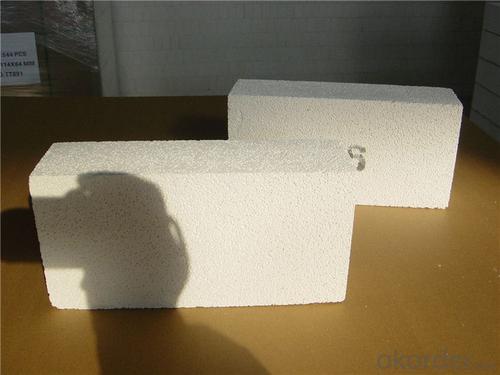

High Purity Insulating Fire Bricks - Refractory Clay Insulating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Insulating Fire Brick Technical index

Brand Quality | JM23 | JM26 | JM28 | JM30 | JM32 | |

Bulk Density (g/cm3) | 0.52 | 0.78 | 0.88 | 1.03 | 1.25 | |

1.2 | 1.6 | 2.1 | 2.5 | 3.5 | ||

Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

-0.5 | 1400℃ -0.4 | 1510℃ -0.5 | 1620℃ -0.9 | 1730℃ -0.9 | ||

Thermal Expansion 1100℃(%) |

0.5 |

0.7 |

0.8 |

0.9 |

1.1 | |

Thermal conductivity(W/m.k)

| 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.50 | |

800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

Al2O3 | 37 | 58 | 67 | 73 | 77 | |

Fe2O3 | 0.7 | 0.7 | 0.6 | 0.5 | 0.4 | |

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: Difference between inorganic insulation material and organic thermal insulation material

- The main difference between inorganic insulation materials and organic thermal insulation materials is that the types of insulation materials are different:1, inorganic insulation materials, including glass wool, rock wool, expansion perlite, micro nano insulation board;2, organic insulation materials are mainly polyurethane foam, polystyrene board, phenolic foam and so on.

- Q: What are the main components of insulating fire bricks?

- Insulating fire bricks usually consist of a blend of alumina, silica, and assorted lightweight additives. Alumina (Al2O3) is crucial in insulating fire bricks due to its ability to withstand high temperatures and resist thermal shock. Silica (SiO2) contributes to improving the refractory qualities and insulation abilities of the bricks. Furthermore, vermiculite or perlite, which are lightweight additives, are commonly incorporated to enhance the insulating properties of the bricks. The collaboration of these components produces a material that possesses exceptional thermal insulation, minimal thermal conductivity, and remarkable heat resistance.

- Q: Advantages and disadvantages of external formwork and self thermal insulation block

- Self insulation block first meet the requirements of national energy conservation, the outer template also meets the requirements, but the process is more complex, higher cost,Insulation block although the price is high, but does not appear to burst mode, collapse, internal cracking and other problems, while the internal insulation block can control the cracking problem, the difficulty of construction on the ratio of template to technology, can refer to and block construction!

- Q: Are insulating fire bricks resistant to oil and gas?

- Yes, insulating fire bricks are generally resistant to oil and gas. These bricks are designed to withstand high temperatures and are commonly used in applications where they may come into contact with oil and gas, such as furnaces and kilns. However, it is important to note that the specific type and composition of the fire bricks can affect their resistance, so it is always recommended to consult the manufacturer's specifications for detailed information.

- Q: Can insulating fire bricks be used in refractory linings for blast furnaces?

- Yes, insulating fire bricks can be used in refractory linings for blast furnaces. These bricks have high insulating properties, which help to reduce heat loss and improve energy efficiency in the furnace. Additionally, they offer good thermal shock resistance and can withstand the extreme temperatures and harsh conditions within the blast furnace.

- Q: Are insulating fire bricks resistant to gas permeation?

- Generally, insulating fire bricks exhibit resistance to gas permeation. They possess a low porosity design, minimizing open spaces for gas passage. This attribute renders them highly effective in preventing gas permeation. Moreover, insulating fire bricks are commonly constructed from materials like alumina, known for their exceptional resistance to high temperatures and chemical reactions. This further bolsters their resistance to gas permeation. In conclusion, insulating fire bricks are a dependable option for minimizing or preventing gas permeation in various applications.

- Q: Can insulating fire bricks be used in the construction of cremation chambers?

- Yes, insulating fire bricks can be used in the construction of cremation chambers. These bricks are designed to withstand high temperatures and provide excellent insulation, which is crucial in maintaining the desired temperature and preventing heat loss during the cremation process.

- Q: Are insulating fire bricks suitable for insulation in gas turbines?

- Yes, insulating fire bricks are suitable for insulation in gas turbines. They have excellent insulating properties and can withstand high temperatures, making them an ideal choice for protecting and insulating the components of gas turbines.

- Q: Are insulating fire bricks resistant to water penetration?

- Insulating fire bricks exhibit resistance to water penetration. These bricks possess a low porosity and are fabricated from materials that do not readily absorb or retain water. Typically, they consist of lightweight refractory materials like alumina, silica, and other minerals that possess remarkable heat resistance and minimal water absorption capabilities. Consequently, insulating fire bricks are highly suitable for scenarios where water penetration could be detrimental, such as in high-temperature environments or when utilized as insulation in chimneys or kilns. However, it is essential to acknowledge that while these bricks resist water penetration, they are not entirely impervious to it. Prolonged exposure to water may eventually result in some degree of water absorption, which can impact their insulating properties. Therefore, it is prudent to exercise caution and ensure proper installation and maintenance to optimize their resistance against water penetration.

- Q: Can insulating fire bricks be used for pizza ovens?

- Yes, insulating fire bricks can be used for pizza ovens. Insulating fire bricks are designed to withstand high temperatures, making them a suitable choice for creating a well-insulated and efficient pizza oven. They help retain heat, allowing the oven to reach and maintain the desired temperature for baking delicious pizzas.

Send your message to us

High Purity Insulating Fire Bricks - Refractory Clay Insulating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords