Schedule 40 Seamless Carbon Steel Pipe A335P95 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

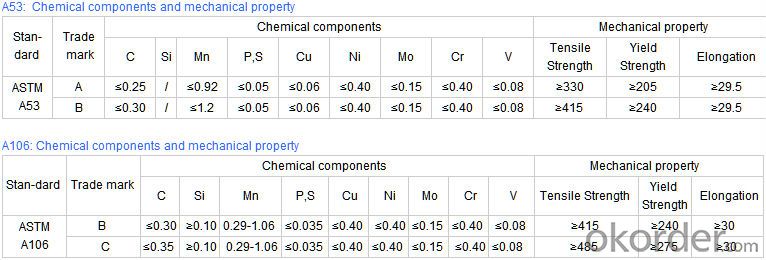

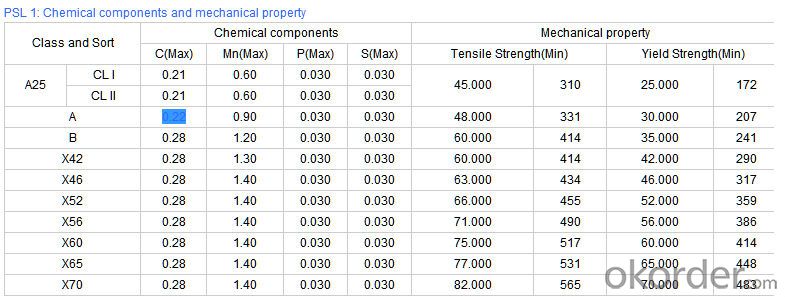

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: Seamed steel pipe seamless steel pipe, carbon steel pipe, galvanized pipe, four how to distinguish between

- Seamless steel tube processing technology:1.1 、 hot rolled seamless tubes are usually produced on automatic rolling mills. After checking and cleaning the surface defects, the solid tube is cut into the required length, centring on the end face of the tube blank, then sent to the heating furnace and punched on the piercer. At the same time, the hole rotates and advances continuously. Under the action of the roller and the plug, the inner cavity of the pipe blank is gradually formed, and the cavity is called the capillary. Sent to the automatic tube rolling mill on rolling. Finally, the thickness of the whole machine is the same, and the diameter of the sizing machine is determined to meet the specifications. It is an advanced method to produce seamless steel tube by continuous rolling mill.1.2, in order to obtain smaller size and better quality of seamless tube, cold rolling, cold drawing method must be used or combined. Cold rolling is usually carried out on a two roller mill, where the steel tube is rolled in the annular groove made of variable cross section, round hole groove and stationary conical head. Cold drawing is usually performed in single chain or double chain cold drawn machines from 0.5 to 100T.1.3, the extrusion method will soon heat the tube blank in the closed extrusion cylinder, the perforation bar and extrusion rod movement, so that extrusion parts from the smaller hole extrusion. This method can produce smaller diameter steel pipe.Seamless steel pipe use: mainly used to transport fluid pipeline or structural parts.The main use of steel pipe joints (steel) two welded together, so the price is cheap, widely used.

- Q: How are steel pipes used in the agricultural irrigation systems?

- Due to their strength and durability, steel pipes are widely used in agricultural irrigation systems. These pipes effectively transport water from a well or reservoir to the fields where crops are cultivated. One major advantage of using steel pipes in such systems is their ability to withstand high pressure and heavy loads, making them suitable for the transportation of large volumes of water over long distances without the risk of bursting or breaking. Additionally, steel pipes exhibit a high resistance to corrosion, which is crucial in agricultural settings where they may come into contact with fertilizers or other chemicals. Aside from their durability, steel pipes offer a smooth interior surface that minimizes friction and ensures a consistent water flow. This is essential in irrigation systems as it guarantees even water distribution across the fields, promoting optimal crop growth. Moreover, steel pipes can be easily connected and configured to meet the specific layout and requirements of the irrigation system. In summary, steel pipes play a crucial role in agricultural irrigation systems by facilitating the efficient and reliable transportation of water to crops. Their strength, durability, resistance to corrosion, and smooth interior surface make them an ideal choice for these applications.

- Q: Can steel pipes be used for telecommunications cables?

- No, steel pipes cannot be used for telecommunications cables. Telecommunications cables are typically made of fiber optic or copper materials. Steel pipes are used for various applications in construction and plumbing, but they are not suitable for transmitting data or electrical signals. Fiber optic cables are designed to carry high-speed data over long distances, while copper cables are used for transmitting both data and electrical signals. These cables have specific insulation and shielding properties that steel pipes do not possess, making them unsuitable for telecommunications purposes.

- Q: What is the maximum allowable deflection for steel pipes?

- The maximum allowable deflection for steel pipes is typically determined by industry standards and design codes. These standards and codes specify the acceptable limits of deflection to ensure the structural integrity and functionality of the pipes. The maximum allowable deflection varies depending on various factors such as the pipe diameter, wall thickness, material properties, and the type of application. It is important to consult the relevant standards and codes, such as the American Society of Mechanical Engineers (ASME) B31.3 code for process piping or the American Water Works Association (AWWA) standards for water transmission and distribution pipes, to determine the specific maximum allowable deflection for a particular steel pipe application. Following these guidelines helps to ensure the safe and efficient operation of steel pipes in various industries and applications.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel is known for its durability, strength, and resistance to extreme conditions, making it suitable for various applications. Whether it is transporting liquids or gases in high-pressure systems or low-pressure systems, steel pipes can efficiently handle the demands of both.

- Q: How are steel pipes used in the construction of dams?

- Steel pipes are commonly used in the construction of dams for various purposes such as water diversion, drainage, and foundation reinforcement. They are used to transport water from one area to another, diverting it away from the construction site or controlling its flow within the dam. Steel pipes are also employed for drainage systems to prevent water accumulation and to ensure the stability of the dam structure. Additionally, they play a crucial role in reinforcing the foundation of the dam, providing strength and support to the overall structure.

- Q: Can steel pipes be used for underground compressed air pipelines?

- Indeed, underground compressed air pipelines can utilize steel pipes. The strength and durability of steel pipes make them a popular choice for subterranean pipelines. They possess the capacity to endure high pressure and withstand corrosion and other environmental elements. Moreover, steel pipes are renowned for their extended lifespan, rendering them a dependable option for compressed air pipelines. Nevertheless, it is crucial to guarantee the adequate coating and protection of the steel pipes to avert any potential corrosion concerns. Furthermore, the proper installation and maintenance of these pipelines are vital to ensure their efficiency and safety.

- Q: How do steel pipes handle water hammer in high-rise buildings?

- Steel pipes in high-rise buildings handle water hammer by absorbing the sudden pressure surges caused by the rapid opening and closing of valves. The strong and durable nature of steel pipes allows them to withstand the impact of water hammer without experiencing significant damage or ruptures. Additionally, the flexibility of steel pipes helps to dissipate the kinetic energy generated by the water hammer, reducing the risk of pipe bursts and ensuring the smooth flow of water throughout the building.

- Q: What are the uses of seamless steel tubes?

- A large number of pipes used for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

- Q: What are the different pressure ratings for steel pipes?

- The different pressure ratings for steel pipes can vary depending on factors such as pipe size, wall thickness, and the type of steel used. Common pressure ratings for steel pipes range from 150 psi (pounds per square inch) to 2500 psi or higher.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe A335P95 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords