Welding Wire AWS 5.18 ER70S-6 Copper Coated High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Welding Wire Descrition

Applicable for single pass and multi-pass welding of carbon steel and 500 MPa grade low alloy steel and is widely used in such fields as automobile industry, construction machinery manufacturing, ship building, metallurgical and mining equipment manufacturing, bridge building, petrochemical industry and pressure vessel manufacturing, etc. Also applicable for high-speed welding of sheets and pipeline steel.

CO2 gas-shielded copper-plated welding wire has excellent welding technological property: the electric arc is stable with less spattering, the appearance of welded joint is nice with good crack resistance: it applies to all-position welding.

2.Main Features of Welding Wire

1. stable arc

2. low splashing

3. high deposited effeciency

4. beautiful seam

5. suitable for all position

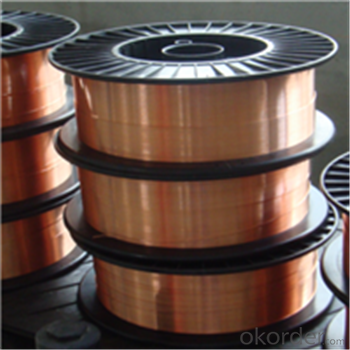

3.Welding Wire Images

4.Welding Wire Specification

ELEMENT | C | Mn | Si | P | S | Cu | |||||||||||

SPECIFICATION | 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.025 | ≤0.025 | ≤0.50 | |||||||||||

ACTUAL RESULT | 0.099 | 1.54 | 0.92 | 0.015 | 0.011 | 0.03 | |||||||||||

MECHNICAL PROPERTIES OF THE ALL-WELD-METAL | Shielding Gas or Flux | Radiographic Test | |||||||||||||||

ITEM | (Mpa) TENSILE | (Mpa) YIELD STRENGTH | (%)ELONGATION | TEST OF V MODLE IMPACT | |||||||||||||

IMPACT VALUE | TEST TEMP | ||||||||||||||||

SPECIPHICATION | ≥500 | ≥420 | ≥22 | ≥27J | -20°C | CO2 | Ⅱ | ||||||||||

ACTAUL RESULT | 542 | 437 | 29.3 | 79 83 81 | -20°C | CO2 | Ⅰ | ||||||||||

5.FAQ

Q:Are you factory?

A:Yes, we are factory not shell company. So we can promise good prices and best quality. Welcome you to visit our factory.

Q: What's the delivery time?

A: For products in stock, we can ship it within 7 days after receiving your payment. For custom order, within 24 tons, production time is 20-30 days after confirmed every details.

Q: What about the warranty?

A:Best price offer,On-time delivery,Strict quality control,The most comprehensive and the most attentive service

- Q: What welding wire should be used when welding between 0cr18Ni9 and 0cr18Ni9?

- Base metal 0Cr18Ni9, welding rod A137, argon arc welding wire H0Cr20Ni10.1, welding wire is used as filler metal or as a conductive wire welding material.2, in gas welding and gas tungsten arc welding, welding wire used as filler metal; in submerged arc welding, electroslag welding and MIG arc welding, welding wire as filler metal, and conductive electrode. The surface of the wire is not coated with anti oxidizing flux.

- Q: The design pressure is 27.5Mpa and the hydraulic test pressure is 41.25Mpa. Can the ER304 welding wire reach the strength requirement?In addition, what welding wire is used in the welding argon arc welding between 20# steel tubes? Given a better buy on the market, piping design pressure of 4.0Mpa.

- Base metal 0Cr18Ni9 welding rod A137 argon arc welding wire H0Cr20Ni10Base material 20 welding rod E4303 welding wire TIG-J50High pressure pipeline, must do welding assessment, welder welding process according to the welding, pipeline group, the gap, etc. must strictly check, welding rod must bake, insulation

- Q: 3003 what welding wire used for aluminum welding, I have tried ER4047, but the aluminum plate has melted, the welding wire has not melted, I used 4MM welding wire. And you said to me is not the aluminum welding wire or other reasons, I should use what types of aluminum wire

- It's not a wire problem. Is it argon arc welding or?

- Q: What kind of welding material is TG-S2CW and what material is it?

- Wear resistant welding electrode, cobalt base welding electrode, mould welding electrode, nickel base welding rod, stainless steel welding rod, pipeline welding electrode, imported welding rod, imported welding wire, carbon steel welding rod, valve welding rod, surfacing welding electrode, nickel base welding wire, heat-resisting steel welding rodTIG welding material for 2.25%Cr-W-Nb-V steel

- Q: What kind of wire is ER80S-G and what material is it mainly welded to?

- Carbon steel or low-alloy steel of 550MPa strength

- Q: What is the relation between Jing Lei welding wire and Beijing group welding wire?

- Jing Lei Shijing group welding company's trademark.So,"Jing Lei" is a trademark nameBeijing group is the name of the company.

- Q: Loose summer welding machine two, welding 0.8 wire current and voltage how to adjust?

- The welding parameters chungha Niho welding: welding wire diameter of 0.8 meters, voltage: 17V~19V, 90A~130A welding current and arc length 8 mm, gas flow rate 6L~12L minutes, left to the welding direction welding.According to the different welding parameters and welding position, according to the factors of parent material thickness, broken arc spot welding long weld welding specific selection of welding parameters.Panasonic two welding machine. No chungha Niho welding machine.

- Q: Who knows the C02 gas shielded welding gas and wire consumption ratio?Who knows the C02 gas shielded welding gas and wire consumption ratio?No problem.

- Depending on how you solder it, use a bottle of gas a day

- Q: What gas will be produced when welding with wire and argon?

- Argon arc welding wire without coating, no metal powder, logically speaking, exhaust only water vapor and carbon dioxide, but the steel and welding materials are not one hundred percent pure, no matter how smelting are containing impurities. The temperature of the arc is very high, 9000-10000K, so some parent materials and many impurities are volatilized by steam.

- Q: How many meters is one kilogram of stainless steel wire 2?

- Say, model, know the ingredients, calculate the density, then count the length, say what brand

Send your message to us

Welding Wire AWS 5.18 ER70S-6 Copper Coated High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords