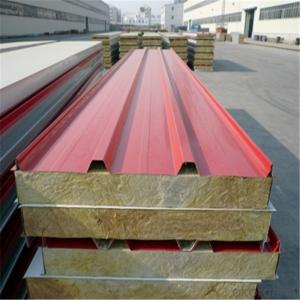

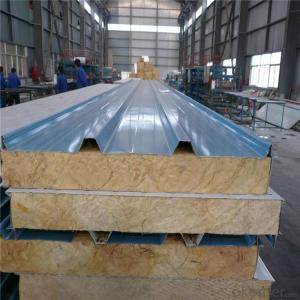

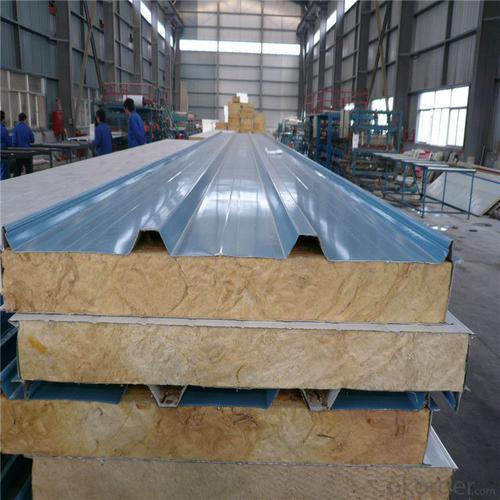

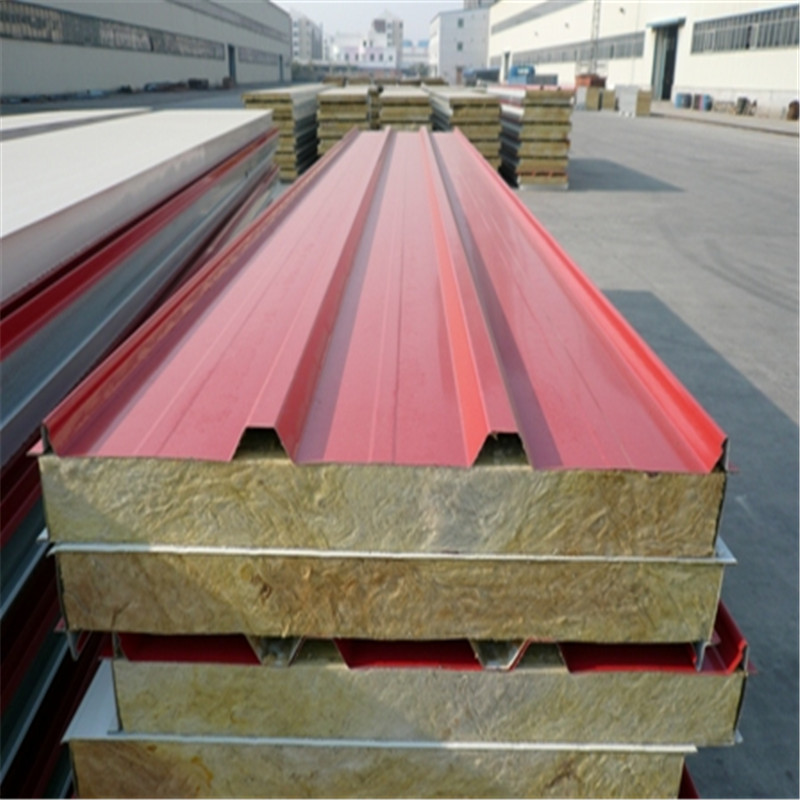

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

Description of rock wool sandwich panels:

The rock wool, which we call it “mineral wool”, is made from blast furnace slag, phosphorus slay, and coal ash through fusion. This is unreal rock wool with the features of high slag and has a lot of dust.

Rock Wool Sandwich Panel advantages

For more than ten years, sandwich panels with rock wool cores have been used successfully in a quick way of construction, having lots of advantages compared to conventional building systems:

Fast installation and convenient handling

Crane assembly and no scaffolding required

No thermal bridges and good thermal insulation properties

Plenty of design with choice of profiles and colours

Panels can be installed horizontally or vertically

Reliable robust mechanical performance

Outstanding non-combustible and acoustic performance

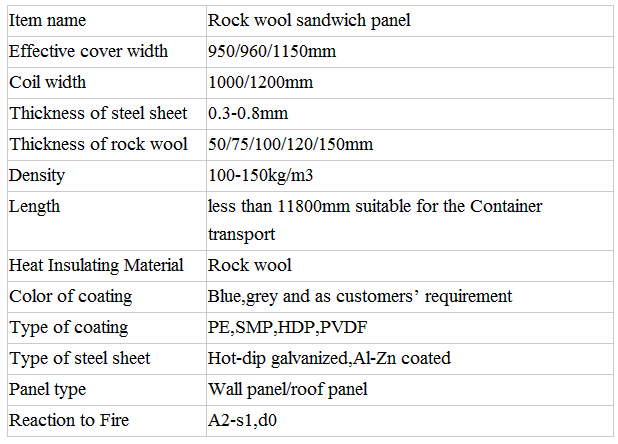

Specification of rock wool sandwich panels:

Applications

Rock Wool Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, fire rated and acoustic sandwich panels for workshops,warehouse, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

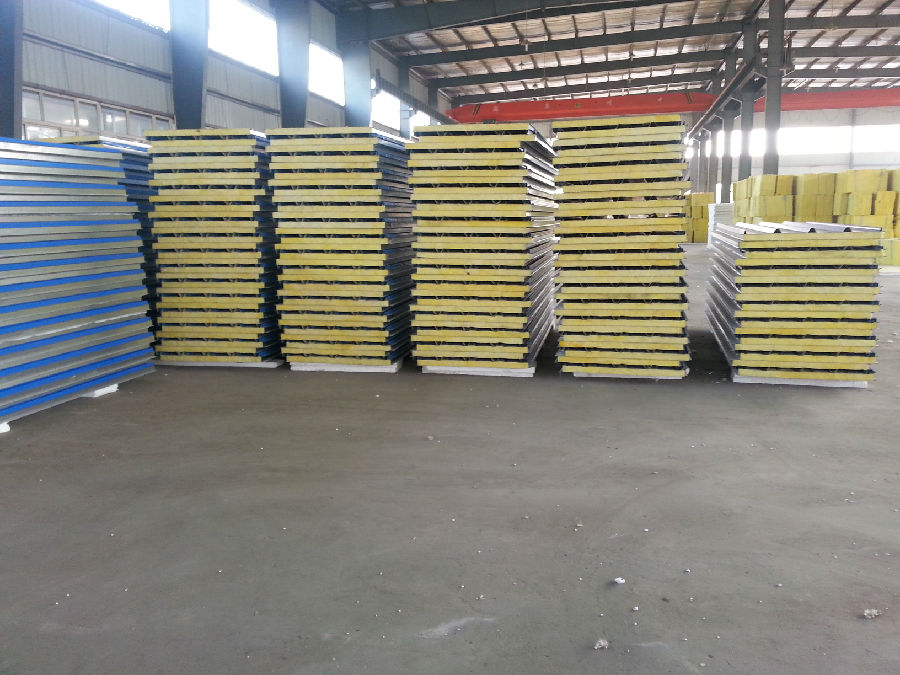

Workshop of rock wool panels

- Q: What is the acceptance criteria for rock wool sandwich panels?

- The thickness of the insulation layer and the thickness of the thickness of the thick galvanized layer and so on

- Q: Solid wood sandwich board how much money a piece

- No-name card (no license) 50 ~ ~ 60 yuan a brand, but the quality of the general 70 ~ ~ 90 yuan a brand, brand products (real 3A) more than 120 yuan each! Hope to help you, please adopt

- Q: Hanging plate, color plate, sandwich panels, pressure plate the same?

- Sandwich panels and Caigang sandwich panels is one thing, are double-color steel plate folder folder insulation material, food production workshop with sandwich panels can

- Q: Is the foam sandwich plate formaldehyde?

- Use to enjoy the formaldehyde detector under the test to know whether it contains formaldehyde, and large screen real-time display, triple alarm preset function, Portable compact hand.

- Q: We want to build the activities of the board room is used as a dormitory, what materials used sandwich board good? What is the price of polystyrene board and rock wool board? As a dormitory board room in the height of the national standard? How high should it be?

- Mainly to see the use of activities, fire or rock wool sandwich board is good

- Q: What is the difference between the sandwich panel and the composite board?

- Metal sandwich panels are made of two-layer metal panels (or other material panels) for the surface material, insulation materials to do the core material, with adhesive composite or direct foam curing molding compound. Building insulation sheet industry in the insulation board refers to the sandwich panels, composite board is popular called. Metal composite panel in the industry refers to a layer of metal plate covered with another metal plate, in order to reduce the use of the effect (corrosion resistance, mechanical strength, etc.) under the premise of saving resources and reduce the cost of the effect.

- Q: Sandwich panel prices, and specifications

- Generally 0.4MM-1MM steel clip 50MM foam, rock wool, polyurethane and other things. Prices generally range from 55-180. This depends on the specific circumstances to set, the bubble the cheapest, polyurethane expensive side

- Q: 50mm thick roof color steel sandwich board price is generally how much money a m2?

- Depends on the thickness of the color plate, different thickness of the color plate is not the same. For example: color plate thickness: 0.28mm thick: 0.2mm need 40 yuan / m.

- Q: Foam sandwich board in line with the fire building requirements? There is no regulatory requirements in this area? I was in Jiangsu !! Thank you

- The common application of new composite sheet. ??????????????????????????????? The new composite sheet is mainly used in the exterior wall of the steel structure plant, the roof, the gymnasium's light roof, the clean room interior cut, the clean area roof, the cold storage box or the partition plate, the construction site office and the construction workers collective dormitory, Relief temporary resettlement housing, some units will also be used for composite materials workshop, office, rooms and even operating room partition. Now the implementation of building energy efficiency standards, the foam composite sheet is also widely used in building exterior insulation layer. The use of new composite materials in the building is very wide, the use of a lot, its combustion performance and fire resistance to the building's fire safety situation greatly affected.

- Q: Color steel sandwich panels how much consumption

- Consumption is mainly based on the need to build the room size to calculate, the general consumption of 2% to 5%

Send your message to us

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords