm and loads up to 800N.

2. In horizontal joint installation slabs are pinned on the bottom and upper sides. Anchors act as load bearing carrying half the weight of the slabs above. Anchors also act as restraint holding the slabs below and restraining against wind suction and pressure.

3. In vertical joints installation slabs are pinned at the left and right sides. Anchors on the bottom are load-bearing anchors carrying the whole weight of the slab. Half the slab is on the left and half the slab is on the right. Anchors on the top are restraint anchors holding the slabs and restraining against wind suction and pressure.

4. Three - dimensional adjustability allows quick and easy installation.

After many years, we can:

Own design - meet the project needs;

Own production - ensure that the project in a timely manner;

Rigorous testing - ensure good quality;

Dedication to service - ensure customer's satisfaction;

The whole management - ensure Honor.

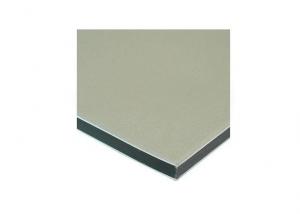

- Q:What is the point of the glass curtain wall and the whole hidden glass curtain wall?

- Point of the glass curtain wall: point of the glass curtain wall, curtain wall glass completely frameless, each piece of glass playing holes inserted into the claws fixed. The interstices are sealed by silicone adhesive. The curtain wall as a whole is neat and soulful.

- Q:Tempered glass can not be broken by a few millimeters

- 8mm above the thickness of the tempered glass can stand, as long as not deliberately hard step, is very strong. I hope my answer can help you, hope to adopt!

- Q:How to install the glass canopy

- Install the stainless steel splicing jaws, and then fixed the size of the glass fixed on the splicing claws, and then hit the weathering glue closed glass gap and glass and wall contact with the gap.

- Q:Steel glass canopy glass is tiled or split jaws good

- Light steel glass canopy glass can also be used to strengthen the glass, including light weight, wind load, snow load and live load

- Q:Viagra Tile 8h005 price

- Split the alias glass claw, the splicing jaws mainly as a support link joints, and transfer load to the fixed support structure system, is to connect the glass curtain wall is an important accessories.

- Q:Clip glass with a handrail pieces of how much money, large amount of where the wholesale right

- Fence on the commonly used type of split pieces are generally 120mm and 160mm

- Q:A set of curtain wall point of the stainless steel access to the claws, including what?

- A set of curtain wall accessories include: such as four claws included, a four paw claw pieces, a adapter base, four split joints, to form a set, in the market are generally complete sets of quotes, but the market The price is expensive outrageous

- Q:What is the connection between the glass room and the stainless steel?

- Sun room known as the glass room, sun room can be built in the complex floor of the terrace, the first floor of the private garden, the top floor of the building, private villas and other places. Its building facade even includes the top, all for the glass structure. Self-built sun room has a lot of problems, summarized as follows: 1, the sun room structure is not strong enough, poor resistance to wind 2, tempered glass blew possible, if blew fall, there may be downstairs owners or pedestrians hurt 3, self-built sun room generally do not do drainage, the rain will follow the foothills, the impact of the owners downstairs, long-term housing facade is not good.

- Q:What are the specifications of the curtain wall?

- One of the most commonly used prices are generally acceptable to 304 material, corrosion resistance is also strong.

- Q:What are the accessories of the point-supported glass curtain wall?

- Mainly to connect joints, splicing claws, adapter, fixture, support rod, cable, rod, etc., what difficulties can say ah, I can help you solve the initial ah

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 CELAB |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | NINGBO,SHANGHAI |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Stainless Steel Marble Bracket/Accessories in Cheap Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Pieces pc

- Supply Capability:

- 1000000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords