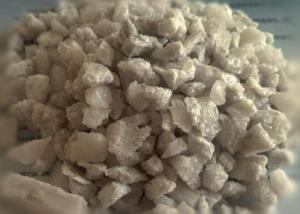

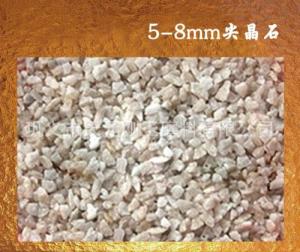

Raw Materials for Refractory:Sintered Spinel Al2O3 58-62 MgO 28-32

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

· Shape:particle or powder

· Material:Alumina

· Al2O3 Content (%): 58-62%

· Mgo Content (%): 28-32%

· Fe2O3:1.8%max

· SiO2Content (%): 2.7max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Sintered spinel

· Color:White or grey yellow

· Size:100MESH/200MESH/0-1MM/1-3MM/3-5MM/0-40MM or as customer's request

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:particle or powder or clinker

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: Does anyone know the characteristics of refractory for glass kiln?

- Quartzitic sandstone. Also known as quartzitic sandstone or white gravel. Which is a kind of natural refractory and quartz sandstone bonded by the kaolinite. Who appearance is better to be steel-grey, dense and hard, free of impurities and stripes. Its main crystalline phase is mainly quartz and kaolinite. Which has obvious stratified structure and anisotropism. The refractoriness fluctuation is between 1650~1730 ℃. The expansibility of quartzitic sandstone is different from that of silica?brick, who has maximum coefficient of thermal expansion under temperatures of 700 ~ 800 ℃, and it is most likely to burst at this time. The load softening temperature and the compression strength of calcined quartzitic sandstone have been improved significantly, with small residual expansion, stable volume, better thermal shock resistance, so it is generally to use calcinated quartzitic sandstone as refractories. which has been widely used as sidewall blocks on the small and medium sized furnaces.

- Q: How can refractory material of the electric furnace be used for longer.

- Key: 1, consider the furnace size; As furnace volume differs, pressure of liquid iron (steel) on the crucible wall lining will not the same; 2, consider melting steel type: If different steels are melt, the erosion of steel liquid on the lining refractory is not the same; 3, give full consideration to the lining of the grain size distribution of the refractory material, otherwise, it will cause of refractory matrix size segregation. 4, regardless of the kind of refractory materials, take full consideration into the mineral phrase of refractory material, high temperature and other equal factors. 2011 - 01 - 05 Guangyi mineral

- Q: Who can tell me what is neutral refractory?

- Refractories mainly refer to aluminum oxide, chromium oxide and carbon as the main component of refractory materials, such as corundum brick, high alumina brick, and carbon brick. Its characteristic goes to the resistance to both acidic and basic slag. Basic refractories mainly refer to the refractory materials whose mian components are magnesium oxide and calcium oxide, including magnesia bricks, magnesia-alumina bricks, magnesia chrome bricks, dolomite bricks, etc. Basic refractory is good at resisting basic slag erosion.

- Q: Refractory material, refractory brick

- High alumina brick is commonly used in high aluminum, LZ-75, LZ-65 and LZ-55, as well as high alumina brick for blast furnace, high alumina brick for hot blast furnace, and low creep high alumina brick

- Q: What are the applications of refractory in petroleum?

- Petroleum industrial furnace has many varieties. Generally, it includes tubular with complex structure, whose use temperature is generally 500 to 600 degrees centigrade, sometimes may be 800 degrees centigrade. Petroleum gas contains hydrogen sulfide and solid particulate matter; first correct the answer of the first floor: It is not used in petroleum industry. As shown in the left picture, it is tubular heating furnace, appilied to metallurgical industry. Lined with lightweight insulation and wear-resistant layers, and resistant to wear and corrosion: 1; & nbsp, but the using temperature is not high; it is a thermal equipment in the oil refining process. High alumina refractory castable used for refractory layer. It is an important equipment of petroleum boiling catalysis and dissociation. You can choose light refractory bricks or refractory?castables; as shown in the right picture, it is catalytic cracking unit, and can bear pressure. Note; & nbsp: // f; & nbsp.hiphotos, fire-resistant plastic or refractory ramming mass has chemical corrosion and wear effect on lining; & nbsp, less than 1,350 degrees centigrade. The yse temperatures is up to 1,100 degrees centigrade.

- Q: Concrete composition and function of magnesia bond used in refractory

- According to the chemical composition and use can be divided into metallurgical magnesia, magnesia brick, magnesia brick, magnesia brick, magnesia calcium brick, magnesia brick and other varieties. Its performance is greatly affected by CaO/SiO2 ratio and impurities. High purity magnesia brick refractoriness under load and thermal shock resistance are better than the general magnesia brick. High refractoriness, has good resistance to alkaline slag and iron slag, is a kind of important senior refractories. Use of magnesia product production by sintering process, sintering temperature is 1500 ~ 1800 DEG C, in addition, you can also add chemical bond, made of brick and unshaped refractory material. Mainly used in open hearth furnace, electric furnace, converter, oxidation non-ferrous metal smelting furnace, cement kiln and alkaline refractory kiln etc..

- Q: Who can tell me about the foundry refractory materials?

- Such as: neutral, alkalic, acidic refractories. Of course, the raw materials of different materials are not the same. Such as: the magnesia-carbon bricks, basic refractory materials: magnesite(electric?smelting, high-purity)+ crystalline flake graphite+ phenolic resin+ additive (aluminate or silicon powder or silicon carbide powder or high-temperature pitch) and so on.

- Q: Why does refractory need to add coarse firstly and then add fine aggregate?

- Adding coarse aggregate is to assure its good combination with fine aggregate. This is just the experience. You don't have to ask.

- Q: What refractories are resistant to fluorine gas?

- It is recommended to use fused-quartz brick, which will produce hydrofluoric acid fluorine (an acidic gas) when water vapors. It is cheap. While it is recommended to use silica?brick if it exceeds 1,200 degrees. So acidic refractory is an advisable refractory for using. It works well if the temperature is below 1200 degrees.

- Q: What kinds of fireproof materials does the safe use?

- Copper is one of the most widely used material in safe, for its good mechanical performance, corrosion resistance and processibility and it has beautiful color. Especially handles, locks and other decorations forged of copper are smooth, pore-free, also they have good density, and no blisters. They are solid and rust-proof, which can get gilded with 24K gold or gulch-gold and have other surface treatments. A lot of colors have been added to people's home for the copper's magnificence and nobleness.

Send your message to us

Raw Materials for Refractory:Sintered Spinel Al2O3 58-62 MgO 28-32

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords