Fireclay Brick - SK34 Many Types of Refractory Fireclay Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

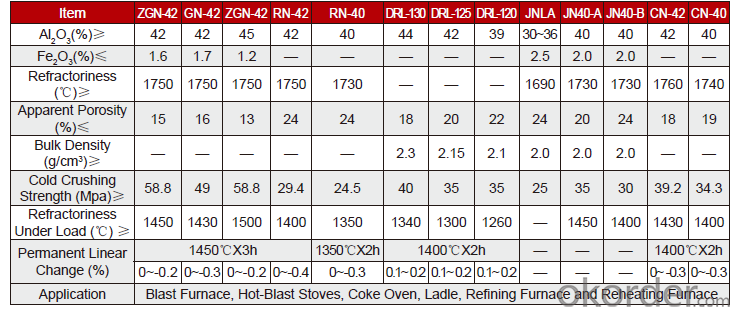

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Why is the house made of refractory bricks not warm in winter

- Heating equipment can be used

- Q: What are the differences between thermal?insulation?bricks and refractory bricks?

- Thermal insulation brick is thermal insulative; refractory brick is high temperature resistant.

- Q: Does circulating fluidized bed boiler's furnace wall use refractory to have thermal insulation?

- Now all use castable refractory, the outer layer is generally pouring refractory castable, the inside layer is a heat insulation castable refractory.

- Q: What are the main raw materials of refractory brick and runner brick?

- Types of refractory bricks are divided into low-grade and high-grade. generally, siliceous, semi siliceous and high aluminous runner brick brick have higher requirements. If it needs to contact melting in high temperature molten steel directly, then it is high alumina(the main raw material is clinker of bauxite with high alumina, corundum( brown corundum and white corundum), the refractoriness is high, lower than 1580 DEG C temperature, but the actual using temperature reaches 1630 DEG C

- Q: What are the advantages and disadvantages of clay refractory bricks?

- Clay refractory bricks are clay products with Al2O3 content of 30%~40% aluminum silicate material. Solid clay refractory bricks are one of the oldest building materials in the world. They are from the Mausoleum of the First Qin Emperor in Shaanxi to Beijing and the Ming and Qing Dynasties in the Great Wall. It has inherited the history of architectural civilization of the Chinese nation for thousands of years. So far, it is still a popular building material. Fireclay brick materials, cheap, durable, fireproof, heat insulation, sound insulation, also absorb moisture and other advantages, is widely used in civil engineering.

- Q: is there any requirement for radioactive materials in refractory materials.

- they all do not cause radiological hazards to the environment, so no requirements! analyze rom the element , magnesia. Do not know if it is useful, but material used by refractory materials, firstly any chemical elements are radioactive, human beings can not close, then, such as silicon dioxide: If it is radioactive. analyze from use, such as bauxite, does not have the use value

- Q: The difference between fireclay brick and refractory cilica brick in the application.

- Good thermal shock stability, long-term use temperature is not higher than 1300 degrees, high temperature, high strength, low price of clay brick characteristics, thermal shock stability is the worst, a scrap, can be long-term used under the condition of high temperature (exceed 1400 degrees Celsius) . The temperature of silica brick's soft bearing is close to the melting point. Other industries basically don't use, but the comprehensive performance of high temperature is not good, widely used in low temperature parts of a variety of furnaces. The silica brick is generally used in the coke oven and glass kiln, but anti alkali erosion ability is poor

- Q: What are the main constituents in non clay brick sintering?

- Sintered clay brick, it is through the mining soil, brick making, modulation, drying, roasting and cooling produced, roasting coal amount is solid sintered clay brick coal blending amount of 20-60%, the amount of coal to ensure product's surface.

- Q: cement concrete What kind of cement should be used to manufacture high temperature resistant Kang cement?

- Portland slag cement 325 or 425. Use phosphate cement or aluminate cement. Use portland cement. You can also use the fragment and power of waste refractory brick or fireclay brick or aluminous refractory brick.

- Q: What is the life of an old fashioned refractory brick kiln transformed into a flat topped tunnel kiln? what material should be used to transform the old fashioned refractory bricks vault kiln to flat tunnel kiln, and how long is the service life?

- 123

Send your message to us

Fireclay Brick - SK34 Many Types of Refractory Fireclay Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords