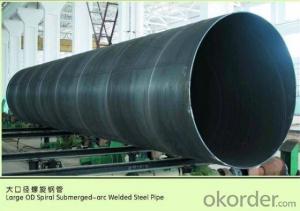

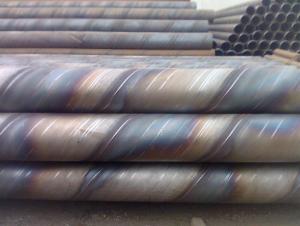

SPIRAL WELDED STEEL PIPE 12‘’ 36‘’ 48‘’ CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: Can steel pipes be used for the construction of offshore platforms?

- Yes, steel pipes can be used for the construction of offshore platforms. Steel pipes are commonly used in offshore platform construction due to their high strength, durability, and resistance to corrosion. These pipes can be used for various purposes such as structural support, transporting fluids, and as conduits for electrical and communication systems. Additionally, steel pipes can be easily fabricated, installed, and maintained, making them a reliable choice for offshore platform construction.

- Q: Can steel pipes be used for underground telecommunications networks?

- Indeed, underground telecommunications networks can utilize steel pipes. The strength, durability, and corrosion resistance of steel pipes make them a prevalent choice for underground applications. These pipes offer both protection and support for telecommunication cables, effectively enduring the pressure and load exerted underground. Moreover, applying protective coatings to steel pipes can augment their corrosion resistance and prolong their lifespan. All in all, steel pipes prove to be a dependable option for underground telecommunications networks.

- Q: How are steel pipes used in the construction of underground parking structures?

- Steel pipes are commonly used in the construction of underground parking structures for various purposes. They are primarily utilized for the installation of underground drainage systems, including stormwater and wastewater pipes. Steel pipes are also employed for the construction of support columns and beams, providing structural stability to the parking structure. Additionally, steel pipes are used for the installation of fire protection systems, such as sprinkler pipes, ensuring the safety of the underground parking facility.

- Q: How do steel pipes handle water erosion?

- Steel pipes are highly resistant to water erosion due to their inherent strength and durability. The smooth surface of steel pipes minimizes friction and turbulence, reducing the likelihood of erosion. Additionally, steel pipes can be coated with protective layers, such as galvanization or epoxy, that further enhance their resistance to water erosion.

- Q: What are the industries that commonly use steel pipes?

- Some of the industries that commonly use steel pipes include construction, oil and gas, water and wastewater treatment, mining, manufacturing, automotive, and infrastructure development.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. Steel pipes are durable, corrosion-resistant, and have a long lifespan, making them ideal for handling the harsh conditions and corrosive substances found in sewage systems. Additionally, steel pipes offer high strength and are capable of withstanding high-pressure flows, making them a reliable choice for sewage treatment plants.

- Q: How are steel pipes insulated to prevent heat gain?

- Steel pipes are typically insulated using materials such as fiberglass, foam, or mineral wool. These insulation materials are wrapped around the steel pipes to create a barrier that reduces heat transfer. The insulation helps to prevent heat gain by minimizing thermal conductivity and keeping the temperature of the pipes stable, which is crucial for maintaining the integrity and efficiency of various industrial processes.

- Q: What is the meaning of "DN" and "Phi" in the dimensioning of steel pipe diameter and how to apply the mark?

- DN is a kind of Engineering path, not the actual value, due to the different standards, so the actual corresponding values is not the same; phi is refers to the actual value, the same national standard pipe inside the steel pipe, the actual value is the same, for example, GB/T8163 and GB GB fluid pipe spiral pipe and GBT/T9711.1 GB/T12459 the same nominal diameter corresponding to the actual value is the same as the actual value; and American Standard steel standard ANSI B 16.38 and ANSI B 16.9 standard American Standard fitting the same nominal correspondence is the same. If marked, the nominal diameter should be added DN, and the actual value can be omitted.

- Q: Can steel pipes be used in high-pressure applications?

- Yes, steel pipes can be used in high-pressure applications. Steel pipes are known for their strength and durability, making them suitable for handling high pressures in various industries such as oil and gas, water distribution, and chemical processing.

- Q: Are steel pipes resistant to earthquakes?

- Compared to other materials like concrete or PVC pipes, steel pipes are commonly regarded as more resistant to earthquakes. This is because steel possesses inherent properties such as high tensile strength and flexibility. These properties enable steel pipes to effectively absorb and distribute seismic energy during an earthquake, enabling them to endure shaking and ground movements more effectively. Moreover, steel pipes have the capability to deform without rupturing or collapsing, reducing the risk of structural failure. However, it is crucial to note that the earthquake resistance of steel pipes ultimately relies on various factors including the design, installation, and overall structural integrity of the piping system. To ensure the highest level of earthquake resistance for steel pipes, it is imperative to adhere to proper engineering and construction practices.

Send your message to us

SPIRAL WELDED STEEL PIPE 12‘’ 36‘’ 48‘’ CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords