Brushed Aluminum Sheets Canada - PVDF Color Coating Aluminium Sheet for Sandwich Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PVDF Color Coating Aluminium Sheet for Sandwich Panels

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | 0.03MM-3.0MM |

WIDTH | 30mm-1700mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE ,PVDF , EPOXY,16-25MICRON PAINTING THICK, MAX 40MICRONS |

STANDARD | GB/T 17748-1999 |

2. Application of PVDF Color Coating Aluminium Sheet for Sandwich Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Color Coating Aluminium Sheet for Sandwich Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

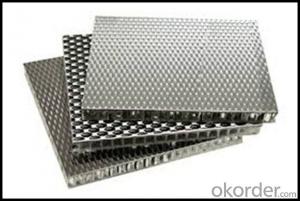

5. Image of PVDF Color Coating Aluminium Sheet for Sandwich Panels

6. Package and shipping of PVDF Color Coating Aluminium Sheet for Sandwich Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for a comparison between aluminum sheets and other types of sheet metal regarding their strength and durability.

- <p>Aluminum sheets are known for their high strength-to-weight ratio, making them lighter than many other sheet metals such as steel. They offer excellent corrosion resistance, which contributes to their durability. However, in terms of sheer strength, aluminum is not as strong as steel or titanium. Steel is stronger but also heavier, and while titanium is very strong and durable, it is also more expensive and less commonly used in construction and manufacturing. Aluminum's malleability allows it to be easily shaped and formed, and it is also non-magnetic and has good thermal conductivity. Overall, aluminum is a popular choice for applications requiring a balance between strength, weight, and resistance to corrosion.</p>

- Q: For my chem class that I just barely started taking, we're making bohr models. Even though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circles. I get everythign else about atoms except how they're actually made up lol. Maybe someone on here can explain it to me? I hope so because i have to make a model for it for friday.The element I'm asigned is aluminum btwYour help is greatly appreciated!

- Aluminum Bohr Model

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: Can aluminum sheets be used for reflective surfaces?

- Indeed, reflective surfaces can be crafted using aluminum sheets. Renowned for its exceptional reflectivity, aluminum proves to be an ideal material for producing such surfaces. With its sleek and impeccably polished texture, aluminum sheets efficiently bounce back light, heat, and various types of radiation. This remarkable attribute renders them suitable for an extensive array of purposes, encompassing solar panels, mirrors, lamp reflectors, and reflective insulation. Utilizing aluminum sheets as reflective surfaces offers numerous advantages, including their enduring nature, lightweight composition, and resistance to corrosion.

- Q: Are aluminum sheets suitable for electronics applications?

- Yes, aluminum sheets are suitable for electronics applications. Aluminum is a versatile and lightweight metal that offers excellent conductivity, making it an ideal choice for various electronic components and applications. Aluminum sheets are commonly used in the electronics industry for heat sinks, enclosures, PCB (printed circuit board) substrates, and connectors. Heat sinks made from aluminum sheets help dissipate heat generated by electronic devices, ensuring their optimal performance and preventing overheating. Additionally, aluminum sheets are often used as enclosures for electronic devices due to their durability, corrosion resistance, and ability to shield against electromagnetic interference. They provide a protective casing that ensures the safety and functionality of delicate electronic components. Aluminum sheets are also used as PCB substrates due to their excellent thermal conductivity. They help in dissipating heat generated by the electronic components on the PCB, preventing damage and ensuring the proper functioning of the circuit. Furthermore, aluminum is a cost-effective material compared to other metals commonly used in electronics, such as copper. This makes it a popular choice for various electronic applications, especially for mass production. In conclusion, aluminum sheets are highly suitable for electronics applications due to their conductivity, durability, corrosion resistance, and ability to dissipate heat. They offer numerous benefits and are widely used in the electronics industry for heat sinks, enclosures, PCB substrates, and connectors.

- Q: Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Yes, aluminum sheets are highly suitable for manufacturing aircraft interiors. Aluminum is a lightweight, yet strong and durable material, making it ideal for aerospace applications. Its high strength-to-weight ratio allows for the construction of lightweight and fuel-efficient aircraft. Aluminum sheets are also highly corrosion-resistant, which is crucial in the aerospace industry where aircraft interiors are exposed to various environmental factors such as humidity and temperature changes. This corrosion resistance ensures the longevity and reliability of the aircraft interior components, reducing maintenance and replacement costs. Furthermore, aluminum sheets can be easily fabricated and formed into various shapes, allowing for the production of complex and customized aircraft interior components. They can be easily cut, bent, and welded, offering design flexibility and enabling manufacturers to create sleek and aesthetically pleasing interior designs. In addition to these technical advantages, aluminum is also a sustainable material. It is 100% recyclable, making it an environmentally friendly choice for aircraft interiors. The recycling process requires significantly less energy compared to primary aluminum production, reducing the carbon footprint associated with manufacturing. Overall, the combination of its lightweight properties, corrosion resistance, ease of fabrication, and sustainability make aluminum sheets highly suitable for manufacturing aircraft interiors.

- Q: What are the different types of protective films available for aluminum sheets?

- There are several types of protective films available for aluminum sheets, including adhesive-backed films, peelable films, electrostatic films, and spray-on films. These films provide temporary protection against scratches, abrasions, and other damage during transportation, storage, and fabrication processes.

- Q: I am looking to purchase a pressure cooker and the size that i want comes in aluminum while alot of the others are made from stainless steel. I am wondering if the metal makes a difference in the funtionality and if one doesn't stand up as well as the other.

- This Site Might Help You. RE: Pressure cooker - aluminum vs. stainless steel? I am looking to purchase a pressure cooker and the size that i want comes in aluminum while alot of the others are made from stainless steel. I am wondering if the metal makes a difference in the funtionality and if one doesn't stand up as well as the other.

- Q: Can aluminum sheets be painted after installation?

- After installation, it is indeed possible to paint aluminum sheets. Aluminum, being a highly versatile and durable material, can be painted for the purpose of improving its appearance or harmonizing it with the surrounding environment. However, it is crucial to adequately prepare the surface before painting in order to ensure that the paint adheres well and lasts long. This typically involves cleaning the surface, eliminating any dirt or debris, and applying a suitable primer to enhance paint adhesion. Once the surface is prepared, various types of paint can be used on the aluminum sheet, such as acrylic, oil-based, or epoxy paint. To achieve the best results, it is advisable to seek guidance from a professional painter or carefully follow the instructions provided by the paint manufacturer.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- Simply put, 6061 and 6063 belong to the 6 series, 6061 hardness in 90HB 6063 in 80HB, suitable for brazing, surface oxidation treatment is better,

Send your message to us

Brushed Aluminum Sheets Canada - PVDF Color Coating Aluminium Sheet for Sandwich Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords