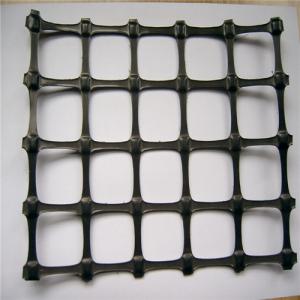

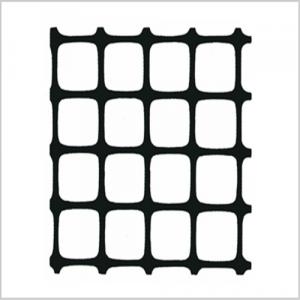

PP Biaxial/Unixial Geogrid Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP geogrid Description

PP geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

PP geogrid Specification

Tensile Strength: 15KN-15KN, 40KN-40KN, 50KN-50KN, etc

Roll Size: 3.95x100m, 2x50m, as request.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

PP geogrid Property

1) Not easy to produce static after friction.

2) Good flame retardant performance.

3) Strong anti-corrosion and rust resistance.

4) High bearing capacity, low elongation.

PP geogrid Application

1) Coal mine channel.

2) Slope protection in tunnel and expressway.

3) Anti-seismic reinforcement of buildings.

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q:What are the different testing methods for geogrids?

- Some of the different testing methods for geogrids include tensile strength testing, aperture size testing, creep testing, and durability testing. Tensile strength testing evaluates the geogrid's ability to resist pulling forces, while aperture size testing measures the size of the openings in the geogrid. Creep testing assesses the geogrid's deformation under constant load over time, and durability testing evaluates its resistance to environmental factors like UV exposure and chemical degradation. These testing methods help determine the performance and suitability of geogrids for various geotechnical applications.

- Q:Can geogrids be used in retaining walls for commercial developments?

- Yes, geogrids can be used in retaining walls for commercial developments. Geogrids are commonly employed as soil reinforcement materials in retaining wall construction. They provide stability and strength to the structure by distributing and confining the forces exerted by the retained soil. Their use in commercial developments ensures a reliable and long-lasting retaining wall system.

- Q:Are geogrids suitable for use in soft soil conditions?

- Yes, geogrids are suitable for use in soft soil conditions. Geogrids are typically made from high-strength materials such as polyester or polypropylene, which provide reinforcement and stabilization to weak or soft soils. They can effectively distribute loads, improve soil stability, and prevent soil erosion. Geogrids are commonly used in various civil engineering applications, including road and railway construction, embankments, and retaining walls, where soft soil conditions are present.

- Q:What factors should be considered when selecting a geogrid?

- When selecting a geogrid, several factors should be considered. Firstly, the intended application and the specific requirements of the project play a crucial role. Different geogrids are designed for various purposes such as soil stabilization, reinforcement, or erosion control. Secondly, the strength and durability of the geogrid are important considerations. The material composition, tensile strength, and resistance to environmental factors like UV radiation or chemicals should be evaluated. Additionally, the installation process and ease of handling the geogrid should be taken into account. Lastly, cost-effectiveness and the long-term performance of the geogrid should be considered to ensure an optimal selection.

- Q:Geocell of earthwork grid construction method

- What is geocellGeocell is a kind of three-dimensional grid lattice structure geocell, which is made of HDPE material, which is welded by high strength.What are the characteristics of geocell1, with flexible, transport may be collapsed, the construction can be a Lacheng mesh, fill soil, gravel, concrete and other loose material, which has the structure of strong lateral limit and rigid body.2, light material, wear resistance, chemical stability, light oxygen aging, acid and alkali resistance, suitable for different soil and desert soil conditions.3, the higher lateral restrictions and non slip, anti deformation, effectively enhance the bearing capacity of the subgrade and scattered load.4, to change the height of geocell, welding distance and other geometric dimensions to meet the needs of different projects.5, flexible and easy to transport small size, convenient connection, construction speed.

- Q:What is the GDL geogrid

- 2, to highlight the advantages of geogrid is deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project;3, the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, improve the service life of engineering.

- Q:What is the effect of junction strength on geogrid performance?

- The effect of junction strength on geogrid performance is significant. A stronger junction ensures better interlocking and connection between the geogrid's components, leading to enhanced load distribution and resistance against installation stress and long-term deformation. It allows the geogrid to effectively restrain and stabilize the soil, improving overall geotechnical performance and longevity.

- Q:Are geogrids suitable for use in bridge abutment reinforcement?

- Yes, geogrids are suitable for use in bridge abutment reinforcement. Geogrids are commonly used in civil engineering projects, including bridge construction, to provide additional support and reinforcement. They help to distribute loads, prevent soil erosion, and enhance the stability of the bridge abutments.

- Q:Can geogrids be used in ground reinforcement for recreational facilities?

- Yes, geogrids can be used in ground reinforcement for recreational facilities. Geogrids are commonly used to stabilize and reinforce soil, making them ideal for applications such as sports fields, playgrounds, and other recreational areas. They help to prevent soil erosion, improve load-bearing capacity, and enhance the overall stability and durability of the ground.

- Q:Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are made from high-strength polymers or other materials that have a high resistance to chemical degradation. This makes geogrids suitable for use in various environments, including those where exposure to chemicals is a concern. However, the specific chemical resistance of a geogrid may vary depending on the type of polymer used. It is recommended to consult the manufacturer's specifications or conduct appropriate testing to ensure compatibility with specific chemicals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial/Unixial Geogrid Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords