Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

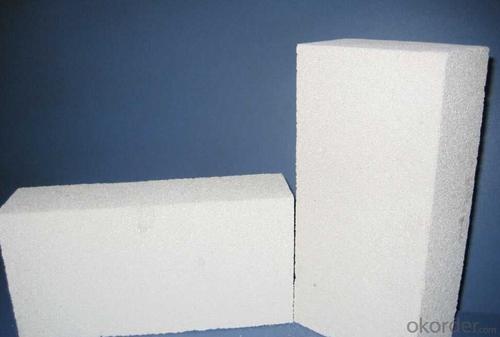

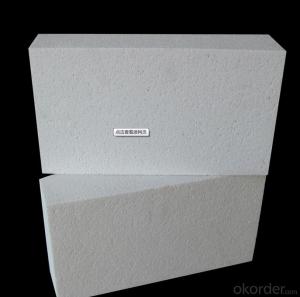

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

Refractory GJM Mullite Insulation Brick B-4

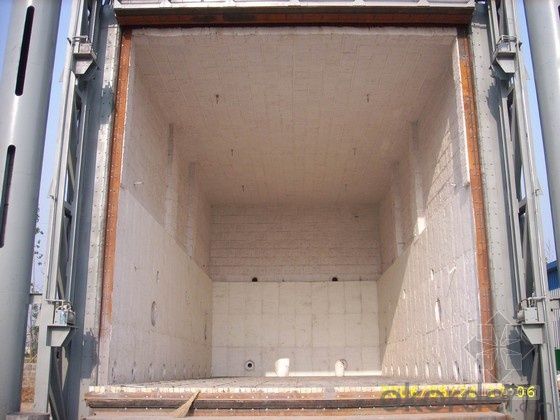

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Refractory GJM Mullite Insulation Brick B-4

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-4

- Q: Are insulating fire bricks resistant to thermal fatigue?

- Insulating fire bricks are indeed resistant to thermal fatigue. These bricks are specifically designed to withstand high temperatures and thermal cycling without cracking or breaking. They are made from refractory materials that have excellent thermal shock resistance, allowing them to expand and contract without any significant damage. This resistance to thermal fatigue makes insulating fire bricks ideal for applications that involve extreme temperature variations, such as in kilns, furnaces, and other high-temperature environments.

- Q: Can insulating fire bricks be used in the construction of industrial boilers?

- Yes, insulating fire bricks can be used in the construction of industrial boilers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in boiler systems where heat retention and efficiency are crucial. They help to prevent heat loss and ensure efficient energy transfer, making them a popular choice for industrial boiler applications.

- Q: Can insulating fire bricks be cut to custom sizes?

- Yes, insulating fire bricks can be cut to custom sizes. Insulating fire bricks are typically made from lightweight materials such as ceramic fibers or lightweight aggregates, which make them relatively easy to cut. They can be cut using various tools such as a saw, knife, or specialized cutting equipment. It is important to take proper safety precautions and use appropriate tools and techniques to ensure a clean and accurate cut. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure that the cutting process does not compromise the integrity or thermal properties of the insulating fire bricks.

- Q: How do insulating fire bricks compare to other insulation materials?

- Insulating fire bricks are highly effective insulation materials that offer several advantages over other insulation materials. First and foremost, insulating fire bricks have excellent thermal properties, meaning they can efficiently prevent the transfer of heat. They have a low thermal conductivity, which allows them to effectively insulate against high temperatures. This makes them ideal for use in applications where heat retention is crucial, such as furnaces, kilns, and fireplaces. Compared to other insulation materials like fiberglass or mineral wool, insulating fire bricks are much more durable and long-lasting. They can withstand extremely high temperatures without losing their insulating properties or structural integrity. This durability makes them a cost-effective choice since they require less frequent replacement. Another advantage of insulating fire bricks is their ability to resist chemical attack and wear. They are resistant to acids, alkalis, and other corrosive substances, making them suitable for applications involving harsh chemicals or environments. Furthermore, insulating fire bricks have a high compressive strength, allowing them to bear heavy loads without cracking or breaking. This makes them suitable for use in structural applications where weight-bearing capacity is essential. In terms of installation, insulating fire bricks are easy to work with. They can be cut, shaped, and installed using basic tools, allowing for customization and flexibility in different applications. They are also lightweight, which simplifies the installation process and reduces the overall weight of the structure. Overall, insulating fire bricks offer superior insulation properties, durability, resistance to chemicals, and ease of installation compared to other insulation materials. Their ability to withstand high temperatures, resist wear and tear, and provide long-lasting insulation make them an excellent choice in various industrial and domestic settings.

- Q: Can insulating fire bricks be used in the construction of heat storage systems?

- Yes, insulating fire bricks can be used in the construction of heat storage systems. Insulating fire bricks are designed to have low thermal conductivity, which means they are capable of trapping and storing heat effectively. These bricks are made from materials such as fire clay, which have excellent insulation properties. By using insulating fire bricks, heat loss can be minimized, allowing for efficient heat storage and retention in heat storage systems. The bricks can be used to build the walls and lining of the heat storage system, ensuring that the stored heat is not dissipated to the surroundings. Additionally, insulating fire bricks are lightweight and easy to handle, making them a convenient choice for constructing heat storage systems. Overall, the use of insulating fire bricks in the construction of heat storage systems enhances their thermal efficiency and contributes to more effective heat management.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- No, insulating fire bricks cannot be used in ceramic fiber blankets. Insulating fire bricks are solid and rigid, while ceramic fiber blankets are flexible and designed for insulation purposes. They serve different functions and have different properties, making them incompatible for use together.

- Q: What are the bubble bricks?

- The requirements for production conditions are not high. Simple shed to plant products without open storage, warehouse, on the quality of workers is not high.

- Q: Can insulating fire bricks be used for insulation in power plants?

- Insulating fire bricks have proven themselves to be effective for insulation purposes in power plants. These bricks are specifically designed to possess exceptional thermal insulation properties, making them highly suitable for applications involving high temperatures. They can endure extreme temperatures and effectively insulate power plant operations, thus preventing heat loss and enhancing energy efficiency. In power plants, insulating fire bricks find extensive usage in various areas, including furnaces, boilers, kilns, and chimneys. They can be utilized to line the walls, floors, and roofs of these structures, aiming to minimize heat transfer and maintain optimal temperatures within the equipment. The utilization of insulating fire bricks in power plants offers numerous benefits. These bricks aid in reducing heat loss, enhancing combustion efficiency, and alleviating thermal stress on the equipment. They create a barrier against heat transfer, thereby conserving energy and minimizing operational expenses. Moreover, their insulation properties contribute to a safer working environment for power plant personnel. Nevertheless, it is important to exercise caution when selecting insulating fire bricks for power plant insulation. The specific requirements and conditions of the power plant should be carefully considered. Factors such as operating temperature, exposure to chemicals, and mechanical stress should be taken into account to ensure that the bricks are capable of withstanding harsh conditions and delivering long-lasting insulation performance.

- Q: Are insulating fire bricks suitable for high-temperature kilns?

- Yes, insulating fire bricks are suitable for high-temperature kilns. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in kilns that require high operating temperatures. These bricks are made from lightweight and porous materials, such as clay or silica, which have low thermal conductivity. This allows them to effectively trap heat within the kiln and prevent heat loss, while also providing insulation against the external environment. Additionally, insulating fire bricks have good resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. Overall, insulating fire bricks are a reliable and efficient choice for high-temperature kilns.

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Yes, insulating fire bricks can be used in wastewater treatment plants. They are often used in the construction of furnaces, kilns, and other high-temperature applications in these plants to provide thermal insulation and retain heat efficiently.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords