SG2 Carbon Steel Welding Wire ER70S-6

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SG2 Carbon Steel Welding Wire ER70S-6

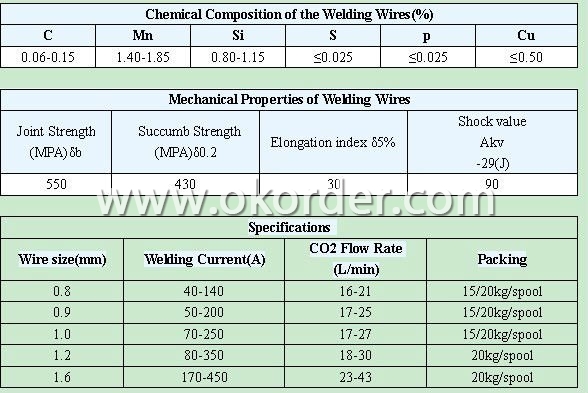

Material: copper coated carbon steel

Wire dia: 0.8/0.9/1.0/1.2/1.6mm

Packing: 15/20kgs/plastic spool/box, 72boxes/pallet

er70s-6 welding wire/ copper welding wire

1.Material:copper coated carbon steel

2.Wire diameter:0.8/0.9/1./1.2/1.6mm

3.Packing:15/20kgs/plastic spool/box, 72boxes/pallet.

4.Usage:

welding wire has excellent mechanical performance such as depositing speed and high efficiency, stable arc, little splash , good welding seam, strong resistance to surface scales and oil stains on the base metal, mainly used for welding low carbon alloy steel, industries of vehicles, bridge-engineering, machine-engineering, steel structures, shipping manufacture.

5.specification

- Q: Why is flux cored wire submerged arc welding?

- Relatively, the price of the submerged arc flux cored wire is lower, and it depends on what welder you choose. There are submerged arc welding machines and gas shielded welding machines. Therefore, there is submerged arc flux cored wire.

- Q: 711 flux cored wire can weld 16 manganese steel plate, No.

- Yes, no problem. It can be welded! Q345's handle

- Q: What wire is H08CrMoVA H13C rMoA what wire is it?

- The selection of different welding alloy steel welding in recent years are based not on the high - low, according to the above principles should be based on one side of the 12Cr1MoV selection of welding materials, 12Cr1MoV belongs to low alloy heat-resistant steel, the general selection of welding wire R31 welding, and the corresponding electrode for R317

- Q: What gas should be used in the use of stainless steel wire for nitrogen dioxide gas shielded welding?

- When using stainless steel wires, argon is used as a protective gas. You can also use a mixture of 95% argon and 5% carbon dioxide as a protective gas. Because the cooling effect of the welding torch is not good when using pure argon, the nozzle and nozzle are easy to red and burn. Add some carbon dioxide gas, will play a cooling effect.

- Q: Which kind of welding wire is needed for the welding of No. 20 steel and 316L?

- A302, A312, A062, A042, A102, A402, etc. can be used (manual arc welding)Suggest A042 or A402.A402 high temperature 1150 degreesGFS-309MOL (GB/T17853, E309MOT1-1) for carbon dioxideGTS-309MOL for argon arc welding

- Q: Two how many kinds of wire welding equipment are needed? How much do you charge for a set? Thank you.

- Two wire equipment needs pretreatment equipment, Mary eighth boron coated tank drawing machine, CNC precision pull straight wiredrawing machine, expansion of copper production line, winding machine can be produced; a set of 10 hours of production of 1.2 wire 3 tons of equipment prices in 550 thousand.

- Q: What welding wire for F22 valve steel and 12Cr1MoV pipe welding?

- The welding process is complex and needs to be evaluatedPreheat the whole or part of the weld before welding, guarantee the preheating temperature 250~300 degrees within the range of 150mm on both sides of weld, and the temperature between layers shall be within the control range of preheating temperature.GTAW (pure Ar gas protection): it is recommended to adopt TIG-R31 (including V) welding wire, diameter 2.5mm, current 100 ~ 140A.If there is a certain wall thickness, the pipe diameter is not very small, it is recommended to take GTAW+SMAW.SMAW: the welding rod adopts R337, and the specifications can be determined according to the actual situation.After welding, clean splash, heat up to 350~450 degrees, keep warm and cool after heat.12Cr1MoV best use of the corresponding components of heat-resistant steel electrode, such as R310, R312, R317, R316Fe, preheating 250~350 degrees before welding, welding tempering treatment 710~750 degrees.

- Q: Two welding machine, 1 of the welding wire into 1.2 of the need to change where?

- Replace the torch head with a matching pair. Do not change the other, or adjust the current properly.

- Q: Loose summer welding machine two, welding 0.8 wire current and voltage how to adjust?

- The welding parameters chungha Niho welding: welding wire diameter of 0.8 meters, voltage: 17V~19V, 90A~130A welding current and arc length 8 mm, gas flow rate 6L~12L minutes, left to the welding direction welding.According to the different welding parameters and welding position, according to the factors of parent material thickness, broken arc spot welding long weld welding specific selection of welding parameters.Panasonic two welding machine. No chungha Niho welding machine.

- Q: Is there any difference between stainless steel wire and stainless steel wire?

- I think the difference is great,

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia South Asia |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;ISO 17799 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | XINGANG |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

SG2 Carbon Steel Welding Wire ER70S-6

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords