Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

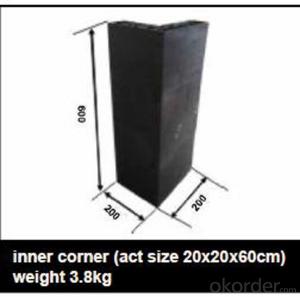

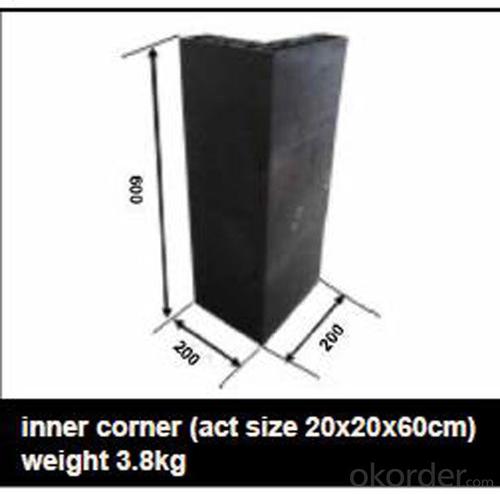

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Q: Are there any specific requirements for bracing steel frame formwork?

- Yes, there are specific requirements for bracing steel frame formwork. The bracing system must be designed and installed to ensure the stability and safety of the formwork during construction. It should be able to resist lateral and vertical forces, including wind loads and concrete pressure. The bracing should be properly spaced, secured, and aligned to prevent any deformation or failure of the formwork. Additionally, the bracing system should be regularly inspected and maintained to ensure its effectiveness throughout the construction process.

- Q: Can steel frame formwork be used for both heavy and lightweight concrete structures?

- Yes, steel frame formwork can be used for both heavy and lightweight concrete structures. Steel frame formwork is a versatile and durable solution that can accommodate different types of concrete structures. It provides the necessary support and stability during the pouring and curing process, regardless of the weight of the concrete. The strength and rigidity of steel make it suitable for heavy concrete structures, while its flexibility and adaptability allow it to be used for lightweight concrete structures as well. Additionally, steel frame formwork can be easily adjusted and reused, making it a cost-effective option for various construction projects.

- Q: Can steel frame formwork be used in projects with limited availability of skilled labor?

- Projects with a shortage of skilled labor can utilize steel frame formwork. This construction method offers various benefits, including ease of use, durability, and accuracy. It requires minimal training and expertise, making it suitable for projects with limited skilled labor. Steel frame formwork systems are designed to be easy to use and adaptable to different project requirements. They come with detailed instructions, enabling less skilled workers to assemble and disassemble the formwork efficiently. This reduces the need for highly skilled labor and saves time and costs in training or hiring specialized workers. Additionally, steel frame formwork is known for its strength and longevity. The frames are made of high-quality steel, ensuring stability and durability. Once properly installed, the formwork can withstand the pressures and forces of concrete pouring, resulting in consistent and high-quality finishes. In conclusion, steel frame formwork is a suitable option for projects with limited skilled labor. Its user-friendly design and durability make it an efficient and cost-effective solution, allowing less skilled workers to effectively carry out formwork tasks.

- Q: Can steel frame formwork be used in projects with limited construction site access to construction vehicles or equipment?

- Projects with limited construction site access to construction vehicles or equipment can utilize steel frame formwork. This versatile and durable system does not require extensive equipment or vehicles for installation. Its lightweight characteristics allow for easy assembly and dismantling on-site, without the need for heavy machinery. The steel frame formwork system can be transported in smaller sections or panels, making it suitable for construction sites with limited access. These panels can be carried by hand or transported using smaller, more maneuverable vehicles such as pickup trucks or trailers, which are better suited for restricted spaces. Moreover, steel frame formwork is a practical choice for projects where traditional formwork methods may prove impractical due to limited access. Its modular design provides flexibility and adaptability, allowing it to accommodate various construction site conditions. To conclude, steel frame formwork is a viable option for projects that face limited access to construction vehicles or equipment. Its lightweight nature, ease of assembly, and adaptability make it a feasible solution for such scenarios.

- Q: How does steel frame formwork handle different types of reinforcement?

- The versatility and efficiency of the steel frame formwork system enable it to easily handle diverse types of reinforcement in construction projects. The main advantage of this system lies in its flexibility, which allows for seamless integration of various reinforcement materials, such as steel bars or mesh, without compromising the structural integrity of the formwork. The design of the steel frame formwork system caters to the weight and pressure exerted by the reinforcement materials, providing a robust and stable platform for their placement and installation. This ensures that the reinforcement stays in the desired position throughout the construction process. Additionally, the formwork system allows for convenient adjustment and modification to accommodate different reinforcement configurations. The steel frames can be easily adapted to the required shape and size, allowing for the inclusion of vertical or horizontal bars, as well as various reinforcement spacings. Furthermore, the steel frame formwork system boasts exceptional durability and strength, which are vital for handling diverse types of reinforcement. It can withstand the considerable loads and pressures encountered during concrete pouring and curing, guaranteeing the secure placement of the reinforcement. Overall, the steel frame formwork system is an excellent choice for contractors and engineers who aim to efficiently and effectively incorporate different reinforcement configurations into their construction projects. Its flexibility, adaptability, and strength make it an ideal option for such endeavors.

- Q: Can steel frame formwork be used for both single-storey and multi-storey construction?

- Yes, steel frame formwork can be used for both single-storey and multi-storey construction. Steel frame formwork is a versatile and durable system that can be easily assembled and disassembled, making it suitable for various construction projects. Whether it is a single-storey building or a multi-storey structure, the steel frame formwork can provide the necessary support and stability required during the concrete pouring and curing process. The steel frames can be adjusted and modified to accommodate different floor heights and layouts, allowing for flexibility in construction design. Additionally, steel frame formwork offers high load-bearing capacity, ensuring the structural integrity of both single-storey and multi-storey buildings.

- Q: How does steel frame formwork contribute to better concrete curing in different weather conditions?

- Steel frame formwork contributes to better concrete curing in different weather conditions in several ways. Firstly, the steel frame provides stability and support to the formwork, ensuring that it remains intact and in place during adverse weather conditions such as heavy rain or strong winds. This prevents any potential damage or collapse of the formwork, ensuring the concrete is not exposed to the elements prematurely. Secondly, the steel frame formwork provides a barrier against moisture and temperature fluctuations, which are crucial factors in proper concrete curing. It helps to retain the moisture within the concrete, preventing excessive evaporation, especially in hot and dry weather conditions. This allows for a slower and more controlled curing process, reducing the risk of cracking or shrinkage. Additionally, the steel frame formwork allows for efficient insulation, which is beneficial in extreme weather conditions. It helps to maintain a stable temperature within the concrete, protecting it from freezing or overheating, which can adversely affect the curing process. Overall, the use of steel frame formwork provides a reliable and durable system that ensures proper concrete curing, regardless of the weather conditions. It helps to create a controlled environment for curing, resulting in stronger, more durable concrete structures.

- Q: How does steel frame formwork differ from other types of formwork?

- There are several notable distinctions between steel frame formwork and other formwork varieties. To begin, steel frame formwork is composed entirely of steel, rendering it exceptionally robust and long-lasting. It can endure substantial loads without warping or bending, making it ideal for construction endeavors necessitating considerable strength and stability. Moreover, steel frame formwork boasts exceptional adaptability. It can be easily customized and adjusted to accommodate structures of various shapes and sizes. This flexibility permits the creation of intricate and distinctive designs that would be otherwise unattainable with alternative formwork options. Furthermore, steel frame formwork guarantees superior stability and precision. The steel frames offer excellent support, ensuring that the formwork remains securely in place throughout the concrete pouring and curing process. This results in superior construction quality and heightened accuracy. Additionally, steel frame formwork enjoys a lengthier lifespan compared to other formwork alternatives. Its durability and resistance to wear and tear enable its repeated use, rendering it an economically advantageous choice in the long term. Lastly, steel frame formwork can be assembled and disassembled relatively swiftly and effortlessly. The steel frames can be conveniently transported and put together on-site, saving time and labor expenses. This efficacy proves particularly beneficial for projects with tight time constraints or limited resources. In conclusion, steel frame formwork distinguishes itself from other formwork options due to its strength, versatility, stability, durability, and user-friendliness. These qualities make it an exceptional selection for construction ventures necessitating exemplary performance and efficiency.

- Q: Can steel frame formwork be easily integrated with other construction systems?

- Steel frame formwork offers effortless integration with other construction systems. This versatile and flexible system can be tailored to meet the specific needs of any construction project. It seamlessly combines with scaffolding, slab formwork, and wall formwork, among other systems. The modular design of steel frame formwork enables effortless assembly and disassembly, allowing for compatibility with different construction methodologies. Additionally, it easily adjusts and adapts to accommodate design or construction process changes, ensuring smooth integration with other systems. With its exceptional flexibility and compatibility, steel frame formwork is the perfect choice for integrating with diverse construction systems.

- Q: How does steel frame formwork handle different types of formwork stripping equipment?

- Steel frame formwork is a versatile and durable system that can handle different types of formwork stripping equipment with ease. The steel frames, which are designed to provide stability and support, can accommodate various stripping tools such as mechanical or hydraulic systems. One of the advantages of steel frame formwork is its ability to withstand the high pressure and force exerted during the stripping process. This is crucial when different types of stripping equipment are used, as they require a strong and sturdy support system to ensure safe and efficient formwork removal. The steel frames are engineered to provide a stable and secure platform for the stripping equipment. They are designed with precision and accuracy to ensure proper alignment and compatibility with different types of stripping tools. This ensures that the stripping equipment can be securely attached to the steel frame formwork, allowing for effective and efficient formwork removal. Furthermore, steel frame formwork is highly adaptable, making it suitable for use with various types of formwork stripping equipment. Whether it is a mechanical stripping system that relies on mechanical force or a hydraulic system that utilizes hydraulic power, the steel frames can accommodate and work seamlessly with these different types of equipment. In conclusion, steel frame formwork is specifically designed to handle different types of formwork stripping equipment. Its strength, stability, and adaptability make it an ideal choice for construction projects that require efficient and safe formwork removal.

Send your message to us

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords