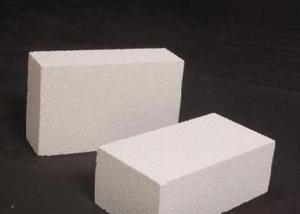

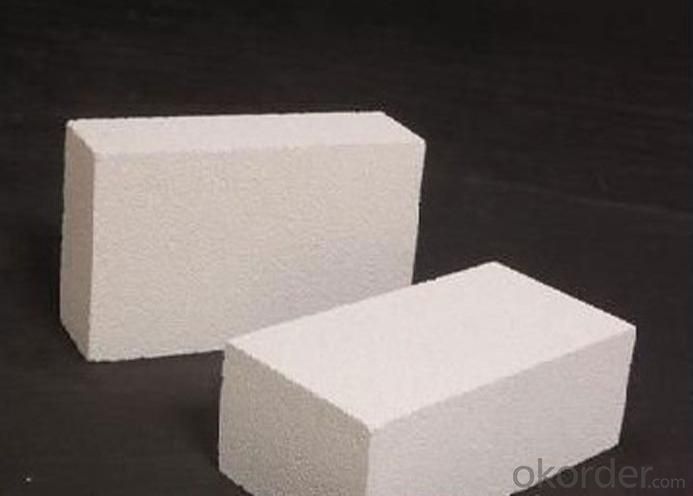

Refractory JM Mullite Insulation Brick in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month furnace bricks refractory material standard size in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of Refractory JM Mullite Insulation Brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Description of Refractory JM Mullite Insulation Brick

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application of Refractory JM Mullite Insulation Brick

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Sunrise Brand |

JM23 |

JM26 |

JM28 |

JM30 |

JM32 | |

Classification Temperature (°C) |

1260 |

1430 |

1540 |

1650 |

1760 | |

Bulk Density (g/cm3) |

0.55-0.60 |

0.78 |

0.88 |

1.03 |

1.25 | |

Cold Crushing Strength (Mpa) |

1.2 |

1.6 |

2.1 |

2.5 |

3.5 | |

Modulus of Rupture (Mpa) |

0.9 |

1.4 |

1.6 |

2.1 |

2.1 | |

Reheating Linear Change (%)

CT-30 °CX 8H |

1230°C

-0.5 |

1400°C

-0.5 |

1510°C

-0.5 |

1620°C

-0.9 |

1730°C

-0.9 | |

Thermal Expansion

1000°C(%) |

0.5 |

0.7 |

0.8 |

0.9 |

1.1 | |

Thermal conductivity(W/m.k) |

400°C |

0.14 |

0.27 |

0.32 |

0.41 |

0.49 |

600°C |

0.16 |

0.29 |

0.34 |

0.43 |

0.5 | |

800°C |

0.18 |

0.31 |

0.36 |

0.44 |

0.51 | |

1000°C |

0.20 |

0.33 |

0.38 |

0.45 |

0.53 | |

Al2O3 (%) |

37 |

58 |

67 |

73 |

77 | |

Fe2O3 (%) |

1.0 |

1.0 |

1.0 |

0.5 |

0.4 | |

- Q: what is the best cement to fix cracks on cool decking

- You can buy cartridges of cement like stuff for small cracks. When you say cool decking do you mean temperature or style. I'm assuming temperature. If the cracks are bigger you can get premixed in buckets. What is the best? Cement is cement any crack you fill will have to be refilled. New cement does not stick well to old dry cement. They do make plastic fillers, my landscaper used it for grout in the patio, that has held up real well over the years. You may want to try that. Got to Lowes or HD and talk to the people there for details.

- Q: In a CSI episode, a guy filled his letter box with cement because his letter box was getting destroyed every night. He had 4 destroyed, had enough and decided to fill the next one with cement. What happened was two guys drove past with a bat, the guy swung to hit the letter box but because it went wrong they crashed and died. The owner buried the letter box, replaced it but of course the CSI team figured it out...and he was arrested. What was the crime he committed? I mean, he had to pay for the replacements so why is he being punished for trying to protect his property? He didn't mean the boys any harm, he was just trying to save his letterbox...

- The premise is, the cement mailbox was intended to cause harm to the guys with bats. His intent to cause harm to them, no matter how small, led to their death. Therefore, his actions ultimately led to their death, making it his fault. Its the real thing. Any action you take that is grossly negligent can land you in deep trouble, no matter what your true intentions were. Same premise, different scenario: How about a simple fight at school? You know, just a couple guys throwing a few punches. Well, one idiot catches a blow to the jaw and drops onto the ground, smashing his head and corner of something/anything. He dies from the head injury, that resulted from fall that resulted from the punch. The guy that simply punched him just ate a murder charge.

- Q: can you use cement in ceramic molds?

- I dont think so. As it dries the cement will expand and could damage or destroy the mold. Secondly I dont know how well the cement would react to a release agent in such a mold.

- Q: coal fly ash % used in cement?

- You can specify any amout of fly ash you want. The fly ash is cheeper that other compounds so it makes the mix cheeper. Too much will hurt the strength.

- Q: The Now building materials business to do it, including what aspects?

- Building materials are commonly used in civil engineering and construction materials. Can be divided into structural materials, decorative materials and some special materials. Structural materials include wood, bamboo, stone, cement, concrete, metal, brick, ceramic, glass, engineering plastics, composite materials, etc .; decorative materials, including a variety of coatings, paint, coating, veneer, colored tiles, with special effects Glass, etc .; special materials that used for waterproof, moisture, corrosion, fire, fire, noise, insulation, insulation, sealing and so on. Now building materials business is not good to do.

- Q: I want to stain my cement/concrete patio around my pool. What is the best stain to use. I don't want to have to keep redoing it every year.

- This site will give you all the information you need to make an informed decision

- Q: difference between 53grade and 43graade cement?

- The OPC(Ordinary Portland Cement) was classified into three grades, namely 33 grade, 43 grade and53 grade depending upon the strength of the cement at 28 days when tested as per IS 4031-1988. If the 28 days strength is not less than 33N/mm2, it is called 33 grade cement, if the strength is not less than 43N/mm2, it is called 43 grade cement, and if the strength is not less than 53 N/mm2, it is called 53 grade cement

- Q: Quick question which is what is water Putty and Portland cement used for and back...way back in the day what was it used for?

- Water putty is a putty that will harden even if it is underwater. You would usually use it repairs under water. Pools, pipes, ETC Portland cement is used to make concrete. Concrete usually has the cement and some type of hard particles ( sand, small rocks, or both)

- Q: I would like to do building cement business, there are also sales in this area, I would like to ask this is not a lot of money is also a lot of money. In the sales side of this relationship has a relationship between the Department of the production of a large real estate company, I would like to have no problem and then there is a commodity concrete company. I would like to ask if this is not a lot of money to pay the money will be very powerful. More

- This is to see your working capital,Selling fast, money back fast, hundreds of thousands is enough.

- Q: what is the differance between concrete & cement ?

- Hi Martina. The difference between concrete and cement. Cement is used to stick bricks together like in houses. Concrete is used to make roads, foundations for houses. and large concrete structures. Concrete has the added benefit of using ballast (ie) small stones for added strength. for strength reinforcing bars are also added. Lorna.

1. Manufacturer Overview

| Location | Luoyang, China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Eastern Europe; Southeast Asia; Mid East; Eastern Asia; Northern Europe; Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory JM Mullite Insulation Brick in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month furnace bricks refractory material standard size in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords