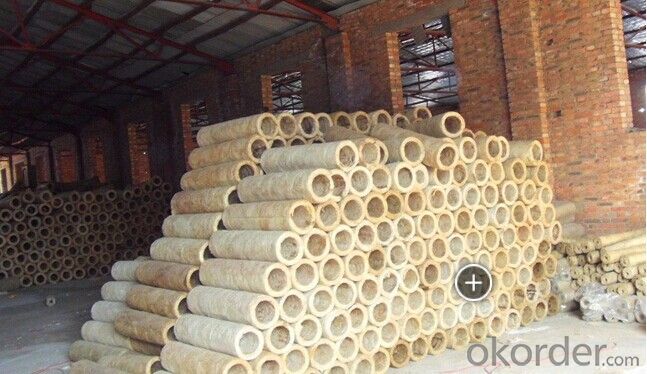

Rock Wool Roll Yellow Color Rock Wool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

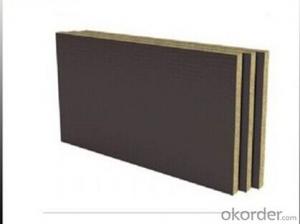

High quality and good price rock wool board

1)Fireproof Grade:A1

2)Heat conduct coefficient:0.030-0.044

3)Fiber Dia:4-7

The rock wool product is made from basalt as main ingredient which is made into the fiber in high speed centrifugal machine after melting at temperature about 1450°C. Adding the proportional resin, it can be processed into rock wool board, blanket and pipe according to the customer requirement.

Application:

1. Used for fire protection, thermal insulation in public, commercial and residential buildings.

2. Used for sound absorption in roofing, external wall, partition wall and floating floor.

3. Low density rock wool board suitable for roof and wall in thecture build

Reflective insulation material consists of one or two layers bubble or foam that are sandwiched between layers of 99.9% pure aluminum radiant barrier foil . this style can be used in a variety of applications because of its thin, lightweight properties. The bubble layers creates Maximum R value and Vapor barrier , the reflective foil on both sides allow it to reflect 97% of radiant heat away from a structure on the outside and back into a structure from the insides. This is why it works effectively in both hot and cold climates

1 | 99.9% pure aluminum |

2 | High Reflectivity 97% |

3 | Low Emissivity 0.003 |

4 | 0.04 mm thick aluminum foil |

5 | Single layer thick Polyethylene bubbles |

6 | 3.5mm+thickness |

7 | If Fire proof,the rate is Class A |

8 | 100% Vapor barrier |

- Q: External wall insulation rock wool board construction points and matters needing attention, know how much?

- The production enterprise of rock wool board insulation system should have professional guidance in the construction process, and cooperate with construction units and site supervision to do construction quality control work.Material access must be in accordance with specifications, quantity and quality requirements, after acceptance of qualified to storage, and should be kept by hand, is strictly prohibited open-air stacking. Curtain wall rock wool board should be overhead damp proof piling up.

- Q: Advantages of exterior wall energy saving and environmental protection heat insulation coating

- Although the market is rich in exterior wall insulation products, but inorganic thermal insulation materials in addition to A-class fire retardant performance and good insulation effect, but also has excellent insulation system structure without network. In simple construction, and buildings with life, water resistant anti crack and anti hollowing fields occupy an increasingly important position.

- Q: What is mineral fiber cotton? Yes, it's insulation.

- Mineral fiber cotton is a kind of cotton fiber which is made from various mineral raw materials by melting and fiber forming and by surface treatment with different organic and inorganic reagents.

- Q: What are the advantages of inorganic fiber spraying in construction engineering?

- Inorganic fiber spraying can be used for fireproof material, inorganic fiber spraying is widely used in the field of building insulation in 2003 China promulgated the "building materials industry standards of mineral wool insulation coating JC/T909-2003" specification of the inorganic fiber spraying construction and application of insulating layer. In recent years, building insulation layer caused by frequent fires, especially in the CCTV new site north side building fire is most well known, these frequent fires cause the domestic construction industry pay more attention to fire insulation materials, inorganic fiber spraying insulation material fire a advantage is to get attention.

- Q: Does water paint spray fire in underground space?

- NeededWater based brand fire retardant paint thickness is determined by base material, such as wood, steel structure, etc.:1. ultra thin structure fire retardant coating (0-3mm)2. thin steel structure fire retardant coating (3-7mm), fire-resistant 2-5h3. thick steel structure fire retardant coating (7-45mm), applicable to high-rise civil buildings, columns, general industrial and civil construction, fire up to more than 3H4. mineral cotton fire retardant insulation coating

- Q: What are the common thermal insulation materials?

- In architecture, it is customary to control the flow of heat through the houseMaterials called thermal insulation prevent the heat from entering the room from being called heat insulation material. Insulation, thermal insulation materials insulation materials called duncan. The commonly used insulation materials can be divided into two categories: organic and inorganic. In its shapeCan be divided into fibrous, porous, microporous, bubble, granular, layered and many other, here are some of the more common materials are briefly introduced.

- Q: Fire retardant plywood does not belong to non-metallic refractory building materials

- Materials are inorganic active insulation materials, foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, vacuum insulation panel etc..

- Q: What are the types of insulation materials used in pipes and equipment?

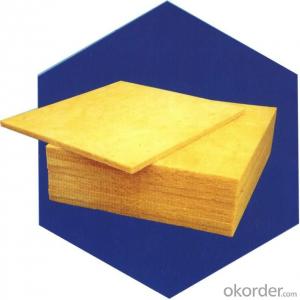

- Glass wool is a fibrous material made from the melting of glass or crushed glass. It consists of two kinds of short cotton and superfine cotton.Features: glass wool can maintain good insulation performance under high temperature and low temperature; has good elastic restoring force; has good acoustic performance of acoustic noise. Have good sound-absorbing effect; good chemical stability, no aging performance unchanged, thickness, density and shape can be processed according to user requirements.Main applications: short cotton is mainly made of glass wool felt and felt. It is used for heat insulation and sound insulation of buildings, heat preservation and sound insulation of ventilation and air conditioning equipment. Superfine cotton master

- Q: Exterior wall insulation putty powder construction needs to pay attention to what problems?

- The production enterprise of rock wool board insulation system should have professional guidance in the construction process, and cooperate with construction units and site supervision to do construction quality control work. Material access must be in accordance with specifications, quantity and quality requirements, after acceptance of qualified to storage, and should be kept by hand, is strictly prohibited open-air stacking. Curtain wall rock wool board should be overhead damp proof piling up. Plastering construction should meet the following requirements: rock wool board paste after surface treatment with plaster surface plate, scraping the mortar on the surface coated with a stainless steel spatula (thickness 1 ~ 1.5mm), and press the rock wool board surface fiber. Mortar should be configured in strict accordance with product instructions, configuration of the adhesive should avoid direct sunlight, and should be used within 2h.

- Q: Is the calorimeter for building materials calorific value?

- Hebi Huanuo coal testing equipment ZDHW-8000A high precision microcomputer automatic calorimeter for measurement of electric power industry, coal, metallurgy, petrochemical, environmental protection, quality inspection, cement, paper, geological exploration, scientific research institute and other departments to measure the coal, coke, petroleum, cement, brick and heat it solid or liquid fuel. In accordance with the national standard GB/T213-2008 "method" the requirements of the determination of calorific value of coal. The high precision microcomputer full automatic calorimeter is the main instrument in the coal quality laboratory.

Send your message to us

Rock Wool Roll Yellow Color Rock Wool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords