Smooth Two Coat Finish Aluminum Coil for Cable Shield with High Quality and Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Coil for Cable Shield with High Quality and Cheap Price

l Product Introduction

Alloy: 1000 series, 3000 series, 8000series

Temper: O H22 H24 H26 H28

Apply: bill board, selectronic circuit board, building exterior decoration, curtain wall plate,reflective devices,etc.

Thickness: 0.2-2.0mm

Length: 1000-6000mm

Width: 1100-1700mm

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| 1100, 1050, 3003, 8011 | 0.2-2.0 | 1100-1700 | 1000-6000 | O, H22, H24, H26, H28 | |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

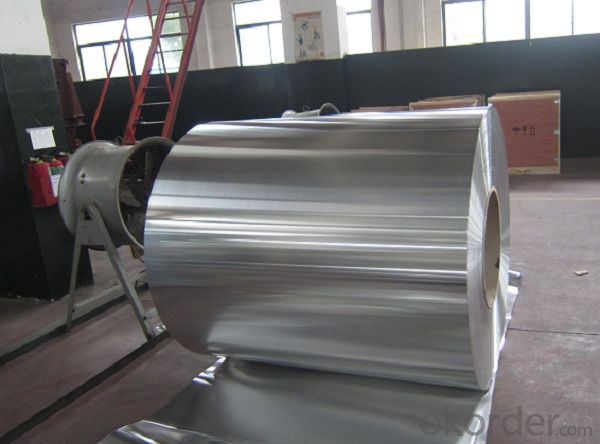

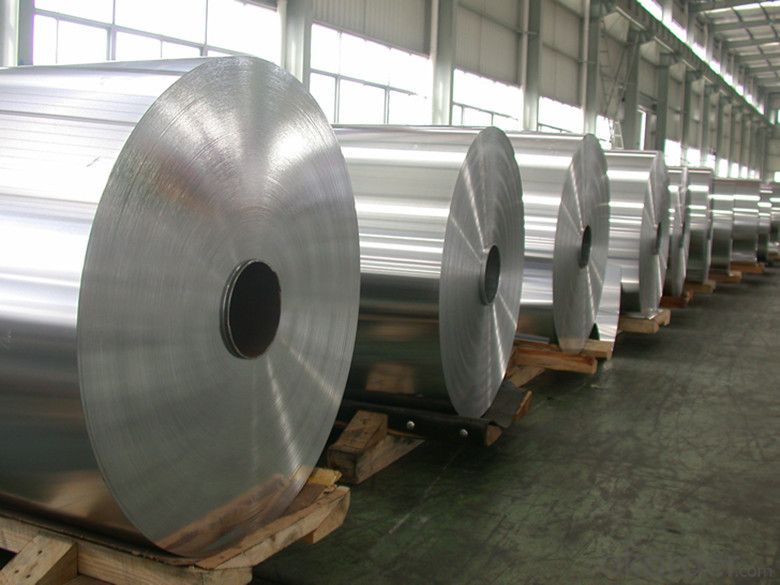

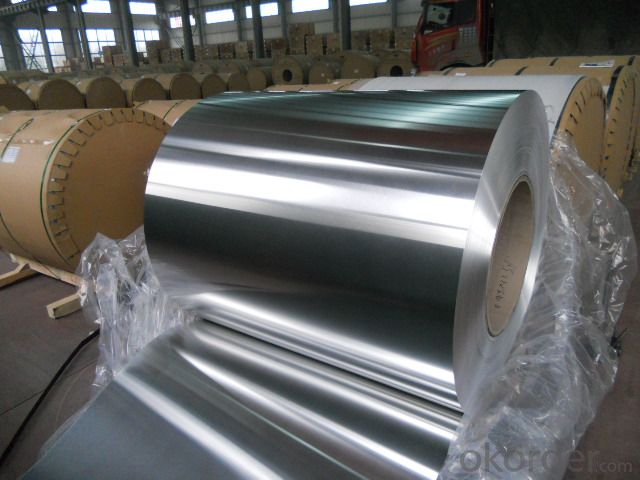

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Are aluminum coils suitable for solar reflectors?

- Yes, aluminum coils are indeed suitable for solar reflectors. Aluminum has high reflectivity, making it an ideal material to redirect and focus sunlight onto solar panels or other solar energy systems. Its lightweight nature and resistance to corrosion also make it a practical choice for solar reflectors.

- Q: What are the potential applications of coil-embossed aluminum coils?

- Some potential applications of coil-embossed aluminum coils include building and construction materials, such as roofing and siding, as well as decorative elements for interior design. Additionally, these coils can be used in the manufacturing of appliances, automotive parts, and packaging materials, due to their durability, aesthetics, and corrosion resistance.

- Q: What are the different edge profiles available for aluminum coils?

- There are several different edge profiles available for aluminum coils, each serving a specific purpose or aesthetic preference. Some of the most common edge profiles include: 1. Square Edge: This is the most basic and straightforward edge profile, with sharp corners and a flat surface. It is often used for industrial applications where functionality is prioritized over aesthetics. 2. Round Edge: The round edge profile features a curved surface that eliminates sharp corners. This profile is commonly used in applications where safety is a concern, such as automotive parts or children's playground equipment. 3. Beveled Edge: The beveled edge profile is characterized by a slanted or angled surface. It is often chosen for architectural purposes, as it adds a sleek and modern look to aluminum coils. Additionally, the beveled edge helps to minimize the risk of sharp edges and potential injuries. 4. Full Radius Edge: This edge profile features a smooth, rounded surface that extends along the entire length of the coil. Full radius edges are often preferred for applications where the coil will come into contact with other materials, as they reduce the risk of damage or scratching. 5. Hemmed Edge: A hemmed edge is created by folding the edge of the coil back onto itself, resulting in a double layer of metal. This profile is commonly used in applications where a strong and durable edge is required, such as in the manufacturing of appliances or cabinets. 6. Tapered Edge: The tapered edge profile gradually narrows the width of the coil towards the edge, creating a tapered or sloping appearance. This profile is often chosen for architectural or decorative purposes, as it adds visual interest and can make a space appear more dynamic. It is important to note that the availability of these edge profiles may vary depending on the manufacturer and the intended application of the aluminum coil. Therefore, it is recommended to consult with the supplier or manufacturer to determine the specific edge profiles that are available for a particular coil.

- Q: This question asks for methods to determine whether an aluminum coil is new or old.

- <p>To determine if an aluminum coil is new or old, you can look for several signs: 1. Surface appearance: New coils typically have a clean, smooth surface without scratches or discoloration. 2. Packaging: New coils are usually well-packaged and protected. 3. Manufacturing date: Check for any labels or markings that indicate the manufacturing date. 4. Quality of the material: New coils should have consistent thickness and no signs of corrosion or wear. 5. Performance: New coils should perform as expected without any issues. If you're still unsure, consider consulting with a professional or the supplier for more information.</p>

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a] AL is used to make frames because it is light, not costly and strong.

- Q: Can aluminum coils be used in solar energy systems?

- Certainly, solar energy systems can utilize aluminum coils. Aluminum is widely employed in the fabrication of solar panels and solar energy systems owing to its remarkable qualities. Lightweight, durable, and possessing excellent thermal conductivity, aluminum coils are perfect for dispersing heat away from solar cells. Moreover, aluminum's resistance to corrosion is essential for outdoor deployments, where solar panels face diverse weather conditions. By incorporating aluminum coils into solar energy systems, the efficiency and lifespan of the panels are enhanced, thus augmenting the efficacy and sustainability of solar energy generation.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum coil in insulation applications.

- <p>Aluminum coil has several advantages for insulation, including its high thermal conductivity, which allows for efficient heat transfer, and its lightweight nature, making it easy to handle and install. It also offers good resistance to corrosion and is cost-effective compared to other materials. However, it has some disadvantages such as low strength, which may require additional support structures, and it can be prone to denting or damage if not handled carefully. Additionally, aluminum's high conductivity can lead to increased heat loss if not properly insulated, and it may require more frequent maintenance due to its susceptibility to environmental factors.</p>

- Q: What are the weight and thickness options for aluminum coils?

- The weight and thickness of aluminum coils can differ based on specific requirements and applications. There is a wide range of weight and thickness options available for aluminum coils to meet the needs of different industries. In terms of weight, aluminum coils are offered in various choices including light gauge, standard gauge, and heavy gauge. Light gauge aluminum coils generally have a thickness ranging from 0.006 to 0.025 inches and are commonly utilized in industries that require lightweight materials like packaging, electronics, and automotive components. Standard gauge aluminum coils are slightly thicker, ranging from 0.026 to 0.063 inches, and are often used in construction, roofing, and transportation applications. Heavy gauge aluminum coils are the thickest option, typically measuring 0.064 inches and above, and are frequently employed in heavy-duty applications such as aerospace, marine, and industrial equipment manufacturing. As for thickness, aluminum coils are available in various options as well. The thickness is usually measured in inches or millimeters, and the range can vary from as thin as 0.006 inches (0.15 mm) to as thick as 0.25 inches (6.35 mm) or even higher for specific applications. The suitable thickness of the aluminum coil depends on the intended use and the desired level of structural strength or flexibility required. It is important to note that these weight and thickness options may differ depending on the manufacturer and the specific aluminum alloy utilized. It is always advisable to consult with the manufacturer or supplier to determine the most appropriate weight and thickness options for your specific application.

- Q: This question asks about the distinctions among various grades of aluminum coils, likely referring to their properties and uses.

- <p>Aluminum coils are differentiated by grades based on their alloy composition, thickness, and specific applications. Common grades include 1000 series (99% pure aluminum, soft and malleable), 3000 series (aluminum-manganese alloys, good for cooking utensils), 5000 series (aluminum-magnesium alloys, used in marine applications), and 6000 series (aluminum-magnesium-silicate alloys, known for strength and used in construction). Each grade has distinct properties such as strength, formability, and corrosion resistance, which determine their suitability for different industries and applications.</p>

- Q: How can aluminium ingots be processed into aluminium coils (aluminium sheets)?

- This depends on what kind of ingot, and if it is small, it needs to be melted into a furnace, cast into a large plate, and then rolled on a mill

Send your message to us

Smooth Two Coat Finish Aluminum Coil for Cable Shield with High Quality and Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords