Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

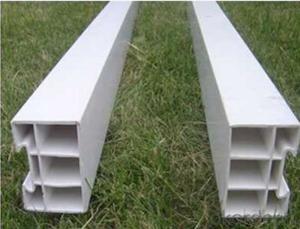

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

(4) Formwork System Scaffolding & Accessories:

Light Duty Shoring prop and Heavy Duty Shoring Prop; Wing nuts and Tie rods; RASTO clamp and so on.

FAQ Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: Can steel frame formwork be used for the construction of retail buildings?

- Yes, steel frame formwork can be used for the construction of retail buildings. Steel frame formwork provides a strong and durable structure that can withstand the weight and load requirements of retail buildings. Additionally, steel frame formwork allows for flexibility in design and can be easily adjusted to accommodate different layouts and store configurations.

- Q: How does steel frame formwork affect the overall project timeline?

- Steel frame formwork can have a significant impact on the overall project timeline. Firstly, steel frame formwork is generally quicker to assemble and disassemble compared to traditional timber formwork. This means that the formwork can be set up and removed more efficiently, thereby reducing the time required for each concrete pour. Additionally, steel frame formwork allows for higher repetition rates, meaning that the same formwork can be easily reused for multiple pours. This eliminates the need for constant construction and dismantling of formwork, leading to further time savings. Furthermore, steel frame formwork provides greater stability and durability compared to timber formwork. This stability allows for faster and more efficient concrete pouring, reducing the time required for each floor or section of the project. Moreover, steel frame formwork can be pre-fabricated off-site, allowing for concurrent construction activities. This means that while the formwork is being assembled on-site, other tasks such as earthworks or foundation construction can be carried out simultaneously, optimizing the project timeline. Overall, steel frame formwork offers numerous advantages that significantly impact the project timeline by reducing assembly and disassembly time, allowing for higher repetition rates, providing stability for faster concrete pouring, and enabling concurrent construction activities. These benefits ultimately result in shorter construction schedules and timely project completion.

- Q: How does steel frame formwork handle the placement of stairs and escalators within the concrete structure?

- A versatile and flexible system, steel frame formwork effectively handles the placement of stairs and escalators in concrete structures. When constructing stairs, steel frame formwork provides reliable support. The steel frames easily adjust to desired dimensions and designs, allowing for various types of staircases such as straight flights, spiral stairs, or curved designs. This flexibility promotes creativity in architectural designs and ensures seamless integration into the overall structure. For escalators, steel frame formwork offers necessary strength and stability. It can be designed to match escalator dimensions and configurations, providing a secure framework for installation. The engineered steel frames withstand dynamic forces and vibrations associated with escalator operations, ensuring long-term durability and safety. Additionally, steel frame formwork allows for efficient and speedy construction of stairs and escalators in concrete structures. Prefabricated steel frames are easily assembled and adjusted on-site, reducing construction time and labor costs. The modular system enables quick dismantling and reassembly, ideal for projects requiring frequent changes or modifications in stair and escalator positioning. Overall, steel frame formwork is the preferred choice for architects, contractors, and engineers in constructing buildings with stairs and escalators. Its flexibility, strength, and efficiency make it an ideal solution for incorporating these vertical transportation systems.

- Q: What are the safety measures that need to be taken while using steel frame formwork?

- When using steel frame formwork, there are several important safety measures that need to be taken to ensure the well-being of workers and the overall success of the construction project. These safety measures include: 1. Proper training and supervision: Workers should receive adequate training on the correct usage of steel frame formwork, including how to assemble, dismantle, and handle the equipment safely. They should also be supervised by experienced personnel to prevent any potential accidents. 2. Inspection and maintenance: Regular inspection of the steel frame formwork should be conducted to identify any defects, damages, or wear and tear. Any faulty or damaged components should be immediately replaced or repaired. Maintenance should also be carried out to keep the equipment in optimal condition. 3. Personal protective equipment (PPE): Workers should be equipped with appropriate PPE, such as safety helmets, safety goggles, gloves, and steel-toe boots, to protect themselves from potential hazards, such as falling objects or injuries during assembly and dismantling. 4. Secure footing and fall protection: Workers should have a secure footing when working on steel frame formwork structures. Proper scaffolding or platforms should be provided, and guardrails should be installed to prevent falls from heights. Additionally, safety harnesses and lanyards should be used when working at elevated levels. 5. Proper lifting techniques: Workers should be trained on proper lifting techniques to prevent strains or other musculoskeletal injuries when handling heavy components of the steel frame formwork. Mechanical aids, such as cranes or hoists, should be used whenever possible to minimize manual lifting. 6. Adequate lighting and ventilation: The work area should be well-lit to ensure good visibility, and proper ventilation should be provided to prevent the accumulation of harmful fumes or gases. 7. Communication and coordination: Effective communication and coordination between workers and supervisors are essential to ensure smooth operations and avoid accidents. Clear instructions, signals, and warning signs should be used to alert workers of any potential hazards or changes in the work environment. By following these safety measures, the risk of accidents and injuries can be greatly minimized when using steel frame formwork, creating a safer working environment for all involved.

- Q: Are there any specific considerations for using steel frame formwork in coastal areas?

- Yes, there are several specific considerations that need to be taken into account when using steel frame formwork in coastal areas: 1. Corrosion resistance: Coastal areas are prone to high levels of humidity, saltwater exposure, and corrosive environments. Therefore, it is crucial to use steel frames that have high corrosion resistance, such as galvanized or stainless steel. This will ensure the longevity and durability of the formwork system. 2. Material selection: The choice of materials for formwork should be carefully considered for coastal areas. It is important to select materials that can withstand the harsh coastal environment, including saltwater, wind, and sand. Steel frames are a suitable choice due to their strength and resistance to corrosion. 3. Maintenance: Regular maintenance is essential to prevent corrosion and ensure the longevity of steel frame formwork in coastal areas. This includes routine inspections, cleaning, and reapplication of protective coatings as necessary. Proper maintenance will help to extend the lifespan of the formwork system and prevent any potential safety hazards. 4. Anchoring and stability: Coastal areas often experience strong winds and storms, which can put additional loads and stresses on the formwork system. It is crucial to ensure that the steel frames are properly anchored and secured to withstand these forces. Additionally, the formwork system should be designed to have adequate stability and resistance against lateral loads, such as wind or wave action. 5. Environmental considerations: Coastal areas are often environmentally sensitive, with ecosystems that need to be protected. When using steel frame formwork, it is important to consider the impact on the surrounding environment. Measures should be taken to prevent any potential pollution or contamination during the construction process, such as using environmentally friendly coatings or sealants. Overall, while steel frame formwork can be used in coastal areas, it is essential to consider the specific challenges posed by the coastal environment. By selecting the right materials, implementing proper maintenance practices, ensuring stability and anchoring, and considering environmental factors, steel frame formwork can be effectively used in coastal construction projects.

- Q: A simple summaryThank you

- 11, composite plastic building template12, the structure of the combined structure of the template13, tempered glass combination template14, reinforced concrete component forming combination template15, steel frame plywood formwork16, the construction of light body template17, chemical building template production process and chemical formula18, the use of the heat preservation of the wet form

- Q: Can steel frame formwork be used for the construction of educational facilities?

- Yes, the use of steel frame formwork is applicable for the construction of educational facilities. Steel frame formwork is a versatile and durable system that offers robust support for concrete during the construction process. Its strength and stability make it suitable for the construction of a wide range of buildings, including educational facilities. One of the main advantages of steel frame formwork is its capacity to endure heavy loads and ensure a secure working environment. This is particularly crucial for educational facilities, which often accommodate a large number of individuals and necessitate sturdy and long-lasting structures to guarantee the safety of both students and staff. Moreover, steel frame formwork facilitates flexibility in design and construction. It can be easily adjusted and tailored to meet the specific requirements of educational facilities, such as the arrangement of classrooms, laboratories, and other specialized areas. This flexibility empowers architects and engineers to create practical and efficient spaces that cater to the needs of both students and educators. Furthermore, steel frame formwork is highly reusable and cost-effective. It can be disassembled and utilized multiple times for various construction projects, thus minimizing waste and conserving resources. This makes it an environmentally friendly choice for educational facilities, which often strive to promote sustainability and responsible construction practices. In conclusion, steel frame formwork is a suitable choice for the construction of educational facilities due to its strength, stability, flexibility, and cost-effectiveness. Its ability to withstand heavy loads, provide a secure working environment, and be customized to meet specific requirements makes it an ideal option for creating functional and efficient learning spaces.

- Q: What are the different types of support beams used with steel frame formwork?

- Construction projects commonly use several types of support beams in conjunction with steel frame formwork. These beams are crucial for providing stability and strength to the formwork system. Some of the support beams used with steel frame formwork include: 1. H-beams: These beams, shaped like the letter "H," are frequently used and have excellent load-bearing capacity due to their high-strength steel composition. 2. I-beams: Also known as universal beams, these beams have a cross-section shaped like the letter "I" and are ideal for bearing heavy loads. They are commonly employed in large construction projects that require high strength and stability. 3. Box beams: With a rectangular or square cross-section resembling a box, these beams possess a remarkable load-bearing capacity. They are typically utilized in projects where heavy loads need support. 4. Channel beams: Channel beams, or C-beams, have a cross-section shaped like the letter "C." They serve as secondary support beams in steel frame formwork, enhancing strength and stability. Channel beams are often used alongside other types of support beams. 5. Lattice beams: These lightweight and versatile support beams have a lattice-like structure. They are commonly employed in steel frame formwork to span long distances and offer a high level of flexibility. The selection of support beams for steel frame formwork depends on factors such as load requirements, project specifications, and budget constraints. Choosing the appropriate support beams is crucial to ensure the safety and stability of the formwork system throughout construction.

- Q: What are the different types of edge profiles used with steel frame formwork?

- There are several different types of edge profiles that are commonly used with steel frame formwork. These profiles are designed to enhance the functionality and durability of the formwork system. One of the most common edge profiles is the chamfered edge. This type of profile features a sloping edge that helps to prevent the buildup of concrete on the formwork surface. The chamfered edge also facilitates the removal of the formwork once the concrete has cured. Another popular edge profile is the rounded edge. This profile is characterized by its smooth, curved shape, which helps to reduce the risk of injury during construction. The rounded edge also allows for easier cleaning and maintenance of the formwork system. A third type of edge profile is the beveled edge. This profile features a slanted edge that helps to minimize the formation of sharp corners in the concrete. The beveled edge also assists in reducing the likelihood of cracking or chipping at the edges of the formwork. Additionally, some steel frame formwork systems may incorporate a recessed edge profile. This type of profile creates a groove or channel along the edge of the formwork, allowing for the insertion of reinforcement bars or other structural elements. The recessed edge profile helps to ensure proper alignment and positioning of these components within the concrete structure. In summary, the different types of edge profiles used with steel frame formwork include chamfered edges, rounded edges, beveled edges, and recessed edges. Each profile offers unique benefits in terms of concrete placement, formwork removal, safety, and structural integrity. The choice of edge profile will depend on the specific requirements of the construction project.

- Q: What are the different types of clamping systems used with steel frame formwork?

- There are several types of clamping systems used with steel frame formwork, including wedge clamps, hook clamps, pin clamps, and adjustable clamps. These clamping systems are designed to securely hold the formwork panels together and provide stability during concrete pouring and curing.

Send your message to us

Scaffolding Clamps En74 Formwork Fiberglass Scaffolding With Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords