Silicone Coated Fiberglass Scrim Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric Coated with Silicone Rubber

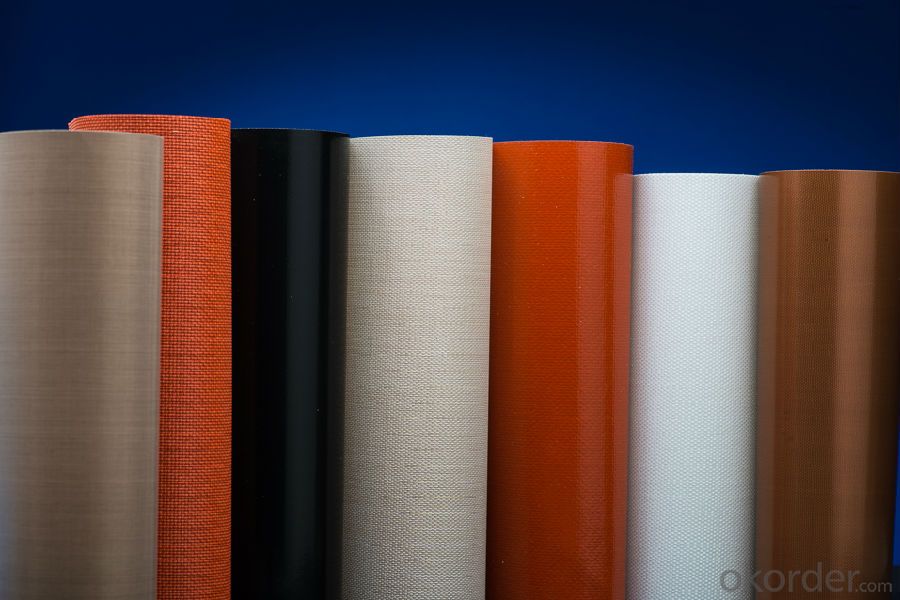

Fiberglass Fabric Description

Silicone coated fiberglass fabricare made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: How does fiberglass fabric perform in extreme temperatures in HVAC systems?

- Fiberglass fabric is well-suited for extreme temperatures in HVAC systems due to its excellent thermal resistance properties. It can withstand high temperatures without melting or deforming, making it a reliable choice for insulation and ductwork in such systems. Additionally, fiberglass fabric has a low coefficient of thermal expansion, meaning it will not expand or contract significantly with temperature changes, ensuring the integrity and efficiency of the HVAC system in extreme temperature conditions.

- Q: Are fiberglass fabrics suitable for use in the defense industry?

- Yes, fiberglass fabrics are suitable for use in the defense industry. They offer numerous advantages such as high strength, durability, and resistance to fire, chemicals, and extreme temperatures. These qualities make fiberglass fabrics ideal for applications such as ballistic protection, vehicle armor, and aircraft components, enhancing the safety and performance of defense equipment.

- Q: How is fiberglass fabric used in the production of composites?

- Industries such as aerospace, automotive, construction, and marine rely on fiberglass fabric as a critical component in the production of composites. Composites are materials formed by combining different components, with fiberglass fabric being a commonly used reinforcing material. During the production process, fiberglass fabric is typically mixed with a matrix material, like resin, to create a composite structure. The fabric itself consists of thin strands of glass fibers woven together to form a flexible and strong fabric. These glass fibers provide reinforcement and strength to the composite material, making it highly durable and resistant to external forces. One of the main advantages of using fiberglass fabric in composites is its excellent tensile strength. The woven fabric structure ensures even distribution of the load across the composite material, enabling it to withstand high levels of stress and prevent cracks or fractures. This property proves particularly beneficial in applications that require lightweight yet strong materials. Furthermore, fiberglass fabric exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures. This makes composites reinforced with fiberglass fabric suitable for use in harsh environments where traditional materials may fail. For instance, fiberglass composites are commonly employed in aircraft and boat construction due to their ability to withstand the corrosive effects of saltwater and harsh weather conditions. Fiberglass fabric is also highly versatile and can be tailored to meet specific requirements. Manufacturers can produce it in different thicknesses, weaves, and finishes, allowing customization to suit desired applications. Additionally, it can be combined with other reinforcing materials, like carbon fiber or kevlar, to create hybrid composites with unique properties. In conclusion, fiberglass fabric plays a vital role in the production of composites, providing strength, durability, and resistance to environmental factors. Its versatility and customizability make it a preferred choice for various industries in need of lightweight yet robust materials.

- Q: How is fiberglass fabric used in the marine industry?

- Fiberglass fabric is commonly used in the marine industry for its strength, durability, and resistance to corrosion. It is used in the construction of boats, yachts, and other watercraft to reinforce the hull, decks, and cabin structures. The fabric is often combined with resin to create a composite material that provides excellent structural integrity, making the vessels more lightweight and fuel-efficient. Additionally, fiberglass fabric is used to manufacture components like hatches, panels, and insulation, as it offers good thermal and sound insulation properties.

- Q: The thickness of the stone concrete protection layer on the waterproof layer shall not be less than mm.

- Fine stone concrete roofing waterproof layer on the protective layer thickness of not less than 40mm, the basement of fine stone concrete roof waterproofing layer on the protective layer thickness of not less than 70mm, the fine stone concrete basement floor of the protective layer thickness should be greater than 50mm.

- Q: How does fiberglass fabric compare to other insulation materials?

- Fiberglass fabric, when compared to other insulation materials, offers several advantages and disadvantages. One of the key advantages of fiberglass fabric is its superior thermal insulation properties. It has a low thermal conductivity, which means it effectively prevents heat transfer. This property makes it an excellent choice for both residential and commercial insulation needs, as it helps to retain heat during colder months and keeps spaces cool during hotter periods. Additionally, fiberglass fabric is known for its durability and longevity. It is resistant to moisture, fire, and chemicals, making it a reliable choice for insulation purposes. It does not degrade easily over time, ensuring that it maintains its effectiveness and insulation properties for many years. Another advantage of fiberglass fabric is its versatility and ease of installation. It is available in various forms, including rolls, batts, and loose-fill, making it suitable for different applications. It can be easily cut and shaped to fit any space, allowing for a seamless installation process. Moreover, it does not require any specialized tools or equipment for installation, making it a cost-effective option. However, fiberglass fabric does have a few drawbacks that should be considered. One of the main concerns is the potential health risks associated with handling fiberglass. The tiny glass fibers can become airborne during installation or if the fabric is damaged, which can lead to skin irritation, eye, and respiratory issues. Therefore, proper protective gear, such as gloves and masks, should be worn when working with fiberglass fabric. Furthermore, fiberglass fabric has a relatively lower sound insulation capability compared to some other materials. While it can provide some level of soundproofing, it may not be as effective in reducing noise transmission as specialized soundproofing materials like foam or cellulose insulation. In conclusion, fiberglass fabric offers excellent thermal insulation, durability, and ease of installation. However, it is important to be aware of the potential health risks and its limitations in terms of sound insulation. It is recommended to consult with professionals and consider specific requirements before choosing fiberglass fabric as an insulation material.

- Q: How does fiberglass fabric perform in high-temperature environments?

- Fiberglass fabric performs well in high-temperature environments due to its excellent heat resistance properties. It can withstand temperatures up to 1000°F (540°C) without significantly degrading or melting. This makes it a suitable material for various applications such as insulation, fireproofing, and protective clothing in industries where high temperatures are present.

- Q: Can fiberglass fabric be used for making automotive parts?

- Yes, fiberglass fabric can be used for making automotive parts. Fiberglass fabric is known for its strength, durability, and resistance to heat and chemicals, making it an ideal material for automotive applications. It can be used to create various automotive parts such as hoods, fenders, spoilers, and interior components like door panels. Fiberglass fabric can be easily molded into complex shapes, allowing for the production of customized automotive parts. Additionally, it is lightweight, which can help improve fuel efficiency and overall vehicle performance.

- Q: How does fiberglass fabric handle saltwater exposure?

- The resistance of fiberglass fabric to saltwater exposure is widely recognized. This is because the fabric is made up of glass fibers, which makes it highly resistant to the corrosive effects of saltwater. Unlike materials like steel or aluminum, fiberglass does not rust or corrode when it comes into contact with saltwater. Saltwater contains high levels of sodium chloride, which can be extremely harmful to many materials. However, fiberglass fabric remains unaffected by this corrosive element. This is because the glass fibers used in fiberglass are chemically inert and do not react with the salt in saltwater. As a result, the fabric maintains its structural integrity, strength, and durability even after prolonged exposure to saltwater. Furthermore, fiberglass fabric also has resistance to other elements commonly found in saltwater, such as seaweed, algae, and marine organisms. These elements often attach themselves to surfaces, causing damage or reducing performance. However, the smooth and non-porous surface of fiberglass fabric makes it challenging for these organisms to adhere. This reduces the need for maintenance and extends the lifespan of the fabric. In conclusion, fiberglass fabric is an excellent option for saltwater exposure due to its ability to resist corrosion and damage from saltwater, as well as its capacity to repel marine organisms. Whether it is used in marine applications like boat hulls, docks, or coastal structures, fiberglass fabric provides a durable and dependable solution for saltwater environments.

- Q: What are the different widths available for fiberglass fabric rolls?

- Fiberglass fabric rolls typically come in various widths to accommodate different applications and preferences. The available widths can vary depending on the manufacturer, but some common options include 1 inch, 2 inches, 3 inches, 4 inches, 6 inches, 12 inches, and 24 inches. These widths are designed to provide flexibility and versatility for a range of projects, from small repairs and patching to larger-scale applications such as boat construction or automotive repairs. It is important to check with the specific supplier or manufacturer to determine the exact widths available for fiberglass fabric rolls, as they may offer additional or customized options to cater to specific needs.

Send your message to us

Silicone Coated Fiberglass Scrim Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords