High Temperature Castable Refractory Cement - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 40000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

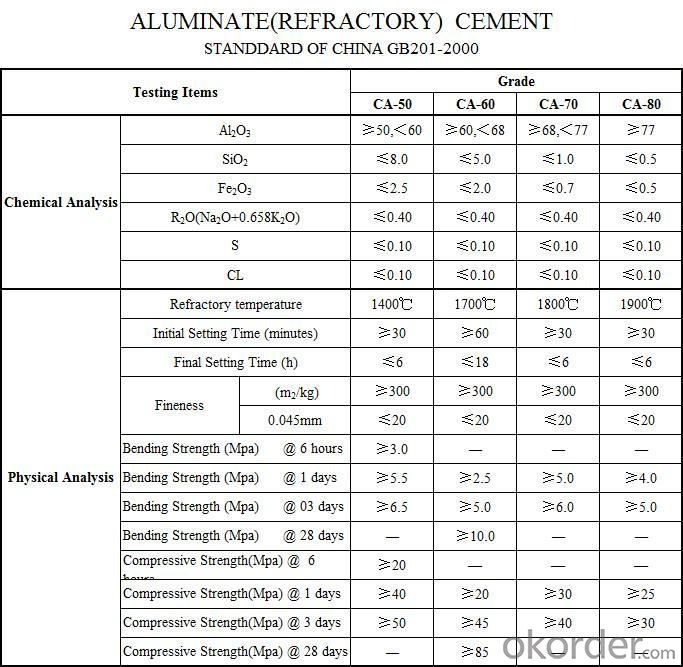

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM | Model Number: | CA-50 |

| Color: | Brown | Feature: | Refractory | Main Raw Material: | Aluminate |

| Type: | refractory cement | Hardening Feature: | Rapid Hardening | Heat of Hydration: | Moderate Heat |

| type: | Refractory cement | Al2O3: | ≥50<60< p=""> | Refractory temperature: | 1400 ℃ |

Packaging & Delivery

| Packaging Details: | a) 50kg per bag then 40 bags into a 2mt sling bag for portland cement 42.5R b) 2mt jumbo bag of portland cement |

| Delivery Detail: | within 25 days after received payment |

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | QIHAN | Model Number: | CA-50 |

| Color: | Brown | Feature: | Refractory | Main Raw Material: | Aluminate |

| Type: | refractory cement | Hardening Feature: | Rapid Hardening | Heat of Hydration: | Moderate Heat |

| type: | Refractory cement | Al2O3: | ≥50<60< p=""> | Refractory temperature: | 1400 ℃ |

Packaging & Delivery

| Packaging Details: | a) 50kg per bag then 40 bags into a 2mt sling bag for portland cement 42.5R b) 2mt jumbo bag of portland cement |

| Delivery Detail: | within 25 days after received payment |

Specification

Packaging & Shipping

“ Come on! you need try and trust ”

We are forwarding hand in hand together, win-win future!

We always provide the best service!

SGS inspection before shipment

- Q: How much is refractory spraying coatings?

- Different brands and models have different prices. For example: Refractory temperature: 1580 ~ 1770 ℃ | Brand: Hengli | Product category: dedicated castable for biomass burning machine | Material: castable Price: 3000.00 refractory temperature: 1770 ~ 2000 ℃ | Brand: Great Wall | Category: unshaped refractory material | Material: corundum mullite Price: Refractory temperature: 1580 ~ 1770 ℃ | Brand: Guanghuayaoye | Product category: refractory material| Material: high alumina Price: 2500.00 The above prices obtained from the Internet are for reference only, and please pay attention to the purchasing price.

- Q: What is the principal part of silicious refractory material

- blast furnace hot blast stove and ceramic tunnel kiln vault, etc., the softening temperature under a fixed load is high (1690-1710 degree), glass melting furnace, lightweight silica bricks and generally the silicon?dioxide is greater than 93% and used above the 600 degree. I had undertaken to complete the 50,000 tons over two advanced silica brick production line design. It is a typical acidic refractory. At present, it is mainly used to coke oven which the masonry operating temperature is higher than 600 degree, with good acid resistance of slag erosion, including silica?brick, good thermal conductivity, high thermal vibration stability, product with fused quartz, close to its refractoriness silicious refractory SiO2 which is as the main component of refractory products.

- Q: What are the requirements of the performances of brasque refractory?

- The requirements of the performances of brasque refractory: 1, should have sufficient refractoriness and softening point under a fixed load. Because under the action of the electric arc, the inner and surface temperature of the different parts of the brasque can be up to 1500 ~ 1800 ℃. 2, should have strong slag resistance. Because the inward permeation of slag and smoke at high temperature through its pores of brasque cause melting loss of refractories, organization delamination and flaking. 3, should have good thermal shock resistance. Because in the steelmaking process, opening the furnace door, lifting the furnace lid will cause sudden temperature change of brasque refractory,flaking and cracking, resulting in premature failure of brasque. 4, should have sufficient strength, because the brasque will be impacted at the time of loading, vibrated when tilting, flushed by metal, slag and gas flow when boiling. 5, the thermal conductivity and the conductivity should be small. Refractories commonly used for electric furnace include magnesia bricks, dolomite brick, high-alumina refractory bricks, silicious refractory brick and magnesite ramming material. Due to the different working environment of each parts of the furnace, refractories are different.

- Q: How to classify the grade of wall fireproof and thermal inuslation matertial?

- External wall thermal insulation materials are mainly divided into grade A, grade B1, grade B2 and grade B3. In accordance with the current "Combustion Performance Classification Method of Building Materials", grade A thermal insulation material is incombustible?material and belongs to inorganic heat preservation material. However, grade A thermal insulation material is few in terms of the current market. There are only JETCO YT inorganic active wall thermal insulation material, glass wool, rock wool board, foam glass, vitrified micro bead and grade A fireproofing thermal insulation board. However, compared with grade A thermal insulation material, the more welcomed by the market is the organic insulation materials. Thermal insulation material that is determined as grade B is divided into three levels. Grade B1 is grade is flame retardant. Grade B2 is combustible. Grade B3 is flammable.

- Q: Refractory factory grinding brick dust harmful to the body?

- The effect is very large and belongs to lung disease.

- Q: Does anyone know which materials belong to light fire resistant material?

- Building board of lightweight fireproof partition material: 1, GRC lightweight partition material glass fiber reinforced concrete; it is a kind of fiber cement composite with alkali-resistant glass fiber as reinforced material and cement mortar as the base material . Aerated concrete block equipment foundation construction Its outstanding features are having good tensile, rapture strength and good toughness. This kind of material is particularly suitable for the production of ornament mould and the manifestation of strong texture. Compared with these external wall decorative materials, the biggest advantage of GRC material is to meet the individual needs of architects, completing the expression of various ornament moulds and skin textures. 2, fiber reinforced low alkalinity cement building plate. The standards stipulate the classification, raw materials, technical requirements, test methods, inspection rules, packaging, labeling, transport and storage of the fiber reinforced low alkalinity cement building plate.

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- You'd better oxidize magnesia preformed unit at room temperature for a longer period of time, then bake it, during which, it's enough to control the maximum temperature within 300 degrees. During the middle process, usually heating up for 4 hours and keep warm for 3 hours. The entire heating up process takes about 20 hours. If it is the site operation magnesia-based castable, it should be heated slowly in the early stage, and pay attention to keeping warm at 80 degrees Celsius. Every manufacturers has their own heating curves, so do not blindly adopt existing curves, try to make your own heating curve.

- Q: How to choose refractory material

- Refractory fiber in different furnace material requirements are different, I would like to know is methanol as a protective gas, fire fiber, cotton material what?.

- Q: Manganese steel belongs to refractories

- NO!

- Q: Who can tell me the properties and classification of insulating refractories?

- Bubble method. This method is the foam agent in a frothing machine mixing with water and prepared uniform fine foam, the foam added in common mud mixing into the foam slurry injection model, together with the drying, demoulding, at 1320 DEG C to 1380 DEG C (high alumina insulating refractory brick for burning) after processing, the plastic products.

Send your message to us

High Temperature Castable Refractory Cement - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 40000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords