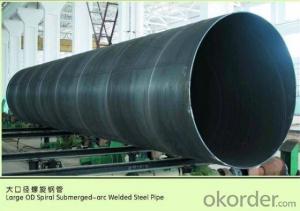

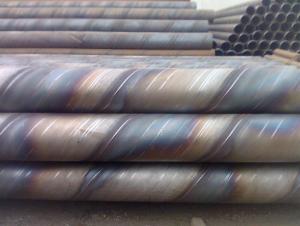

SPIRAL WELDED STEEL PIPE 16/18/20/22/24/26/28'' CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: How are steel pipes threaded for connection?

- Steel pipes are threaded for connection using a threading machine or a die. The pipe is clamped securely into the machine, and a rotating die is then used to cut threads into the pipe's surface. This process creates the necessary grooves and ridges that allow the pipes to be securely connected together.

- Q: What is hot rolled steel pipe? What is a cold drawn steel tube?

- Hot rolling is relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.

- Q: What does GALV mean in a steel tube?

- GALV is the abbreviation of English galvanized (Galvanized), which means galvanized steel pipe.

- Q: What is the average lifespan of a steel pipe?

- The average lifespan of a steel pipe can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, with proper installation and maintenance, a steel pipe can typically last anywhere from 20 to 100 years.

- Q: Can steel pipes be used for underground cooling systems?

- Yes, steel pipes can be used for underground cooling systems. Steel pipes are commonly used in various applications, including underground cooling systems, due to their durability, strength, and resistance to corrosion. They can effectively handle the high pressure and temperature demands of cooling systems. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance. However, it is important to ensure that the steel pipes are properly coated or insulated to prevent corrosion and maintain efficiency in heat transfer.

- Q: How are steel pipes measured and specified?

- Steel pipes are measured and specified using several key parameters. The most common ones include the outer diameter (OD), wall thickness, and length of the pipe. The outer diameter refers to the measurement of the pipe's outside surface from one end to the other. It is typically expressed in millimeters (mm) or inches (in), and it plays a critical role in determining the pipe's strength and carrying capacity. Different applications require different OD sizes, which can range from a few millimeters to several feet. The wall thickness of a steel pipe refers to the distance between its outer and inner surfaces. It is measured in millimeters or inches and is crucial for determining the pipe's durability and resistance to pressure. Thicker walls can handle higher pressure, making them suitable for applications that require transporting liquids or gases under high pressure. The length of steel pipes is generally specified in meters or feet. Standard pipe lengths are often 6 or 12 meters (20 or 40 feet), but custom lengths can be requested based on project requirements. It is important to note that longer pipes may require additional support to prevent sagging or structural issues. Apart from these primary measurements, steel pipes may also be specified based on other factors such as material grade, manufacturing standard, and surface finish. Material grade refers to the quality and composition of the steel used in the pipe, which determines its strength and corrosion resistance. Manufacturing standards, such as ASTM or API, ensure that the pipes meet specific quality and performance criteria. Surface finish specifications may include factors like galvanized coating, which provides protection against corrosion or other specific requirements based on the intended application. Overall, the measurement and specification of steel pipes involve considering the outer diameter, wall thickness, length, material grade, manufacturing standard, and surface finish. These parameters are crucial in determining the suitability of the pipe for various applications and ensuring its performance and durability in different environments.

- Q: What is the difference between steel pipes and copper pipes?

- Steel pipes and copper pipes differ in terms of their material composition, with steel pipes being made of steel and copper pipes being made of copper. Steel pipes are generally stronger and more durable, making them suitable for high-pressure applications and underground installations. Copper pipes, on the other hand, have excellent heat conductivity and corrosion resistance, making them ideal for plumbing and heating systems. Additionally, copper pipes are more expensive than steel pipes but offer better resistance to bacteria growth. Ultimately, the choice between steel and copper pipes depends on the specific needs and requirements of the application.

- Q: How are steel pipes used in nuclear power plants?

- Steel pipes are extensively used in nuclear power plants for various purposes. They are primarily used for the transportation of coolant, such as water or gas, which helps in removing heat from the reactor core. Steel pipes are also used to convey steam generated by the reactor to the turbine, where it is used to generate electricity. Additionally, steel pipes are utilized for the transportation of various fluids, such as lubricants and chemicals, for different processes within the plant. The durability, strength, and resistance to high temperatures and pressure make steel pipes an ideal choice for these critical applications in nuclear power plants.

- Q: How do steel pipes perform in marine environments?

- Steel pipes perform well in marine environments due to their high strength and corrosion resistance. The protective oxide layer formed on the surface of the steel helps prevent rust and deterioration caused by salty sea air and water. Additionally, steel pipes can withstand the high pressure and temperature fluctuations commonly found in marine applications, making them a reliable choice for transporting fluids and gases in offshore structures, ships, and other marine installations.

- Q: How are steel pipes used in the construction of power transmission lines?

- Due to their exceptional strength, durability, and versatility, steel pipes are commonly utilized in the construction of power transmission lines. Throughout the project, these pipes serve various purposes that contribute to the overall efficiency and reliability of the power transmission system. One primary application of steel pipes in power transmission line construction involves the installation of transmission towers. These pipes function as structural components, providing support for the transmission lines and maintaining their alignment. The high strength of steel ensures that the towers can withstand the weight of the transmission lines, as well as external forces like wind and ice loads. Additionally, steel pipes offer excellent resistance against corrosion, which is vital for ensuring the longevity of the transmission tower structures. Apart from tower construction, steel pipes are also utilized in underground transmission lines. These pipes act as conduits for the cables, safeguarding them from external elements and potential damage. Steel pipes are particularly advantageous in this application due to their ability to resist soil movement, withstand high pressure, and provide a secure pathway for the power cables. Moreover, the durability of steel ensures the integrity and longevity of the underground transmission lines, reducing maintenance needs and enhancing the overall reliability of the power transmission system. Furthermore, steel pipes are employed in the construction of foundations and anchors for transmission towers. These pipes are driven deep into the ground to offer stability and support to the towers. The inherent strength and rigidity of steel pipes make them ideal for this purpose, as they can withstand heavy loads and ensure the stability of the transmission towers even in adverse weather conditions. In conclusion, steel pipes play a critical role in power transmission line construction by providing structural support, protecting cables, and ensuring the overall reliability and efficiency of the transmission system. The exceptional strength, durability, and resistance to corrosion make steel pipes the ideal choice for power transmission line construction projects.

Send your message to us

SPIRAL WELDED STEEL PIPE 16/18/20/22/24/26/28'' CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords