Smooth Two Coat Finish Glossy RAL Color Coated Aluminum Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Glossy Ral Color Coated Aluminum Coil Description:

Glossy Ral Color Coated Aluminum Coil is Mainly used in signs, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect。Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set

2.Main Features of Glossy Ral Color Coated Aluminum Coil:

- High gloss;

- Wide range of color ;

- Good mechanical processing performance;

- Impact and weather resistance;

- Easy for processing and installation;

- Excellent torsion strength

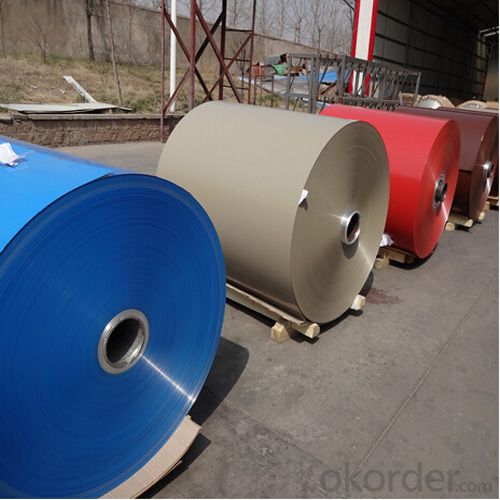

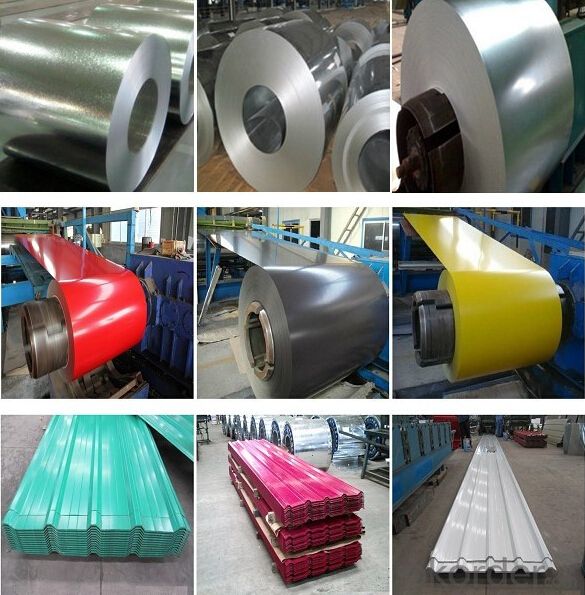

3. Glossy Ral Color Coated Aluminum Coil Images:

4. Glossy Ral Color Coated Aluminum Coil Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Temper | |

| A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A3003,A3004,A3105 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A6061,A6082,A6063 | 0.8-3.0 | 20-1900 | O | |

| A8011,A1145,A1235 | 0.005-0.2 | 20-1700 | O,,H18,H24 | |

| ID | 76mm,152mm,200mm,300mm,505mm | |||

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum coils be used in solar panel installations?

- Indeed, solar panel installations can make use of aluminum coils. The lightweight properties, corrosion resistance, and remarkable thermal conductivity of aluminum make it a favored material for constructing solar panels. Frequently, aluminum coils are employed as the supportive backing material for solar panels, ensuring both structural stability and effective heat dissipation. Additionally, these coils are commonly utilized in the production of solar mounting systems, which securely hold the panels in position. All in all, aluminum coils present a dependable and efficient choice for solar panel installations.

- Q: What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils have numerous potential applications across various industries. One of the primary uses of anodized aluminum coils is in the construction industry. They are commonly used for cladding and façade systems, as the anodized coating enhances the durability, weather resistance, and aesthetic appeal of the aluminum. Anodized aluminum coils can withstand harsh environmental conditions, such as UV radiation, saltwater exposure, and extreme temperatures, making them an ideal choice for building exteriors. Another significant application of anodized aluminum coils is in the automotive industry. The anodized coating provides a protective layer that enhances the corrosion resistance of aluminum, making it suitable for various automotive components. It can be used for trim, body panels, window frames, and other parts that require both durability and an attractive appearance. Anodized aluminum coils also find use in the manufacturing of consumer electronics. The anodized coating improves the scratch resistance, electrical insulation, and heat dissipation properties of aluminum, making it suitable for electronic enclosures, heat sinks, and connectors. Additionally, the vibrant colors that can be achieved through anodization allow for customizable designs that appeal to consumers. Due to its lightweight nature and excellent heat conductivity, anodized aluminum coils are extensively used in the heating, ventilation, and air conditioning (HVAC) industry. They are commonly used for heat exchangers, air conditioning coils, and evaporator coils. The anodized coating provides protection against corrosion caused by moisture and other environmental factors, ensuring the longevity and efficiency of these HVAC components. Furthermore, anodized aluminum coils have applications in the food and beverage industry. The anodized coating provides a hygienic surface that is easy to clean and resistant to bacterial growth. It is used for food processing equipment, storage tanks, and packaging materials, ensuring the safety and quality of the products. Overall, the potential applications of anodized aluminum coils are vast and diverse, ranging from construction and automotive to electronics and food processing. The unique combination of durability, corrosion resistance, heat dissipation, and aesthetic appeal makes anodized aluminum coils a versatile material that finds use in numerous industries.

- Q: Is it possible to use aluminum coils as a material for crafting jewelry?

- <p>Yes, aluminum coils can be used to make jewelry. Aluminum is a lightweight, durable, and affordable metal that is often used in costume jewelry and art pieces. It's easy to work with, allowing for intricate designs and shapes. However, it's important to note that aluminum is not as valuable or as resistant to tarnishing as precious metals like gold or silver, so it may not be suitable for high-end or long-lasting jewelry pieces.</p>

- Q: Can aluminum coils be used in marine or saltwater environments?

- Indeed, marine or saltwater environments allow for the utilization of aluminum coils. The exceptional corrosion resistance of aluminum renders it a fitting material for a multitude of marine applications. The naturally occurring oxide layer on the exterior of aluminum acts as a shield against saltwater and other corrosive substances. This layer can be further fortified via procedures such as anodizing or painting, thereby augmenting its ability to resist corrosion. Furthermore, the lightweight nature of aluminum coils confers an advantage in marine applications where the reduction of weight is sought after. On the whole, the corrosion resistance and lightweight characteristics of aluminum coils render them a favored option in marine and saltwater environments.

- Q: I have a school project due in a couple weeks and I need to make a life size sculpture of a camera. I don't want to make it solid because that would use a lot of clay and wouldn't evenly cook. Can I put something inside like aluminum foil?

- I assume so, since it can go in ovens when you cook. I'd just make sure its in a relatively smooth shape, like folded until it forms a rectangle, before putting it in the clay.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a common material choice for evaporator coils in refrigeration systems due to its excellent heat transfer properties, corrosion resistance, and lightweight nature.

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- Aluminum Vs Carbon Fiber

- Q: Can aluminum coils be formed or shaped?

- Yes, aluminum coils can be formed or shaped.

- Q: The choice between Vinyl and Aluminum? By Mastercraft Exteriors

- Vinyl. Aluminum dents, and the paint can be scratched off. Vinyl pops back, and the color goes all the way through.

- Q: Can aluminum coils be used in the production of railway tracks?

- No, aluminum coils cannot be used in the production of railway tracks. Railway tracks are typically made of steel due to its strength, durability, and ability to withstand heavy loads and high temperatures. Aluminum, although lightweight, lacks the necessary strength and toughness required for railway track applications.

Send your message to us

Smooth Two Coat Finish Glossy RAL Color Coated Aluminum Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords