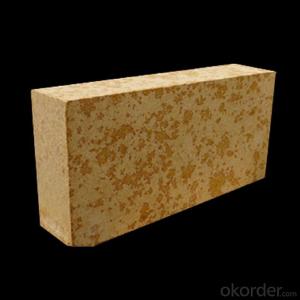

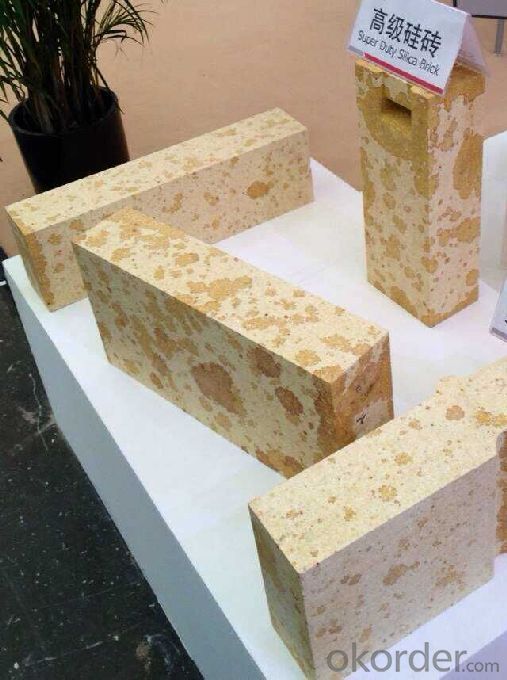

Raw Materials for Refractory Silicon Bricks Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q: What materials is silicious thermal insulation board made of?

- Refractories that contain more than 93% of the monox are acidic refractory materials which include ordinary silica brick, high-density and high-purity silica brick, silica brick that contains chromium, fused quartz products, unburned brick and siliceous ramming materials. It has good softening temperature under a fixed load and can resist corrosion of acid slag, but will have chemical reaction with alkaline slag. Silicious refractory of industrial value mainly is crystalline quartz, such as α and β quartz, tridymite and cristobalite.

- Q: What are the models of refractory cables?

- There are bout four types. 1.NA-YJV / NB-YJV Crosslinked polyethylene insulated PVC sheath A (B) class fire-resistant power cable 2.NA-YJV22 / NB-YJV22 Crosslinked polyethylene insulated steel belt braiding PVC sheath A (B) class fire-resistant power cable 3.WDNA-YJY / WDNB-YJY Crosslinked polyethylene insulated polyolefin sheath A (B) class low smoke no halogen fire retardant power cable 4.WDNA-YJY23 / WDNB-YJY23 Crosslinked polyethylene insulated steel belt braiding polyolefin sheath A (B) class low smoke no halogen fire retardant power cable

- Q: Why the refractories should be waterproof and wetproof

- It is necessary to like magnesium carbon, waterproof and wetproof is more important. There is a variety of refractory materials, in general, basic is defective, and wherein the binder and additives water will lose their effect, the relationship is not very high aluminum large amount of water determines how much of the performance after the hydration will affect the strength and high temperature performance ;; hydration & quot, just need a little package like magnesium and calcium-based product itself readily react with water to calcium oxide, magnesium, chromium is not all the material goods have waterproof ordinary bulk materials need to add water before use

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Solid wood logs are necessary. If it is the type of smoke free material, it will not be necessary. You'd better confirm it with the port of destination. Vietnam has the requirement to smoke

- Q: In entering fire door, which material does well?

- About this, I personally advice you to take a look at the building materials market, where will be many options and comparativity would be much better.

- Q: Refractory materials are needed for casting metallurgy.

- High quality refractory materials can not be separated from the process of smelting metal and casting moulding, because the quality of melting furnace, iron / steel ladle directly affect the chemical composition of the metal liquid, and exert irretrievable influence on comprehensive quality of castings. Classification of refractory materials used in foundry smelting process: refractory brick, siliceous brick, high alumina brick, corundum brick, magnesia brick, magnesia brick, magnesia carbon brick. Unshaped refractory materials: ramming material, castable, refractory cement, silica, magnesia, coating material and light insulation material etc.

- Q: Who knows about the fire endurance of grade C fire doors?

- The fire endurance of grade C fire doors is no less than 0.5 hours. As the key role of family fireproofing, fire doors is particularly important. It can be classified according to the fire endurance and thermal insulation performance: The fire endurance of grade A fire doors is not less than 1.5 hours; that of grade B fire doors is not less than 1.0 hours; and that of grade C fire doors is not less than 0.5 hours. We can choose in accordance with different needs, but commonly used fire doors are grade A and B fire doors now.

- Q: Who can tell me the properties and classification of insulating refractories?

- It is the chemical method. The chemical reaction in the brick making process to produce gas and method for obtaining a porous brick. Usually use chemical reactions such as carbonate and acid, metal powder with acid, caustic and aluminum. Chemical reactions can be used must be relatively slow and can control or mechanical disturbance will disappear bubble in an injection mold. If the reaction is too fast, adding inhibitors such as hydrogen peroxide and manganese dioxide. The fine powder material slurry mixed with reactant bubbles to obtain stable foam slurry injection model, after drying the firing. This method of making pure oxide insulating refractory products, its porosity can reach 55% ~ 75%.

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- Could you tell me the fire-resisting time of class B fire proof door?

- Q: What is glass furnace used high-grade refractory materials?

- It is said that building a furnace need 30 million? After the ignition, it can't be gone out. Only at the waste to maintenance?

Send your message to us

Raw Materials for Refractory Silicon Bricks Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords