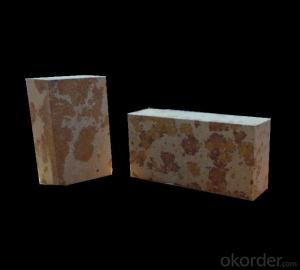

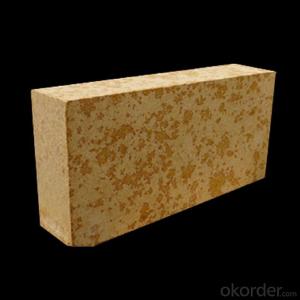

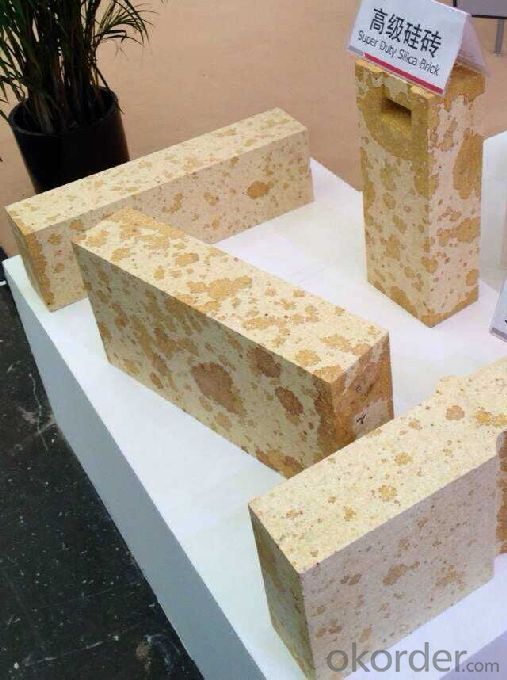

Raw Materials for Refractory Silica Brick Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q: For refractory, what is critical particle size? Thank you.

- It also refers to the largest particle size of aggregate!

- Q: What kind of material is good for cabinet fireproof board

- What kind of material is good for cabinet fireproof board What are the advantages and disadvantages of using it? How much is the price? A about how much does one piece cost?

- Q: Who can tell me about the foundry refractory materials?

- Such as: neutral, alkalic, acidic refractories. Of course, the raw materials of different materials are not the same. Such as: the magnesia-carbon bricks, basic refractory materials: magnesite(electric?smelting, high-purity)+ crystalline flake graphite+ phenolic resin+ additive (aluminate or silicon powder or silicon carbide powder or high-temperature pitch) and so on.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- The preparation of a report or statement. During the compilation process, any problems should be actively communicated with the construction side. For example, dust collector selection, environmental protection investment, total emission approval. (especially the total emission, you must let the construction side and communicate with the environmental protection bureau to get the total amount, otherwise you write the EIA does not make any sense.) Generally speaking, the preparation of the report is longer, about forty days; and the preparation of the report table is shorter, about fifteen days.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- 1. after roasting at high temperature of more than 1200 degrees, shale burned bricks in construction works can be free from expanding with heat and contracting with cold. 2. masonry walls can be plastered with no needs of any anti-cracking, reinforcement measures, and walls will not bulge and crack, which can reduce the construction cost, as well as are preferred building materials of frame structural engineering. 3.They have good sound insulation and thermal insulation performances, are one of the green building materials that the state currently promotes. 4. They have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance.

- Q: Is aluminium oxide refractory material?

- Calcination aluminium oxide is refractory material of fine performance made from pure aluminium oxide through high-temperature calcination. It can be made into coarse-grained material, fine-grained material, fine powder and micro powder, which can be made into pure jade burnt products. For example, corundum brick, lightweight corundum bricks. It can also be made into a variety of unburning products together with other materials, such as carbonaceous materials. For example, aluminum carbon and aluminium zirconium carbonaceous materials. As for the production of unshaped refractory material, there are more species. It can be corundum, rubing grain, corundum spinel and can also be added into other materials to improve specific performance. It isn't limited to high-alumina castable refractory and it can be castable refractory, ramming?mass, impressionable plastic material, gunning mix and refractory mortar.

- Q: Where do China and foreign countries do more refractory materials?

- The domestic production of refractory materials base in Henan Xinmi, Xinmi has a lot of production of refractory material factory, Zhengzhou gold refractories plant is relatively large, there is a need to go to visit the factory.

- Q: what are the types of piping insulation material fire?rating?

- Pipe insulation material Fire rating: heat conductivity coefficient(at room temperature) 0.025 grade non-combustible Class A low temperature bending ≤ 5000 breaking elongation 5,000 specifications 5000 anti-bending?strength 5000 compressive?strength 5000 special brand of high use temperature -250 ~ 150 ℃ core material, phenolic foam, form, stratiform, shape,flake.

- Q: What's the material of fireproof and wear-resisting floor?

- It is the kind of special concrete floor, and it should prevent from crash for it will produce fire by friction. It is mostly used for the warehouses storing explosive and inflammable objects and chemical materials. And its production process is the same with that of the common concrete floor, but it uses different material which needs to be the pebbles and sand after processing with marbles and dolomite.

- Q: What refractory materials are used in power plant

- Vacuum mud machine, sintering furnace! And then I will introduce some application of thermal material in power plant (below) I hope I can help you. Energy saving is the trend of future industrial development efforts, grinding machine, conveyor belt, so the production of light thermal insulation materials will gain state support, drying kiln. Our factory mainly produce light thermal insulation brick. The refractory material we use most is light insulation brick, and the equipment used is sand mixer (Luohe, Henan)

Send your message to us

Raw Materials for Refractory Silica Brick Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords