Raw Materials for Refractory:Specialised Refractory Castables for Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Customised solutions for your kilns

2.repair service

3.furnace construction service

4.high mechanical strength

5.ISO9001

1)Refractories for insulation of furnaces and kilns

2)Refractories to meet high-temperature erosion / corrosion

3)Refractories to take high-temperature loads

4)Refractories for continuing improvement in production & performance

5)Refractories for cost-effective manufacturing solutions

Physical & Chemical Properties of Refractory LH-85B

Product Name | Specialized castable for coal burner tube | Corundum Andalusite Castable For Burner | |||

Product Code | LH-80P | LH-85P | LH-70P | ||

Density(kg/m3) | ≥2.75 | ≥2.75 | ≥2.60 | ||

Chemical Component (%) | AL2O3+SiC | ≥75 | ≥80 | ≥70 | |

Cold Crushing Strength(MPa) | 110°C*24h | ≥90 | ≥90 | ≥80 | |

1100°C*3h | ≥100 | ≥110 | ≥90 | ||

1350°C*3h | ≥100 | ≥120 | ≥85 | ||

Modulus of Rupture(MPa) | 110°C*24h | ≥9 | ≥10 | ≥7 | |

1100°C*3h | ≥11 | ≥12 | ≥7 | ||

1350°C*3h | ≥12 | ≥13 | ≥10 | ||

Linear Change Rate(%) | 1100°C*3h | ±0.3 | 0.25± | ± 0.3 | |

1350°C*3h | ± 0.4 | ±0.4 | ±0.4 | ||

Maximum Service Temperature(°C) | 1600 | 1650 | 1600 | ||

Construction Method | Pouring& Vibrating | ||||

Application Area | Coal burner tube and high-temperature parts | ||||

Construction Service & Regulations

1.Check the size, specification, layout, installation and quality of the metal anchorage and make expansion

processing of the anchors.

2.Erect the formworks (hardwood or steel) in advance.

3.Unpacking and pouring the castable

4.Mixing

5.Installation of the mixed castables & Large area constrction

6.Vibrating

7.Before the castable block get final set,it can not bear any pressure or vibration.

8.Curing & Stripping

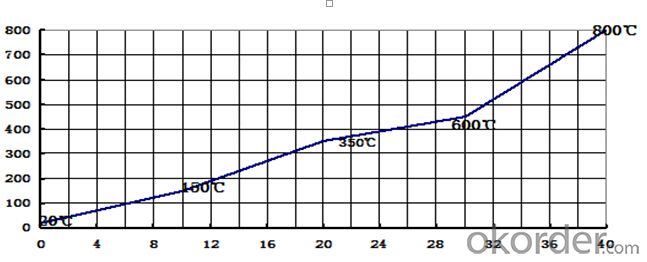

9.Baking the Furnaces (taking cement plant kiln as an example):

1). Keep the initial temperature at 20°C or so.

2). Please strictly follow the curve to conduct the baking work and increase the temperature smoothly and

evenly.

3). Lay out as many temperature measuring points as possible to monitor the temperature in the kiln, ensuring

the stable increase of the temperature.

FACTORY:

- Q: Who know what kind of fire shutter fire rating are there?

- Fire resistance rating of the building elements is different due to the different requirements of the construction . Fire proof door can be divided into Serie A, B and C in terms of fire endurance limit, fire resisting limit are not should be less than 1.20h, 0.90h and 0.60h. That is, if the fire resistance rating is two, also it is possible to use a class a fire door. Hope my answer will help you.

- Q: What is the upper temperature limit for refractory materials?

- The key depends on what refractories you use

- Q: What's the feature of construction external wall fireproof and thermal inuslation matertial?

- Building external wall fireproof thermal insulation material is made by stirring, casting, foam protecting and cutting with industrial by-product gypsum as the main raw material, adding sulphate aluminium cement, fly-ash, polymer additives and other materials. It has excellent properties of respiratory function , air permeability, water impermeability, recycling system data, wind load resistance, shock resistance, thermal insulation, fireproof and sound insulation.

- Q: What's the texture of refractory for the hearth of reverberatory?furnace? ?

- The long-term usage temperature of ceramic fiber is between 950-1260 degrees.

- Q: Who knows the model of fireproofing materials?

- Models of fireproofing material: PC 6555 Bayer 6555 fireproofing PC 6557 Bayer 6557 fireproofing PC 6485 Bayer 6485 fireproofing PC 6385 Bayer 6385 fireproofing PC 6265 Bayer 6265 fireproofing PC 2865 Bayer 2865 fireproofing PC 4610 Dow 4610. Hope my answer will be helpful to you!

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- This is the use of steel tapping water procedures inside!!

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: What are the main characteristics of the sic refractories?

- 1. The usge temperature of silicon carbide refractory is generally 1760 ℃ 2. The silicon carbide refractories can withstand the dramatic changes of temperature and have a good thermal shock resistance performance. To prevent the cracking or breaking of lining refractories. 3. Under the conditions of high or low temperature, it can withstand a certain compressive stress. 4. Under the conditions of high or low temperature, it can withstand friction. 5. It can withstand the huge hydraulic pressure or buoyancy of the metal. 6. It can also withstand the effect of furnace gases to prevent the infiltration of other refractories and reactions.

- Q: The manufacturing technique of refractory material

- Melt blowing method is to melt the ingredients first, In addition, hiphotos, organic impurities, to be mixed, add sulfite pulp waste liquid into magnesia billet , ensure the accuracy of the product dimension. The products are mainly used for light refractory. then dry and fire with sintering to reduce the firing shrinkage of products, making it disperse into fiber or hollow sphere. The porpose of pre sintering raw material is to Sintering method is pre-sintering part of the raw material into clinker. such as adding binding clay into aluminum silicate blank

Send your message to us

Raw Materials for Refractory:Specialised Refractory Castables for Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords