Rock wool sandwich panels for prefabricated houses with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock wool sandwich panels for prefabricated houses with best price

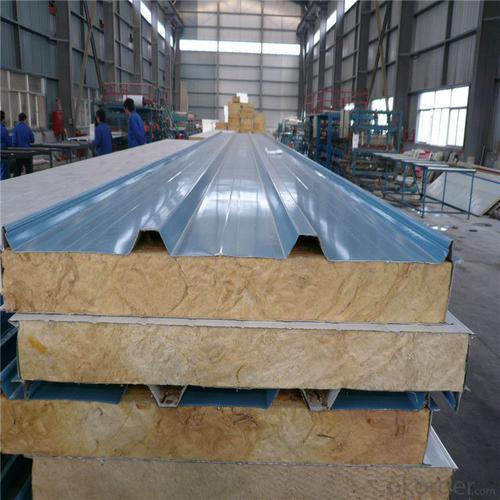

Rock Wool Sandwich Panel advantages

For more than ten years, sandwich panels with rock wool cores have been used successfully in a quick way of construction, having lots of advantages compared to conventional building systems:

Fast installation and convenient handling

Crane assembly and no scaffolding required

No thermal bridges and good thermal insulation properties

Plenty of design with choice of profiles and colours

Panels can be installed horizontally or vertically

Reliable robust mechanical performance

Outstanding non-combustible and acoustic performance

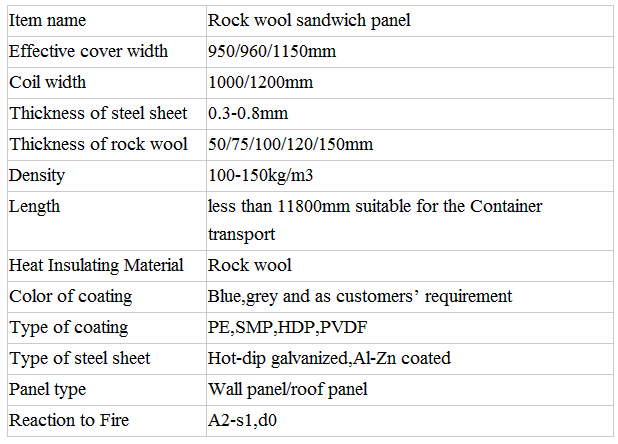

Specification of rock wool sandwich panels:

Applications

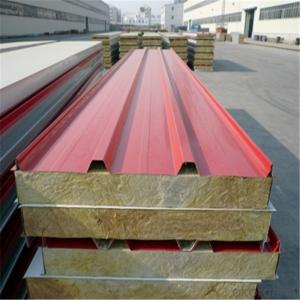

Rock Wool Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, fire rated and acoustic sandwich panels for workshops,warehouse, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

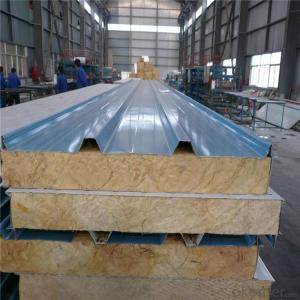

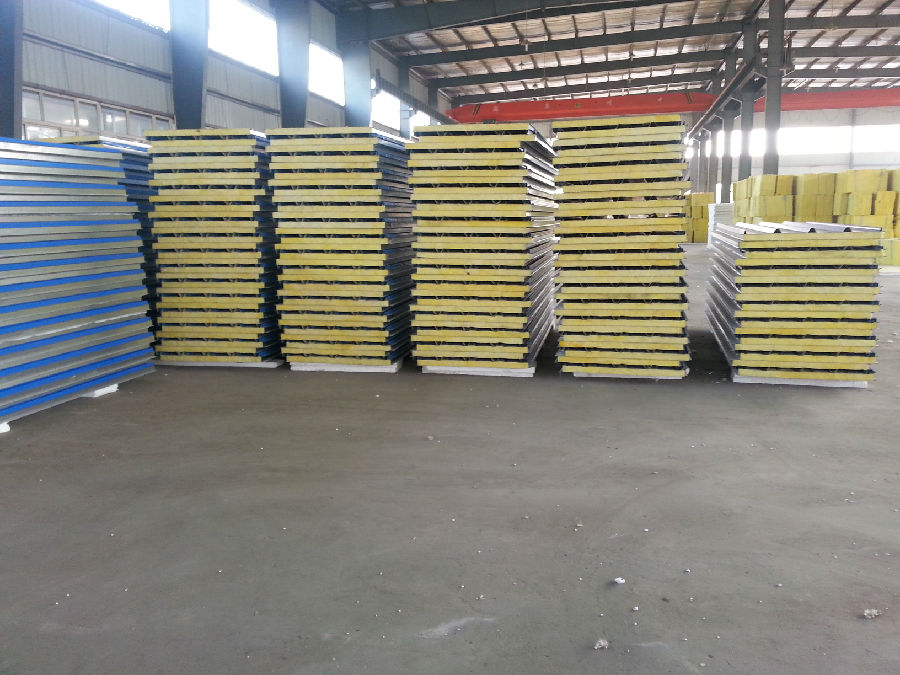

Workshop of rock wool panels

- Q: The Development Trend of Color Steel Sandwich Board

- Rockock structure rock wool composite board (rock wool color steel sandwich panel) is characterized by: high strength: only fixed at both ends, no purlin system, single span up to 12m high fire: high fire rating, up to 4 hours fire resistance Durability: in line with the highest standards of durability in Europe, to maintain the design of the building properties Multi-function: set fire, thermal insulation, sound insulation in one beautiful: large span mirror flat, beautiful metal appearance, comparable to aluminum curtain wall flexibility: flexible design Diverse, installation Flexible installation: easy installation, shortening construction cycle Economy: saving purlins, reducing total building costs, reducing total cost of product through FM certification (indicating that the product or service has passed the highest standards of the United States and international testing)

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Specific solutions: 1 to reduce the brine wave degrees; 2 Add GX-1 # Magnesium Modifier; 3 to do a good job of ventilation and cooling work.

- Q: What are the benefits of color steel?

- Color plate is made of polystyrene foam sandwich panel surface, closed-hole self-extinguishing polystyrene foam to do the core material, through the automatic continuous molding machine will be colored steel plate with high-strength adhesive after bonding A new type of composite building materials, mainly for public buildings, industrial plants, roofs, walls and clean rooms and the combination of cold storage, building joints, kiosks, etc., it has a heat, waterproof once completed, construction speed, durable, Nice and so on

- Q: Sandwich board machine how much money

- Metal insulation sandwich board production line, probably in the 23-30 million range, the current OKorder Changxing, Baosheng, Po day, good quality, finished product width 970,980,950 type,

- Q: How to choose the type of steel structure plant roof sandwich panels

- Steel plant roof, should be based on the use of plant sandwich panels: 1, the general plant roof with ordinary double-pressure steel plate polyethylene foam sandwich panels, sandwich material thicker, insulation, the better the insulation effect. 2, into the deep larger house, and the need for natural light of the plant, the roof sandwich panels should use transparent, translucent sandwich panels. For example: transparent plastic sandwich panels. 3, the fire requirements of the plant, the roof with fire double-sided steel plate Yanmian sandwich panels, can also have, insulation, insulation, fire performance. This sandwich panel must meet the design requirements of the fire rating. And, the factory floor of the steel structure, should brush fire paint; doors and windows with fire doors and windows.

- Q: Color steel sandwich board surface rust how to do

- The surface rust is because the color plate surface paint off the inside of the steel plate caused by oxidation. General this situation waiting for oxidation rust, perforation. Refurbishment is not impossible, but the cost is high. You can try to wash the rust with acid, Brush paint.

- Q: Sandwich panel prices, and specifications

- Y-2100 intelligent polystyrene sandwich board vertical production line, is our company according to the relevant requirements of the market for the bold design of their own innovative manufacturing in line with the "building partition with light strip" JG / T169-2005 standard production line self Equipment, size and cross-section size, product specifications in line with national recommended series. The production line will be divided into the storage process system, polystyrene particle grammar system, automatic feeding system, sandwich material mixing system, forming plate machine, casting system, mold recycling system, a product casting molding, the production of calcium silicate cement fiber pressure Plate pallet heart panel. A board machine production line can achieve the class output 600-800 square meters of finished products, automatic control of the production process, each production line required artificial 4-6 people.

- Q: Is the factory wall with a sandwich board fire clearance?

- Yanmian, then the fire temperature can reach 700 degrees, two glass wool can only reach 260 degrees, and then there are magnesium, and now the highest fire intensity of the material.

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- There are six kinds of core material: polystyrene sandwich panels that EPS sandwich panels (the market, the most widely used varieties); Extruded polystyrene sandwich panels that are XPS sandwich panels; Rock wool color steel sandwich panels Rigid polyurethane sandwich panels that PU sandwich panels; Trimer sandwich panel that is PIR sandwich panels; Phenolic sandwich panels that are PF sandwich panels; Rock wool sandwich panels are RW sandwich panels. Product performance: thickness 0.2mm ~ 1.0mm Core thickness: 50mm ~ 250mm Effective height: 1000mm, 1200mm, 960mm.950mm Scope: workshop, office walls, steel structure of the external walls Maintenance, decorative building materials, activities, such as office buildings Fire rating: B1 ~ B3 (flame retardant: melting) Moisture absorption: 3.9 (%)

- Q: Not the old bubble sandwich board prices

- Sandwich board 40 yuan per meter type of 5.6 meters 25 sandwich panel 5600 yuan C steel 14 1100 yuan accessories 400 yuan enough sandwich board is 0.25MM / 0.2MM 7.5CM

Send your message to us

Rock wool sandwich panels for prefabricated houses with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords