Quarter Inch Aluminum Sheets for Solar Reflector Reflective Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Reflective Strips for Solar Reflector

l Product Introduction

The Aluminum Strip is mainly used for refrigerator, cable ,capacitor shell material, steal-protection cover, cable sheathing, composite pipe and tube, water pipe etc. It has the property of deep drawing, high thickness accuracy, and low earring rate, etc.

l Features of aluminum strip

It has excellent thickness uniformity, slitting quality and high purity

1. PP metalized film have excellent self-healing performance

2. The selvedge is thickened, the PP metalized film welded performance is fine

3. the margin could be customized freely

4. The thickness of plate could be adjusted conveniently

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Strip has always been one of the most popular products in CNBM. With advanced technic skills and equipment, CNBM has produced high quality aluminium strips that meet international standard.

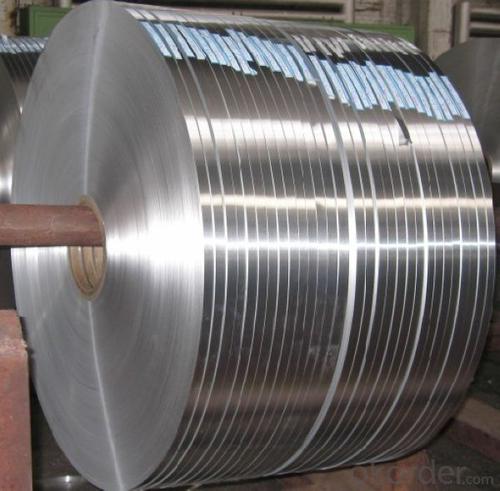

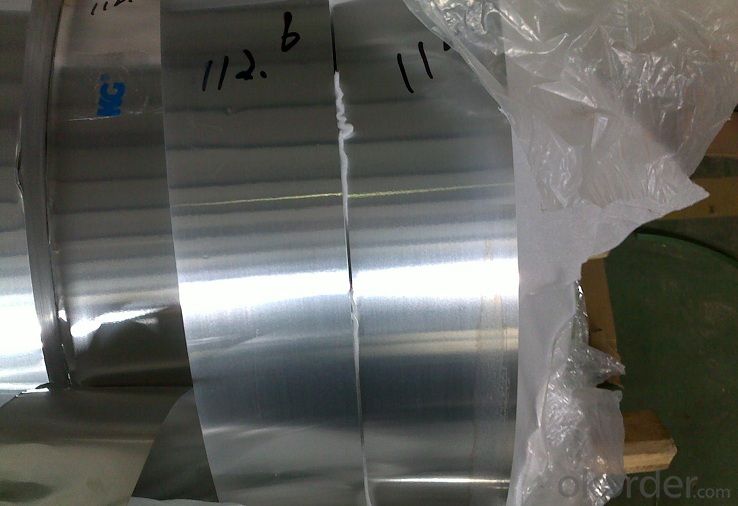

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: How does the thickness of aluminum sheet affect its formability?

- The thickness of an aluminum sheet directly affects its formability. Thinner sheets are generally more flexible and easier to bend or shape, making them more formable. On the other hand, thicker sheets are less malleable and require more force to bend or form, resulting in reduced formability.

- Q: What specific conditions or criteria need to be met when installing aluminum windows to ensure they are properly fitted and functional?

- <p>When installing aluminum windows, there are several special requirements to consider: ensuring the frames are level and square, using the correct size and type of fasteners, applying a proper sealant to prevent air and water infiltration, and adhering to local building codes. Additionally, it's crucial to check for thermal insulation properties, especially in areas with extreme weather conditions. The installation should also allow for proper drainage to prevent water damage. Professional installation is often recommended to meet these requirements and ensure the windows function correctly and last longer.</p>

- Q: 25mm thickness of hard aluminum processing to 6mm how to process, thank you all

- For a subject, use a saw. Can produce several, milling too wasteful.

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating.

- Q: Is it possible to use aluminum sheets for constructing car bodywork?

- <p>Yes, aluminum sheets can be used for car bodywork. They are known for their lightweight, corrosion resistance, and high strength-to-weight ratio, which makes them an ideal material for automotive applications. Aluminum is also recyclable and can contribute to the fuel efficiency of vehicles. It is commonly used in the manufacturing of car bodies, particularly in high-end and electric vehicles, for its durability and energy efficiency.</p>

- Q: Can aluminum sheets be used for storage tanks?

- Yes, aluminum sheets can be used for storage tanks. Aluminum is a lightweight, corrosion-resistant material that is commonly used in various industries, including storage tank manufacturing. It offers durability, excellent thermal conductivity, and is easily formable, making it suitable for storing various liquids and gases.

- Q: How do I join aluminum sheets together?

- To join aluminum sheets together, various methods can be utilized depending on the specific application and desired outcome. Here are several commonly employed techniques: 1. Riveting: Aluminum sheets can be joined by using rivets, which are small metal fasteners. This involves drilling holes in the sheets and then inserting the rivets, which are permanently secured by deforming or compressing them. Riveting is a widely used and durable method for joining aluminum sheets. 2. Welding: Aluminum welding can be accomplished through methods such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding. These techniques involve melting the aluminum at the joint, allowing it to fuse and create a strong bond upon cooling. Welding necessitates specialized equipment and expertise, but it provides a robust and permanent joining solution. 3. Adhesive bonding: This method employs industrial-grade adhesives specifically designed for bonding aluminum. The adhesive is applied to the surfaces to be joined, and then the sheets are pressed together and allowed to cure. Adhesive bonding results in a clean and aesthetically pleasing joint, although it may not be suitable for high-stress applications. 4. Mechanical fasteners: Another option for joining aluminum sheets is the use of screws, bolts, or nuts. This method entails drilling holes in the sheets and employing fasteners to secure them together. Mechanical fasteners offer a strong and adjustable joint, making disassembly easier if required. Before selecting a joining method, it is important to consider factors such as the strength requirements, appearance, ease of assembly, and disassembly of the application. Additionally, adhering to safety guidelines and seeking professional advice is essential if uncertainty or lack of experience with joining aluminum sheets exists.

- Q: According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- Well done on noting unexpected observations and following up. Your copper is coated with a dull coating of copper oxide. It became shiny because aluminium salts are acidic in water and the acidity dissolves the coating to form a copper salt and leaving the shiny copper. CuO + 2H3O+ ---- Cu2+ + 3H2O The reaction to form the acidity, a hydrated hydrogen ion H+(H2O) or H3O+ is fairly complex. If aluminium chloride is dissolved in a large amount of water the solution is acidic, but this has nothing to do with formation of hydrochloric acid. The solution contains hydrated aluminium ions and chloride ions: AlCl3(s) + aq → [Al(H2O)6]3+(aq) + 3Cl -(aq) The hexaqua complex ion behaves exactly like ions of similar type formed from transition metals; the small, highly charged metal ion polarises (withdraws electron density from) the water molecules that are attached to the aluminium ion through dative covalent bonds. This makes the hydrogen atoms d+ and susceptible to attack from solvent water, which is acting as a base. The complex ion is deprotonated, causing the solution to be acidic from the formation of hydroxonium ions H3O+: [Al(H2O)6]3+(aq) + H2O(l) → [Al(H2O)5OH]2+(aq) + H3O+(aq)

Send your message to us

Quarter Inch Aluminum Sheets for Solar Reflector Reflective Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords