Q235 Cold Rolled Steel Plate/ Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

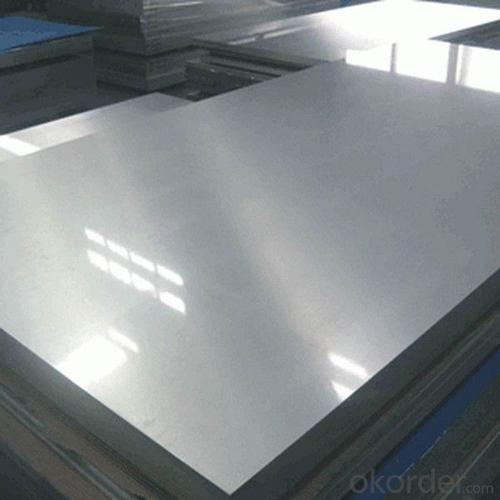

Q235 Cold Rolled Steel Plate

Product Description

Product name: Cold rolled steel plate

Product Description

.1)Thickness: 0.4-3.0mm

2)Width: 600/1000/1250/1500mm or customized

3)Grade: SPCC, SPCD, SPCE, DX51D+Z, DC01-06, ST12, 170P1, HC380LA, SPHC, Super deep drawing

4)Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

5)Weight of Cold Rolled Coil : 3-15MT

6)Surface Treatment: Galvanized or Oil

7)Technique: Cold rolled

8)Edge: Cut edge or Mill

9)Original place: Shandong, China

10)Advantage of Cold Rolled Coil :

High quality in flatness, brightness and straightness, and be qualified in both chemical compositions and mechanical properties.

11) Package of Cold Rolled Coil : Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

12)Applications for Cold Rolled Coil :(1) For the further producing of hot dip galvanized steel products or Prime Pre-painted Steel Coil

(2) Cold rolled Steel Coil: Auto manufacture, Oil drum, Transformer's tank panel, Furniture, bicycle, construction, battery case, industrial machine, etc.

13)Process of Cold Rolled Coil :

Pickling: To clean the dust and rust points on the surface.

Cold Rolling: Digital rolling control system produces minimum thickness tolerance, helps to prevent twist and improve straightness.

Slitting: Precise slitting machinery helps control the best width tolerance and avoid camber or cracker.

- Q: How do steel sheets perform in terms of vibration resistance?

- Due to their high stiffness and density, steel sheets generally exhibit excellent vibration resistance. The strong and rigid structure of steel enables it to effectively dampen vibrations, thereby enhancing its ability to resist a wide range of vibrations and minimize their amplification, a quality that is not found in other materials. Moreover, steel sheets can be further improved in terms of vibration resistance by employing techniques like incorporating damping materials or utilizing special coatings. As a result, steel sheets are widely regarded as a dependable option for applications that demand vibration resistance.

- Q: Are steel sheets suitable for roofing systems?

- Yes, steel sheets are suitable for roofing systems. Steel is a durable and long-lasting material that offers excellent protection against weather elements, such as rain, snow, and hail. It is also fire-resistant and can withstand high winds. Additionally, steel sheets are lightweight, making them easier to install and maintain.

- Q: Can steel sheets be used for manufacturing HVAC systems?

- Yes, steel sheets can be used for manufacturing HVAC systems. Steel is a common material choice due to its strength, durability, and thermal conductivity properties, making it suitable for constructing various components of HVAC systems such as ductwork, housing units, and heat exchangers.

- Q: What is the shelf life of steel sheets?

- The shelf life of steel sheets is typically considered to be indefinite. Unlike perishable goods, steel sheets do not have an expiration date or a limited lifespan. Properly stored and maintained steel sheets can remain in good condition for many years, if not decades, without any significant degradation. However, exposure to certain environmental factors such as moisture, extreme temperatures, and corrosive substances can affect the quality and durability of steel sheets over time. Therefore, it is recommended to store steel sheets in a dry and controlled environment to ensure their longevity and prevent any potential damage or deterioration.

- Q: Are steel sheets magnetic?

- Yes, steel sheets are magnetic.

- Q: How long do steel sheets typically last?

- Steel sheets typically have a lifespan of 20 to 30 years, although this can vary depending on factors such as the quality of the steel, maintenance, and exposure to environmental conditions.

- Q: How do steel sheets perform in terms of electrical conductivity?

- Steel sheets are not good conductors of electricity compared to materials like copper or aluminum. While steel does conduct electricity, it has a relatively high resistance, which limits its ability to efficiently transmit electrical current.

- Q: How are steel sheets protected during welding?

- Shielding plays a crucial role in safeguarding steel sheets during welding. Its purpose is to shield the sheets from oxygen and other atmospheric contaminants that can lead to oxidation and impurities in the weld. Multiple methods are utilized to shield the steel sheets during welding. One commonly employed approach involves using a shielding gas, such as argon or carbon dioxide, which is directed towards the welding area to establish a protective atmosphere. This gas displaces the surrounding oxygen, effectively preventing it from reacting with the heated metal and causing oxidation. In addition to the use of shielding gas, another widely used method involves employing flux. Prior to welding, a substance known as flux is applied to the joint area of the steel sheets. Acting as a protective barrier, the flux creates a molten slag that covers the weld and provides shielding from the atmosphere. Flux can take the form of a powder, paste, or even a continuous wire feed during welding. Furthermore, certain welding techniques, like submerged arc welding, combine the use of both shielding gas and flux to offer optimal protection for the steel sheets. This technique involves the continuous feeding of granular flux along with the welding wire. As the flux melts, it forms a protective layer over the weld, while the shielding gas effectively prevents any atmospheric contamination. Overall, the safeguarding of steel sheets during welding is crucial for ensuring the weld's quality and integrity. Shielding methods, such as the use of shielding gas and flux, establish a protective environment that prevents the formation of oxidation, impurities, and other defects in the weld. Consequently, this results in a robust and long-lasting joint between the steel sheets.

- Q: What is the width of carbon steel coil and the width of stainless steel coil, one is 1250 and the other is 1219?

- Domestic stainless steel rolling mill is generally 1219, but the design standard is 1300, so there will be flash board 1250, that is not the standard board, belonging to the flash, waste materials, many products manufacturers are also in 1219 as a reference size, product development, if the plate width will be wasted, a lot of scrap production the process, so the business order is generally around 1219 stainless steel coil.

- Q: Should the carbon fiber reinforce the steel bar on the side of the beam?

- Not necessarily, mainly depends on how the design is calculated, usually put 100~200mm carbon fiber layering

Send your message to us

Q235 Cold Rolled Steel Plate/ Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords