SBS / APP Modified Bitumen Sheet Waterproofing Membrane for Ponds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

1. Asphalt roofing shingles are lightweight, glass fibre based bitumen strip slates. They are easily installed and the appearance of a highly decorative tiled roof finish. Asphalt shingles are exported to Britain, Asia, South America, Africa and so on.

Main Features of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

1) Size: 1000*333mm

2) Thick: 2.7mm, 5.2mm

3) Types: 3-Tab, Laminated, Mosaic, Fish-scale, Goethe

4) 12 colors

5) Weight: 9.5-12.5kgs/m2

6) Packing: 21pcs or 16pcs/bundle, 800-1000bundles/20' GP, wood pallet

7) Accessories: bitumen mastic, nails, roof underlayment

8) Warranty Time: 20-30 years

9) Temperature: -45°C to 130°C

10) Certificates: ISO14001:2004, ISO9001:2008

Specifications of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

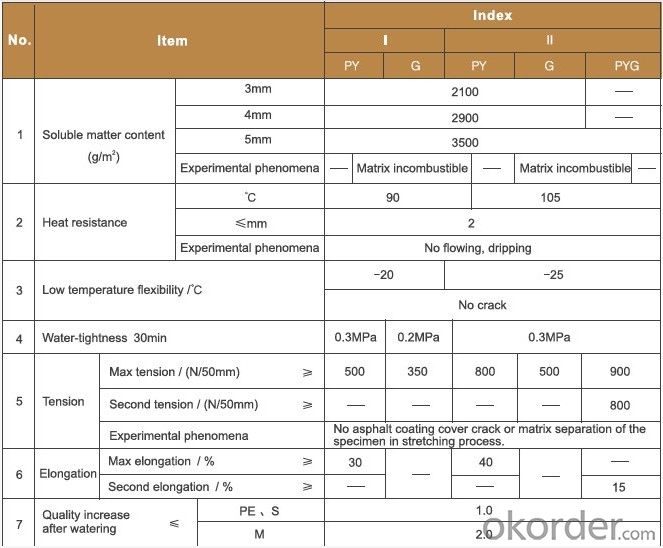

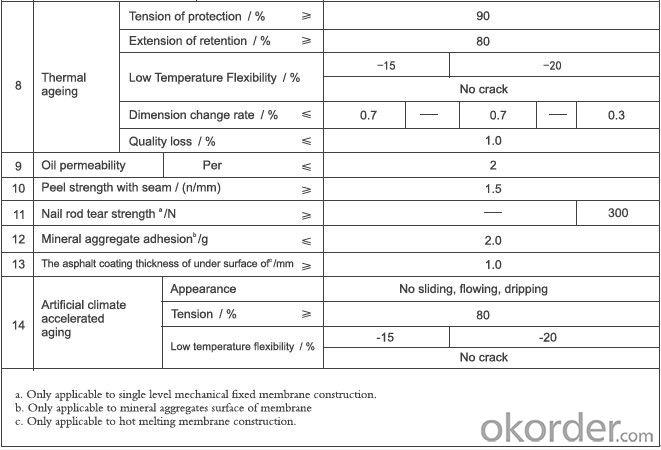

Physical Performance: Executive GB18242-2008

Storage and Transportio

Applications of EPDM Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

IMages of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

FAQ:

Q1.:What are we supplying?

A1:We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

Q2: How Many years experience do we have?

A2:We have exported to more than 20 countries in the past 15 years.

Q3.:Do you provide samples for us?

A3:Yes,We will provide samples for free.Waiting for your your good news.

- Q: Are waterproofing membranes resistant to jet fuel?

- Waterproofing membranes are typically crafted to withstand the infiltration of water and other liquids. However, jet fuel, being an extremely volatile and corrosive substance, can present a significant challenge to the effectiveness of these membranes. While certain membranes may offer some resistance to jet fuel, it is generally advised to take extra protective measures when handling such hazardous materials. To achieve the highest level of protection against jet fuel, it is recommended to utilize specialized membranes explicitly engineered to endure the corrosive impact of this substance. Such membranes are usually constructed from materials like polyurethane or epoxy, which have proven to be more resilient to jet fuel compared to standard waterproofing materials. Furthermore, it is essential to take into account the specific application and environmental conditions when assessing a waterproofing membrane's resistance to jet fuel. Factors such as temperature, duration of exposure, and concentration of the jet fuel can influence the membrane's performance. Regular inspections and maintenance are also necessary to identify any signs of degradation or potential weaknesses in the membrane. In conclusion, while certain waterproofing membranes may offer some resistance to jet fuel, it is crucial to employ specialized membranes and implement additional protective measures to ensure optimal performance and safeguard against the corrosive effects of jet fuel.

- Q: Can a waterproofing membrane be used for a hotel?

- Yes, a waterproofing membrane can be used for a hotel. Waterproofing membranes are commonly used in construction to protect buildings from water damage. In the case of a hotel, a waterproofing membrane can be applied to various areas such as the roof, foundation, basements, bathrooms, and balconies to prevent water leakage and moisture penetration. This is especially important in areas where water exposure is likely, such as swimming pools, spa facilities, or areas with heavy rain or high humidity. Installing a waterproofing membrane in a hotel can help maintain the structural integrity of the building, prevent mold and mildew growth, and ensure a comfortable and safe environment for guests.

- Q: Can a waterproofing membrane be used for a hospital basement?

- Yes, a waterproofing membrane can be used for a hospital basement. Waterproofing membranes are often used in basements to prevent water infiltration and protect against moisture-related issues such as mold and mildew growth. In a hospital setting, where maintaining a clean and hygienic environment is crucial, using a waterproofing membrane can help ensure the basement remains dry and free from water damage.

- Q: Can waterproofing membranes be used on utility manholes?

- Yes, waterproofing membranes can be used on utility manholes. Waterproofing membranes are specifically designed to provide a barrier against water infiltration, making them suitable for use in areas where water is present, such as manholes. These membranes are typically applied to the walls and floors of the manhole to prevent water from seeping through and causing damage to the structure or the utilities within. By effectively sealing off the manhole, waterproofing membranes help to maintain the integrity and functionality of the utilities and prevent water-related issues such as corrosion, leaks, and the degradation of materials. Additionally, waterproofing membranes can also provide protection against other elements such as chemicals, gases, and soil contaminants that may be present in or around the manhole. Therefore, using waterproofing membranes on utility manholes is a common practice to ensure their long-term durability and functionality.

- Q: What are the requirements for frost resistance of basement floor polymer waterproofing membranes?

- High polymer modified asphalt waterproofing membrane is -30 degrees.

- Q: Can a waterproofing membrane be used for walkways or pedestrian bridges?

- Certainly! Walkways or pedestrian bridges can indeed utilize waterproofing membranes. These membranes are specifically engineered to establish a barrier that effectively hinders water penetration, thereby averting potential harm to the structure. When a waterproofing membrane is applied to the surface of a walkway or pedestrian bridge, it effectively safeguards the underlying construction from water infiltration, thereby augmenting its endurance and longevity. This aspect becomes particularly crucial in regions that experience heavy rainfall or when the walkway or bridge is exposed to water sources like rivers or lakes. Moreover, apart from their primary function, waterproofing membranes can also offer supplementary advantages such as enhancing slip resistance and shielding against chemicals or pollutants.

- Q: Does a waterproofing membrane require any curing time before it can be exposed to water?

- Yes, a waterproofing membrane generally requires a curing time before it can be exposed to water. The specific curing time may vary depending on the product and manufacturer's instructions. It is important to allow the membrane sufficient time to cure and bond properly to ensure its effectiveness in preventing water penetration.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- A waterproofing membrane is specifically designed to shield building materials from water damage. Its purpose is to act as a barrier, preventing water from infiltrating the structure and causing harm. Typically, the membrane is applied to areas prone to water intrusion, such as roofs, basements, and foundations. By creating a watertight seal, it effectively stops water from seeping through and harming the building materials. This safeguard is essential in maintaining the structure's integrity and preventing issues like mold growth, rot, and material decay. However, it's crucial to acknowledge that the effectiveness of a waterproofing membrane can vary based on the product's quality and proper installation. Regular maintenance and inspections are also necessary to ensure the membrane remains intact and continues to safeguard against water damage.

- Q: Can a waterproofing membrane be used for swimming pools?

- Yes, a waterproofing membrane can be used for swimming pools. Waterproofing membranes are commonly used in swimming pool construction and renovation projects to prevent water leakage and ensure the pool remains watertight. These membranes are specifically designed to withstand constant exposure to water and provide a durable and long-lasting solution for swimming pools.

- Q: Are there any limitations to using a waterproofing membrane?

- Yes, there are some limitations to using a waterproofing membrane. One limitation is that the membrane can be punctured or damaged during installation, which can compromise its effectiveness. Additionally, waterproofing membranes may not be suitable for all types of surfaces or structures, and certain conditions such as extreme temperatures or excessive movement can affect their performance. Moreover, the lifespan of a waterproofing membrane can vary depending on factors like maintenance, exposure to UV rays, and overall wear and tear.

Send your message to us

SBS / APP Modified Bitumen Sheet Waterproofing Membrane for Ponds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords