Reinforced Steel Bar Hrb400B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 160 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Reinforced Steel Bar Hrb400B

Description of Reinforced Steel Bar Hrb400B

1, Diameter: 5.5mm-10mm Reinforced Steel Bar Hrb400B

10m- 40mm Reinforced Steel Bar Hrb400B

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Reinforced Steel Bar Hrb400B

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

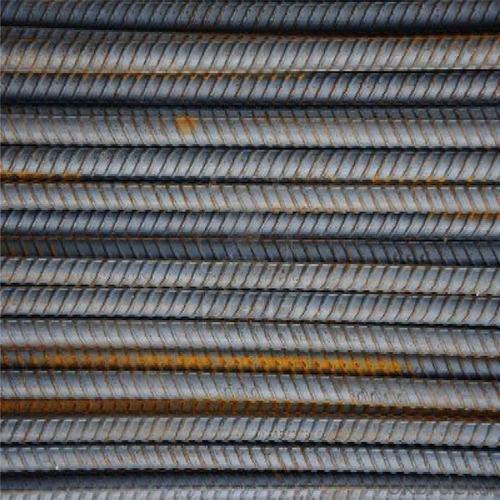

Products Show of Reinforced Steel Bar Hrb400B

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different methods of improving the creep resistance of special steel?

- There are several methods of improving the creep resistance of special steel, which are designed to enhance its ability to withstand long-term exposure to high temperatures and constant stress. Some of the methods commonly employed include: 1. Alloying: Special steel can be alloyed with specific elements to enhance its creep resistance. The addition of elements such as chromium, molybdenum, tungsten, and vanadium can significantly improve the material's ability to resist creep deformation. These alloying elements form strong carbides or intermetallic compounds, which impede the movement of dislocations and enhance the material's strength and resistance to creep. 2. Heat treatment: Precise heat treatment techniques can be employed to improve the creep resistance of special steel. Processes such as quenching and tempering, annealing, and normalizing can alter the steel's microstructure, leading to the formation of fine-grained and homogeneous structures that offer improved creep resistance. Heat treatment also helps in relieving residual stresses and improving the material's overall strength. 3. Grain refinement: Special steel can be subjected to processes that refine its grain structure, thereby enhancing its creep resistance. Techniques such as grain size reduction through controlled rolling, recrystallization, and severe plastic deformation can lead to the formation of smaller and more uniform grains. This refined microstructure hinders dislocation movement and improves the material's resistance to creep deformation. 4. Precipitation hardening: Special steel can be subjected to precipitation hardening methods, where the material is heated and then rapidly cooled to induce the formation of fine precipitates. These precipitates act as barriers to dislocation movement, improving the material's strength and creep resistance. 5. Surface modification: Special steel can be treated with surface modification techniques to increase its creep resistance. Methods such as shot peening, laser surface melting, and surface coatings can improve the surface integrity, reduce surface roughness, and introduce compressive residual stresses, all of which contribute to enhanced creep resistance. It is important to note that the selection and combination of these methods depend on the specific requirements of the application and the type of special steel being used. The aim is to optimize the material's microstructure, chemical composition, and surface characteristics to achieve the desired creep resistance and ensure long-term performance at elevated temperatures.

- Q: Can special steel be used in the telecommunications industry?

- Yes, special steel can be used in the telecommunications industry. Special steel, such as stainless steel or corrosion-resistant steel, can be utilized for various applications in telecommunications infrastructure, including tower structures, antenna components, cables, and connectors. These types of steel offer high strength, durability, and corrosion resistance, ensuring reliable and long-lasting performance in the telecommunications sector.

- Q: How is stainless tool steel used in the manufacturing of surgical instruments?

- Stainless tool steel is commonly used in the manufacturing of surgical instruments due to its desirable properties such as high corrosion resistance, durability, and ease of sterilization. It provides the necessary strength and precision required for surgical tools, ensuring their longevity and performance in various medical procedures. Additionally, stainless tool steel can withstand repeated exposure to sterilization methods like autoclaving, making it a reliable choice for surgical instrument manufacturing.

- Q: How does special steel perform in electrical conductivity applications?

- Special steel, due to its high electrical conductivity, performs exceptionally well in electrical conductivity applications. Its low resistance allows for efficient flow of electrical currents, making it ideal for various electrical and electronic components such as wiring, connectors, and conductors. Additionally, special steel's corrosion resistance properties ensure long-term performance and durability in demanding electrical environments.

- Q: What are the properties of tungsten alloys?

- Tungsten alloys have several notable properties. They possess a high melting point, excellent corrosion resistance, and superior strength. These alloys also exhibit remarkable density, making them ideal for use in various applications such as aerospace, defense, and medical industries. Additionally, tungsten alloys have good electrical and thermal conductivity, making them suitable for electrical contacts and heat sinks. Overall, their unique combination of properties makes tungsten alloys highly desirable for high-performance applications.

- Q: How does special steel contribute to the aerospace structural industry?

- The aerospace structural industry relies heavily on special steel due to its various important attributes needed for building aircraft components. Firstly, special steel possesses exceptional strength and durability, enabling it to withstand the extreme conditions and stresses experienced during flight. This is particularly crucial for critical components like landing gear, engine parts, and wing structures that face high temperatures, pressure, and vibrations. Additionally, special steel exhibits excellent corrosion resistance, which is essential for ensuring the long-lasting and reliable nature of aerospace structures. Aircraft are constantly exposed to harsh environments such as high humidity, saltwater, and chemicals, which can cause corrosion and degradation if not adequately protected. Special steel helps prevent these issues, ensuring the aircraft's structural integrity throughout its lifespan. Moreover, special steel offers other desirable properties including heat resistance, fatigue resistance, and weldability. These characteristics make it suitable for a wide range of aerospace applications such as constructing fuselage frames, engine mounts, fasteners, and hydraulic systems. By utilizing special steel in these components, aerospace manufacturers can achieve lightweight designs without compromising strength and safety. Furthermore, special steel empowers engineers to push the boundaries of aircraft performance by facilitating the development of advanced technologies. For example, the use of special steel alloys in turbine blades allows for higher operating temperatures, improving engine efficiency and reducing fuel consumption. This contributes to the overall sustainability and environmental friendliness of the aerospace industry. In conclusion, special steel is an indispensable material in the aerospace structural industry as it provides the necessary strength, durability, corrosion resistance, and other essential properties required for constructing aircraft components. Its contribution enables the development of safer, more efficient, and technologically advanced aircraft, ultimately benefiting the aerospace industry as a whole.

- Q: How does special steel contribute to improving product durability?

- Special steel contributes to improving product durability in several ways. Firstly, special steel is known for its high strength and toughness, which makes it more resistant to wear and tear. This means that products made with special steel are less likely to develop cracks, deformations, or other forms of damage during regular use. Additionally, special steel often has enhanced corrosion resistance properties, making it more resistant to rust and other forms of degradation. This helps to prolong the lifespan of products, particularly those exposed to harsh environments or extreme weather conditions. Moreover, special steel can also offer increased heat resistance, enabling products to withstand high temperatures without losing their structural integrity. Overall, the use of special steel in manufacturing processes significantly enhances the durability and longevity of products.

- Q: What are the properties of duplex stainless steel?

- Duplex stainless steel is known for its excellent combination of corrosion resistance and high strength. It has a two-phase microstructure consisting of equal amounts of ferrite and austenite, which provides it with superior toughness and resistance to stress corrosion cracking. Additionally, duplex stainless steel offers good resistance to pitting and crevice corrosion, making it suitable for use in various harsh environments. It also exhibits good weldability and is highly durable, making it a popular choice in applications such as chemical processing, oil and gas industries, and marine environments.

- Q: What are the main advantages of using special steel in the automotive racing industry?

- The main advantages of using special steel in the automotive racing industry are its high strength-to-weight ratio, excellent durability, and superior heat resistance. Special steel allows for the construction of lightweight yet strong components, enhancing the overall performance and speed of racing cars. Additionally, its exceptional durability ensures that the parts can withstand the extreme forces and vibrations experienced during racing, minimizing the risk of failure. Moreover, special steel's excellent heat resistance prevents deformation or weakening of components, even under high temperatures generated by the intense racing conditions.

- Q: What are the properties of silicon steel?

- Silicon steel, also known as electrical steel or transformer steel, has several important properties. It is characterized by low core loss and high magnetic permeability, making it highly efficient in electrical applications. Silicon steel is also known for its ability to generate minimal heat during operation, which is crucial for transformers and other electrical devices. Additionally, it exhibits excellent magnetic properties, such as high saturation flux density and low coercive force, allowing for efficient energy transfer and minimizing energy losses.

Send your message to us

Reinforced Steel Bar Hrb400B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 160 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords