S Type anti-corrosive fiberglass centrifugal pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of S Type anti-corrosive fiberglass centrifugal pump Description

The fiberglass centrifugal pump combines the motor and the pump components as a whole, relatively compact, easy to install with small power. It is mainly used in petrochemical, smelting, dyes, printing and dyeing, pesticides, pharmaceuticals, rare earth, fertilizer and other industries. The fiberglass centrifugal pump can transport slightly solid particles, not easy to crystallize. This pump is the essential ideal equipment for the corrosive media like some non-oxidation acid of not more than 100℃ (some acid temperature can reach 120℃).

2. Main Features of S Type anti-corrosive fiberglass centrifugal pump

•The products’ performance reaches the requirement of the trade standard JB/T8688-1998” plastic centrifugal pump”.

•Standardizing design, beautiful and dignified contour, reasonable and compact structure, universal parts and components, strong mutual changeableness.

•Optimum design of hydraulic model through Computer enables energy saving and high-efficiency

•Wetted components adopt phenolic fiberglass, through shaping under the conditions of high temperature and hot pressure, it has high strength and strong anti-corrosive performance.

•Axis sealing adopts Teflon mechanical sealing of outer-installing type with anti-strong corrosion and has extensively suitable scope with simple and reliable sealing.

•Single installation and convenient maintenance

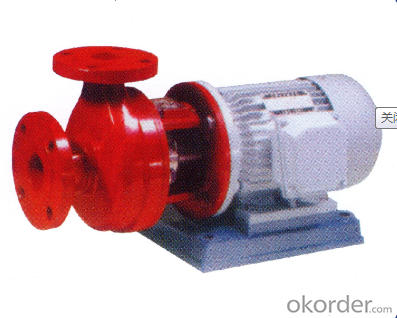

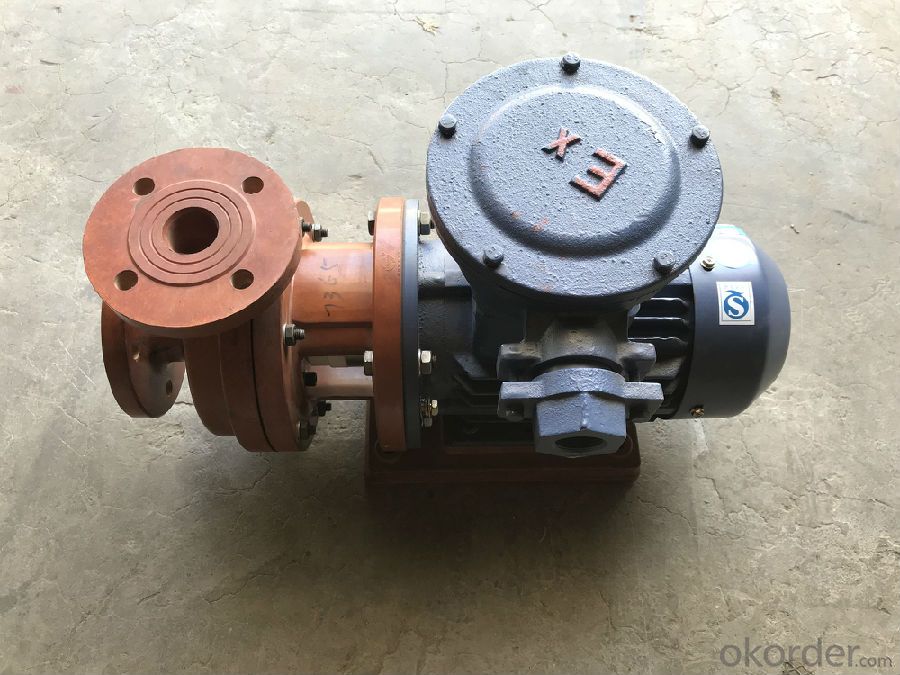

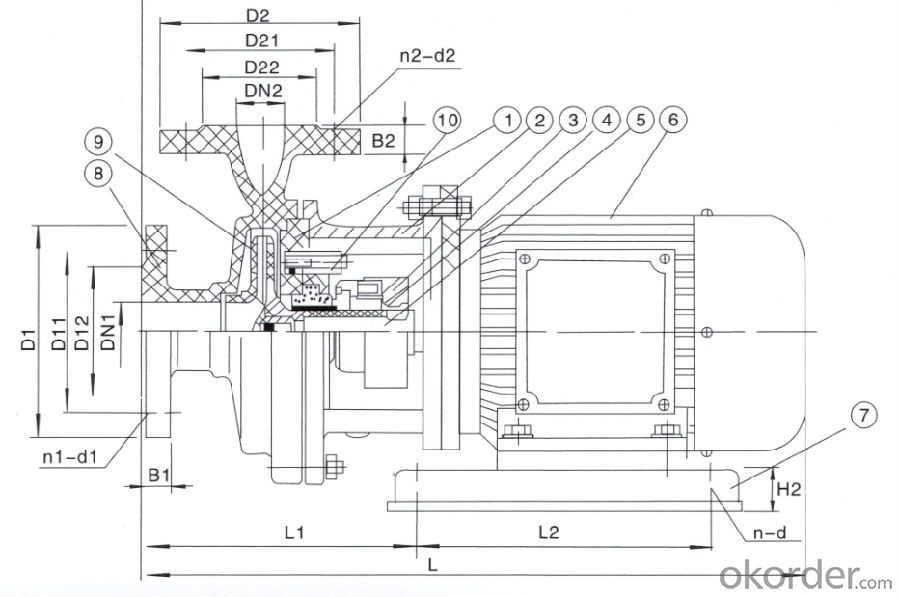

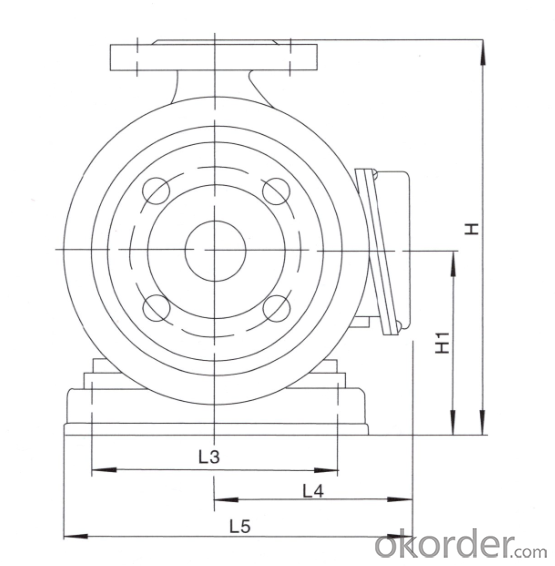

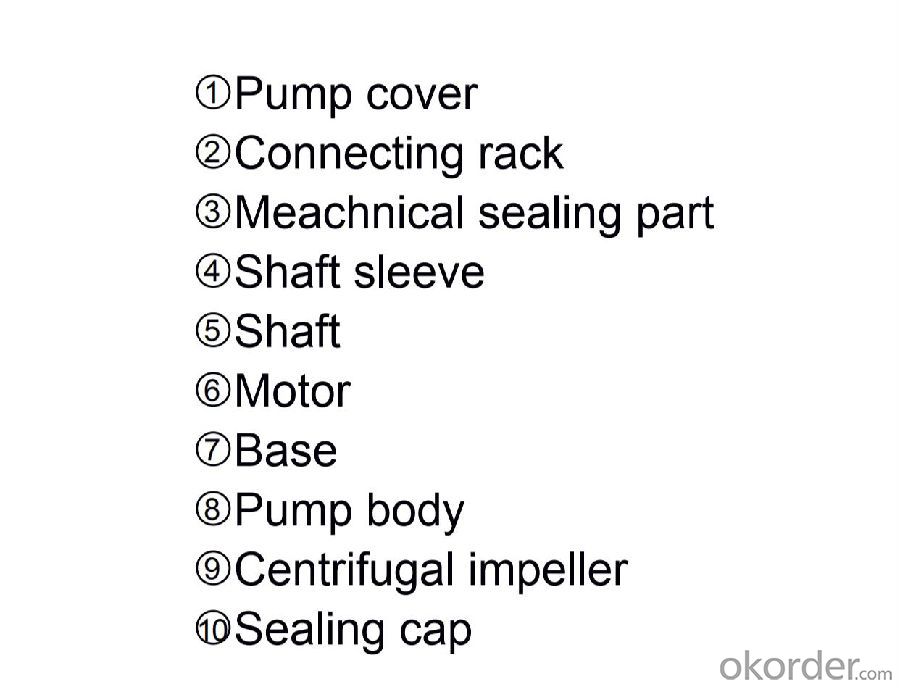

3. S Type anti-corrosive fiberglass centrifugal pump image

4. S Type anti-corrosive fiberglass centrifugal pump Specification\

Performance parameter Type | Q -Flow M3/h | H-Head M | Speed-n r/min | Efficiency % | NPSHr m | Motor capacity kW |

S25X25-12.5 | 3.2 | 12.5 | 2900 | 36 | 3 | 0.55 |

S40X32-20 | 6.3 | 20 | 42 | 3 | 1.1 | |

S40X32-32 | 6.3 | 32 | 35 | 3 | 2.2/3.0 | |

S50X40-20 | 12.5 | 20 | 53 | 3 | 2.2 | |

S50X32-32 | 12.5 | 32 | 48 | 3 | 4.0 | |

S65X50-20 | 25 | 20 | 62 | 3 | 3.0 | |

S65X50-32 | 25 | 32 | 57 | 3 | 5.5 | |

S80X65-32 | 50 | 32 | 65 | 4 | 7.5/11 | |

S100X80-50 | 100 | 50 | 68 | 5 | 22/30 |

5. Instructions

• The motor's revolving direction should be in conformity with the direction of pump's revolving direction pan. In order to protect pump from being damaged due to revolging in opposite direction, please first trial the revolving direction with hand to confrim the correct direction, then start the pump.

• Before starting, make the pump to be full of liquid; strictly forbid using concentrated acid.

• Don't allow pump idling without liquid, otherwise, the sealing end surface will be damaged due to dry friction.

- Q: The suction pump has a nominal suction range of 30 metersHow deep can a well be sucked?Well, sixteen meters,

- A standard atmospheric pressure can be 10.33 meters to 30 meters of water, suction is atmospheric pressure there are three standard atmospheric pressure so high? This is impossible in general, remove the vaporization removed 0.5 meters critical yo,

- Q: What does the pump mortar do?

- Concrete pump before the need to transport water and pump pump material, dredge pipeline. In accordance with the technical specification for concrete pumping construction (JGJ/T10 - 1995), pumping concrete, pump mortar generally use cement slurry

- Q: What is the principle of a turbopump?

- A machine that converts the energy contained in a fluid medium into mechanical work [turbine]. Also known as turbines, turbines. Turbine is the transliteration of English turbine, derived from the Latin word "turbo", meaning "rotating object". The working conditions of turbines are different from those of the employed ones, so their structure types are various, but the basic working principle is similar. The most important component of a turbine is a rotating element (rotor or impeller) that is mounted on a turbine shaft and has blades uniformly arranged along the circumference. The energy of the fluid is converted into kinetic energy in the flow through the nozzle, and when the fluid passes through the rotor, the fluid impacts the blade and drives the rotor to rotate, thus driving the turbine shaft to rotate. The turbine shaft drives the other machinery directly or through the transmission mechanism, and outputs mechanical work. According to the turbine working fluid used can be divided into different turbine (used as a power source of Hydropower Station) and steam turbine (used in thermal power plant, ship propulsion), gas turbine (used as jet propulsion, ship power, and power plants, with a small peak load power station and air turbine (only) as a small power).

- Q: The distance from the pump button to the ground

- After confirming that the fire pump has started running, issue a command signal to the hydrant button to light the green answer light.

- Q: What is the "variable" of a variable pump? Is the displacement change or the flow change? Thank you

- There are many ways to change the variable pump flow: by changing the eccentricity to change the piston stroke length (radial piston pump, the frequency change principle) motor speed to adjust the flow (such as gear pump flow control principle).

- Q: Why can't the inlet of centrifugal pump be negative pressure?

- Can be negative pressure ah, the negative pressure here refers to the pressure is less than the atmospheric pressure, but the pressure can not be too low, to prevent water vapor below the saturated vapor pressure, so that water vaporization, cavitation phenomenon, the centrifugal pump will be considered.

- Q: There are second cutting, third cutting, why three times?

- So some pumps are written in the back of XXXX-125A or B, that is, the impeller nominal diameter is 125, A is through a cut, B is the 2 cutting. To reach the applicable conditions, only the calculation is not enough, but also after cutting to test to determine.

- Q: Is the flow meter in front of the pump or after the pump?

- After the pump, the reasons are as follows, before the pump, you pump fluid through the pump will produce negative pressure in front of the pump, negative pressure on the flow of the life of the impact, the pump will not, Suzhou first Chi meter

- Q: Why can't the centrifugal pump pump the vacuum?

- Condition:The pump shell must be filled with liquid under certain installation height and running without leakage.What is the phenomenon of centrifugal pump? What harm does it have? How to eliminate?)

- Q: Attention should be paid to the use of pumps?

- 1, pump shaft packing completely worn, it is necessary to add in time, if you continue to use the water pump will leak. The direct effect of this is the increased energy consumption of the motor, which will damage the impeller. 2, the use of pumps in the course of a strong vibration, then must stop to check the reasons, or the same will cause damage to the water pump. 3 gear pump valve Water Leakage, some will use the soil into the water pump inlet tube, the water washed in the end valve, this is indeed undesirable. Because when the dry soil into the inlet pipe, when the pump started working, these dry soil will enter the pump, which will damage the pump impeller and bearings, which shorten the service life of the pump. When the valve Water Leakage must take to repair, if it is serious that it is necessary to replace the new. 4 after the use of pumps must pay attention to maintenance, for example, when the pump is exhausted, we should put the water pump who put clean, it is best to remove the water pipe, and then rinse with water. 5 water pump on the tape should also be written down, and then always flush, and then light out to dry, do not put the tape in the dark damp place. Water pump tape must not be stained with oil, not to tape coated with some sticky things.

Send your message to us

S Type anti-corrosive fiberglass centrifugal pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords