All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of steel pipes in the healthcare industry for medical gas supply and distribution systems?

Steel pipes play a crucial role in the healthcare industry for medical gas supply and distribution systems. They are used to transport various medical gases, such as oxygen, nitrogen, and carbon dioxide, throughout healthcare facilities. Steel pipes are preferred due to their durability, resistance to corrosion, and ability to withstand high pressure. They ensure a safe and reliable supply of medical gases, which are essential for operating rooms, intensive care units, and other healthcare settings.

What measures can be taken to prevent steel pipes from corroding in acidic industrial environments?

There are several measures that can be taken to prevent steel pipes from corroding in acidic industrial environments. One effective measure is to apply protective coatings on the pipes, such as epoxy or polyethylene coatings, which act as a barrier against the corrosive acids. Additionally, using corrosion-resistant alloys, such as stainless steel or nickel alloys, for the construction of the pipes can greatly reduce corrosion. Regular maintenance and inspection of the pipes, including cleaning and removing any accumulated rust or corrosion, is also essential in preventing further damage. Finally, controlling the pH levels and acidity of the industrial environment through proper chemical treatment or neutralization can help minimize the corrosive effects on the steel pipes.

What are the environmental considerations when disposing of old or damaged steel pipes?

When disposing of old or damaged steel pipes, there are several environmental considerations to take into account. Firstly, steel is a recyclable material, so it is important to explore options for recycling the pipes rather than sending them to a landfill. Recycling helps conserve natural resources and reduces the carbon footprint associated with manufacturing new steel.

Another aspect to consider is the presence of any hazardous substances on or within the pipes. Steel pipes used in various industries, such as oil and gas, may have been exposed to chemicals or contaminants. Proper testing and evaluation should be conducted to determine if any remediation or specialized disposal methods are required to prevent environmental contamination.

Additionally, the transport and storage of the pipes during disposal should be carried out in a way that minimizes potential risks to the environment. This may involve ensuring that the pipes are securely contained and not at risk of releasing any substances during transportation or storage.

Lastly, local regulations and guidelines should be followed to ensure compliance with environmental laws and standards. These regulations may vary depending on the specific location, so it is essential to consult with relevant authorities or waste management agencies to determine the appropriate disposal methods for old or damaged steel pipes in a way that prioritizes environmental protection.

What is the impact of temperature on steel pipe performance?

The impact of temperature on steel pipe performance is significant. Steel pipes can experience changes in their mechanical properties, such as strength and ductility, when subjected to different temperatures. Extreme heat can cause the steel to soften, leading to a loss of strength and increased susceptibility to deformation or failure. Conversely, extremely low temperatures can make the steel brittle and prone to cracking or fracture. It is crucial to consider the operating temperature range when designing and using steel pipes to ensure their structural integrity and reliable performance.

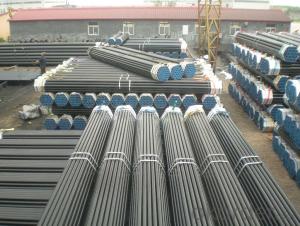

Wholesale Steel Pipes from supplier in Gabon

With our vast experience in the industry, we understand the specific requirements and challenges of the Gabonese market. We offer a wide range of steel pipes, including seamless and welded pipes, in various sizes, grades, and specifications to meet your project needs.

Our team of experts is dedicated to providing excellent customer service and technical support. We can assist you in selecting the right steel pipes for your applications, provide detailed quotations, and ensure timely delivery to your project site in Gabon.

As a subsidiary of CNBM, a renowned Fortune Global 500 company, we have the resources and capabilities to handle large-scale projects and meet your procurement demands. We adhere to strict quality standards and have established strong relationships with reputable manufacturers to ensure that our steel pipes meet international quality requirements.

Whether you are involved in infrastructure development, construction, oil and gas, or any other industry requiring steel pipes, we are your trusted partner in Gabon. Contact us today to discuss your steel pipe requirements, and let us provide you with top-quality products and exceptional service.

Our team of experts is dedicated to providing excellent customer service and technical support. We can assist you in selecting the right steel pipes for your applications, provide detailed quotations, and ensure timely delivery to your project site in Gabon.

As a subsidiary of CNBM, a renowned Fortune Global 500 company, we have the resources and capabilities to handle large-scale projects and meet your procurement demands. We adhere to strict quality standards and have established strong relationships with reputable manufacturers to ensure that our steel pipes meet international quality requirements.

Whether you are involved in infrastructure development, construction, oil and gas, or any other industry requiring steel pipes, we are your trusted partner in Gabon. Contact us today to discuss your steel pipe requirements, and let us provide you with top-quality products and exceptional service.