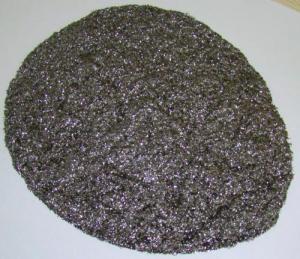

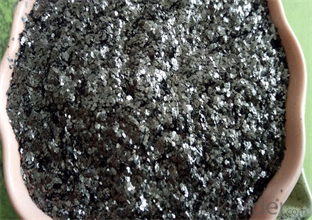

Raw Materials for Refractory:Natural Flake Graphite FC 89 with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

· Shape:powder

· Material: graphite

· FC Content (%): 89%min

· V.M Content (%): 2%max

· ASH Content(%): 9%max

· Moisture:1%max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Natural Flake Graphite

· Color:Black

· Size:-100MESH/200MESH/-325mesh or Smaller

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:powder

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: Preparation of refractory clay

- Is it to make refractories? Add some andalusite to the refractory mortar will improve the effect.

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will burst under sharp temperature difference of about 70-120 degrees and toughened glass of 200 degrees. It is not yet clear for the bursting temperature differences of the refractory glass. If the overall glass is heated evenly, it will have no significant change below 600 degrees, and it will deform with the increase of temperature until melting. The fire-resistant time of the glass you said is the time to heat the glass into the extreme temperature differences it can endure, which should not be more than 10 minutes

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: How is refractory material made?

- It is made from carbon materials.

- Q: What is the interior fireproof thermal insulation material?

- Polystyrene?board, extruded sheet and polyurethane are mainly used. Polystyrene?board is the cheapest, but the thermal insulation effect is ordinary. When absorbing water, it will deform. Other waterproof measures are needed to be made after insulating layer is done./

- Q: Can refractory be used as sealing element?

- It can. For example, fiber ceramics can resist high temperature! !

- Q: What are the types of refractory sealant?

- According to the environmental temperature of the region, it is divided into stpl-1 type, stpl-2 type, stpl-3 type. The three models are respectively applied to sealing repair of regular and irregular crack in asphalt / cement concrete roads, highways, airport runways, which are of different temperatures. Stpl-1 type: It is suitable for pavement temperature (0℃to 80 ℃) stpl-2 type: It is suitable for pavement temperature (-15℃to 60 ℃) stpl-3 type: It is suitable for pavement temperature (-30 ℃ to 40 ℃)

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory is widely used in industrial circle, such as metallurgy, chemical industry, petroleum, mechanical manufacturing, silicate and power, and its coonsumption is the maximum in metallurgy, accounting for 50% to 60% in total output. In order to improve slag-corrosion resistance of furnace lining, usually choose carbon-containing refractory. Refractory of various furnace lining are respectively: For the body, it is clay brick; as for the lower part, bosh and middle, it is SiC brick; for furnace bottom, it is carbon brick. Lattice brick is an important refractory product used in air heating furnace and regenerative chamber. Refractory is widely used in metallurgy. In order to improve slag-corrosion resistance of lining. Central line in tuyere and hearth are high-alumina brick. Refractory consumption is the maximum in metallurgy, accounting for 50% to 60% in total output. For the bosh and middle, it is SiC brick. In order to improve its thermal storage capacity: The furnace stack is clay brick. It is defined as refractory where the physical and chemical properties allows its use in high temperature environments; The lower furnace body

- Q: What kinds of refractory materials that uses a-Al2o3 powder? What are the purpose of it?

- 04La-Al2O3 powder is a alumina powder whose raw material is industrial aluminum oxide which has been calcined at high temperature. It is a good polishes for ceramics and jade, meanwhile, it is also an important raw material for high-end refractory materials. The technical indicators parameters A1023 mark A1535 chemical composition AL2O3≥ 99.92 3%, ≥ 3.10FE203≤ 0.799 Refractory calcined alumina powder (a-Al2O3) 1.2 true density (g & # 47, by fully ground powder made of different fineness .O.10 0.07 0.04NA2O≤ 0.93a-Al2O3 (%) ≥ 95 95 primary crystallization average grain (um) 2 ~ 3 3 ~ 5 average particle size (um) 40 ~ 602.6SIO2≤ 0.1 0.15B2O3≤ - 0, glass, engineering ceramics typical use electronic ceramic insulating ceramic refractory ceramic wear 3

- Q: About the use of horseshoe glass kiln refractories

- the lower portion of advanced clay brick, the lower portion of magnesia-chrome brick arch - high-purity silica brick; flue - clay brick; breast wall--33 # fused zirconia corundum brick (with shrinkage); fused zirconia bottom --33 # fused zirconia corundum brick (with shrinkage); regenerative chamber- the upper part of sintered magnesia-chrome brick, cooling section 33 # electric?smelting no shrinkage fused zirconia corundum brick; the wall - the melting section 41 # no shrinkage fused zirconia corundum brick (including 41% of zirconium; the lattice- superstructure of high purity magnesia brick, the same below); small stove --33 # fused zirconia corundum brick (with shrinkage). It can be said that it is the maximum configuration, if the funds is limited it can be downshift appropriately.

Send your message to us

Raw Materials for Refractory:Natural Flake Graphite FC 89 with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords