PVC Waterproofing Sheets with Polyester Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Sheets with Polyester Reinforcement

Product Description of PVC Waterproofing Sheets with Polyester Reinforcement:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproofing Sheets with Polyester Reinforcement:

1. Excellent anti-aging property.

2. Puncture- resistant.

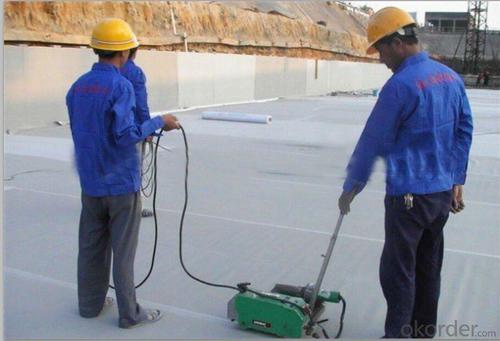

3. Welding construction,

4. High tensile strength, good elongation, good dimensional stability.

5. Good plasticity.

6. It has self-extinguishing from fire property.

7. Materials surface is smooth, fast color, stain resistance.

8. More wide, Wastage become less when being used.

Classification of PVC Waterproofing Sheets with Polyester Reinforcement:

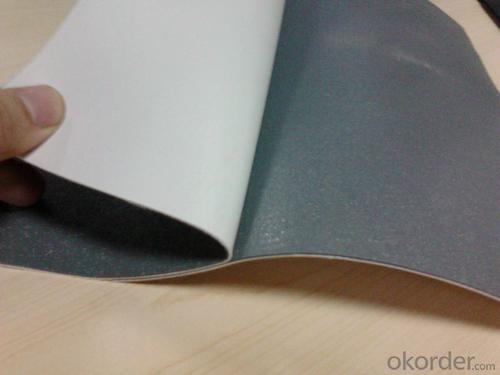

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Sheets with Polyester Reinforcement:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Sheets with Polyester Reinforcement:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Sheets with Polyester Reinforcement:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Images of PVC Waterproofing Sheets with Polyester Reinforcement:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are generally resistant to frost damage. Waterproofing membranes are designed to be durable and able to withstand various weather conditions, including freezing temperatures. They are typically made from materials such as modified bitumen, PVC, EPDM, or TPO, which have excellent resistance to frost and other environmental factors. These materials are engineered to remain flexible and elastic even in cold temperatures, ensuring that the waterproofing membrane remains intact and effective in preventing water penetration. Additionally, proper installation techniques and maintenance can further enhance the resistance of waterproofing membranes to frost damage.

- Q: Is a waterproofing membrane resistant to extreme weather conditions?

- Yes, a waterproofing membrane is designed to be resistant to extreme weather conditions. It provides a protective barrier against heavy rain, snow, and intense sunlight, ensuring that it remains intact and effective in preventing water infiltration and damage to the underlying structure.

- Q: Can a waterproofing membrane be applied on any surface?

- No, a waterproofing membrane cannot be applied on any surface. It is important to assess the suitability of the surface before applying a waterproofing membrane. The surface should be clean, structurally sound, and free from any contaminants that could hinder the adhesion of the membrane. Additionally, certain surfaces may require specific preparation or priming before the membrane can be applied effectively.

- Q: Can waterproofing membranes be used on foundation walls?

- Indeed, it is possible to utilize waterproofing membranes on foundation walls. These membranes possess a specific design that aims to impede the infiltration of water and are commonly employed on foundation walls to safeguard against moisture and water-related harm. Typically, these membranes consist of resilient materials like rubberized asphalt, thermoplastic, or PVC, which exhibit durability and resistance to water penetration. The installation of these membranes occurs on the outer side of the foundation walls, thereby serving as a highly efficient barrier against water, effectively averting its seepage into the basement or crawl space. Without a doubt, waterproofing membranes constitute an indispensable element in the realm of building construction, as they actively contribute to the preservation of the foundation's structural integrity, preventing adverse consequences such as water damage, mold growth, and foundation settlement.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. These requirements may vary depending on the type of membrane being used and the specific application. However, some general requirements include: 1. Surface Preparation: The surface where the membrane will be installed must be clean, dry, and free from any dust, debris, or contaminants. Any cracks or defects in the surface should be repaired prior to installation. 2. Adhesive or Bonding Agent: Depending on the type of membrane, an adhesive or bonding agent may be required to ensure proper adhesion to the substrate. This adhesive should be compatible with both the membrane and the substrate. 3. Primer: In some cases, a primer may be necessary to enhance the adhesion between the substrate and the membrane. The type of primer required will depend on the specific membrane and substrate being used. 4. Seam and Joint Preparation: Properly preparing seams and joints is crucial to ensure a watertight installation. This may involve using a specific sealant or tape to reinforce the seams and prevent water penetration. 5. Installation Techniques: The membrane should be installed according to the manufacturer's instructions and industry best practices. This may include using a specific method such as torching, hot air welding, or cold adhesive application. 6. Overlaps and Transitions: Properly overlapping the membrane sheets and ensuring smooth transitions between different areas is essential for a successful installation. This will help prevent water from seeping through gaps or weak points in the membrane. 7. Quality Control: Regular inspections and quality control measures should be implemented throughout the installation process to ensure that the membrane is being installed correctly and meets the required standards. It is important to consult the manufacturer's guidelines and specifications for the specific waterproofing membrane being used, as different membranes may have unique installation requirements. Additionally, local building codes and regulations should also be considered to ensure compliance and to meet any specific requirements in your area.

- Q: Can waterproofing membranes be used on plant rooms?

- Yes, waterproofing membranes can be used on plant rooms. Waterproofing membranes are often used in areas where water resistance is necessary, such as basements, roofs, and plant rooms. Plant rooms typically house various mechanical and electrical equipment, and using waterproofing membranes can help protect these sensitive components from water damage.

- Q: Does a waterproofing membrane require any protective coatings or sealants?

- In order to enhance its performance and durability, a waterproofing membrane typically needs some form of protective coatings or sealants. While the membrane itself provides waterproofing to some extent, it may not be enough to withstand all environmental conditions or potential damage. To create an extra barrier against water intrusion, UV radiation, mechanical stress, and chemical exposure, it is advisable to apply protective coatings or sealants on top of the membrane. These coatings or sealants also offer additional flexibility, strength, and protection against wear and tear. To determine the suitable type of coating or sealant for the specific membrane and project requirements, it is essential to seek advice from a professional waterproofing specialist.

- Q: Can a waterproofing membrane be used for roof gardens?

- Yes, a waterproofing membrane can be used for roof gardens. It is a common practice to use waterproofing membranes as a protective layer beneath the soil and plants in roof garden installations. These membranes help prevent water leakage into the building below and ensure the longevity of the roof garden system.

- Q: Can a waterproofing membrane be used in areas with chemical exposure?

- Yes, a waterproofing membrane can be used in areas with chemical exposure. However, it is important to select a waterproofing membrane that is specifically designed to withstand chemical exposure. Not all waterproofing membranes are created equal, and some may not be suitable for use in areas with chemical exposure. Chemical-resistant waterproofing membranes are typically made from materials such as polyurethane, epoxy, or polyurea, which are known for their resistance to various chemicals. These membranes are designed to provide a protective barrier against moisture and chemicals, preventing them from seeping into the underlying surfaces. When choosing a waterproofing membrane for areas with chemical exposure, it is crucial to consider the specific chemicals that will be present. Different chemicals can have different effects on materials, so it is essential to select a membrane that is specifically designed to resist the chemicals in the environment. Consulting with a professional or manufacturer is recommended to ensure the appropriate selection of a chemical-resistant waterproofing membrane for the specific application.

- Q: How does a waterproofing membrane handle movement or settling of the structure?

- A waterproofing membrane is designed to accommodate the movement or settling of a structure in a few different ways. Firstly, a waterproofing membrane is typically flexible and elastomeric, meaning it can stretch and move with the structure without cracking or tearing. This allows it to withstand minor shifts or settlements in the building without compromising its ability to keep water out. Additionally, some waterproofing membranes have built-in reinforcing materials, such as polyester or fiberglass, which provide added strength and durability. These reinforcements help the membrane resist potential damage caused by movement, settling, or even structural vibrations. Furthermore, many waterproofing systems include provisions for expansion joints or movement joints, which are intentionally created gaps or spaces in the structure to allow for natural movement. These joints are then sealed using flexible materials compatible with the waterproofing membrane. This allows the membrane to accommodate the anticipated movement or settling within these joints, preventing leaks or damage to the water barrier. In summary, a waterproofing membrane is designed to handle movement or settling of a structure by being flexible, elastomeric, and capable of stretching without tearing. Additionally, reinforcements and the incorporation of expansion joints further enhance the membrane's ability to accommodate movements and maintain its integrity as a waterproof barrier.

Send your message to us

PVC Waterproofing Sheets with Polyester Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords