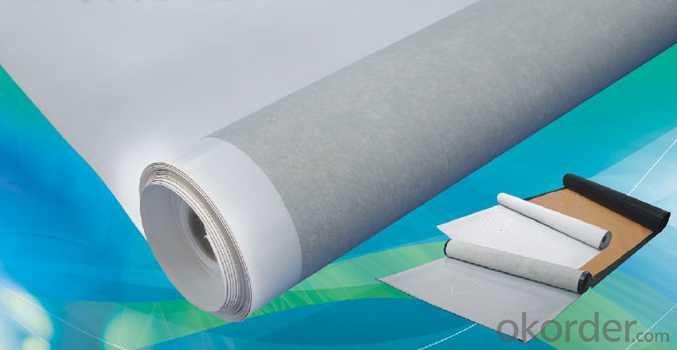

PVC Plastic Waterproof Membrane for Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of PVC Plastic Waterproof Membrane

High tension , perfect elongation ,perfect heating resistance .

Perfect jointing , It can be fused with base as a whole after heatingjointing .

High permeability ,chilling material and moisture can be expelled easily .

High aging resistance, UV resistance , corrosion resistance and erosion resistance .

Good cold flexibility (-20°C).

Service life can reach 50 years long with no pollution .

Surface can reflect UV .The temperature on the surface is low due to little absorbing heat.

Product features:

The physical and mechanical properties of stability, durability and anti ageing capacity is good, its oil and solvent resistance and general-purpose chloroprene rubber be roughly the same.

1 Good heat resistance, cold resistance, can be in (-60-150 C) within the scope of use.

2 Extension and rate very high tear strength, shrinkage cracking of buildings or a strong ability to adapt.

3 The proportion of light (0.90~0.97), the appearance of uniform quality, has good flexibility and elasticity.

4 Good weldability, materials can be directly welded, is conducive to ensure weld quality. After welding to form an integral waterproof layer.

5 Good dimensional stability, heat shrinkage is small, the deformation is small, keep a good state during construction.

6 Environmental protection type. Does not produce harmful substances in the production, construction and use of the process, and can be recycled, does not produce construction waste.

Specification of EPDM Waterproofing Membrane

1 | Breaking Tensile Strength(Room temperature) | Mpa | ≥7.5 | |

2 | Breaking Tensile Strength 60℃ | Mpa | ≥2.3 | |

3 | Breaking Elongation(Room temperature) | % | ≥450 | |

4 | Breaking Elongation(-20℃) | % | ≥200 | |

5 | Tearing strength | KN/m | ≥25 | |

6 | Impermeability, 30min no leakage | -- | 0.3Mpa no leakage | |

7 | Low temperature bending | ℃ | ≤ -40 | |

8 | Heating shrinking | Extension | mm | ≤2 |

Shrink | mm | ≤4 | ||

9 | Heat resistance (80℃x168h) | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥70 | ||

10 | Alkaline resistance, Ca(OH)2 solution, room temperature x168h | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥80 | ||

11 | Ozone aging(40℃x168h) | Elongation40%, 500x10-2 | -- | Non-crack |

12 | Synthetic aging | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥70 | ||

FAQ of EPDM Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Yes, a waterproofing membrane can be used on rubber surfaces. Waterproofing membranes are designed to create a barrier that prevents water from penetrating and damaging the underlying surface. Rubber surfaces, such as roofs, decks, or even rubber flooring, can benefit from the application of a waterproofing membrane to protect them from water damage. The membrane is typically applied as a liquid or a sheet, and it adheres to the rubber surface, forming a protective layer that prevents water from seeping through. This can help to extend the lifespan of the rubber surface and prevent issues such as leaks or decay caused by moisture. However, it is important to ensure that the waterproofing membrane is compatible with rubber and the specific type of rubber surface being treated, as some membranes may not adhere properly or may cause damage to certain types of rubber. It is always recommended to consult with a professional or the manufacturer of the waterproofing membrane to ensure proper application and compatibility.

- Q: Are waterproofing membranes resistant to chemical solvents?

- Yes, waterproofing membranes are generally resistant to chemical solvents. They are designed to provide a barrier against water and other liquids, including chemical solvents, to prevent leakage and damage to the underlying structure.

- Q: How does a waterproofing membrane handle differential settlement?

- A waterproofing membrane is designed to handle differential settlement by providing a flexible and durable barrier that can accommodate movement and prevent water penetration. It is capable of stretching and shifting along with the structure, ensuring that there are no gaps or cracks in the waterproofing system. This flexibility allows the membrane to adapt to any settling or movement of the building, effectively protecting it from potential water damage.

- Q: The difference between high polymer modified asphalt waterproofing membrane and sbs

- SBS modified asphalt waterproofing membrane is SBS rubber modified petroleum asphalt cited as the invasion coating, polyester fiber non-woven fabrics, jute cloth, fiberglass mats were made for the fetal base, the plastic film for the anti-sticking isolation Layer, by the selection, ingredients, eutectic, invasion, composite molding, curling and other processes processing production.

- Q: Can a waterproofing membrane be used in saunas?

- Yes, a waterproofing membrane can be used in saunas to protect the underlying structure from moisture and prevent water damage.

- Q: Are there any specific considerations for installing a waterproofing membrane on stucco surfaces?

- Yes, there are several specific considerations to keep in mind when installing a waterproofing membrane on stucco surfaces. Firstly, it is important to ensure that the stucco surface is clean and free of any dirt, debris, or loose material before applying the waterproofing membrane. This can be done by power washing or scrubbing the surface with a stiff brush and water. Secondly, it is crucial to choose the right type of waterproofing membrane that is suitable for stucco surfaces. There are various options available in the market, such as liquid-applied membranes, sheet membranes, or peel-and-stick membranes. It is essential to select a membrane that is compatible with stucco and provides a strong and durable barrier against water penetration. Another consideration is the proper application technique. The membrane should be applied evenly and smoothly, ensuring complete coverage over the entire stucco surface. It is important to follow the manufacturer's instructions and guidelines for the specific membrane being used. Additionally, it is recommended to pay attention to the details and transitions, such as around windows, doors, vents, or other penetrations. These areas are more prone to water infiltration, so it is important to properly seal and waterproof these vulnerable points using additional techniques or products, like flashing or caulking. Furthermore, it is essential to consider the climate and weather conditions in the area. If the stucco surface is exposed to extreme temperatures or frequent freeze-thaw cycles, it is advisable to choose a waterproofing membrane that can withstand these conditions and provide long-lasting protection. Lastly, regular inspection and maintenance of the waterproofing membrane is crucial to ensure its effectiveness over time. It is recommended to periodically check for any signs of damage, such as cracking, peeling, or bubbling, and promptly address any issues to prevent water infiltration and potential damage to the stucco surface. In conclusion, when installing a waterproofing membrane on stucco surfaces, it is important to clean the surface, choose the right type of membrane, apply it correctly, pay attention to details and transitions, consider the climate, and regularly inspect and maintain the membrane for long-lasting protection against water penetration.

- Q: Can waterproofing membranes be used on bridge decks?

- Yes, waterproofing membranes can be used on bridge decks. Bridge decks are constantly exposed to harsh weather conditions, including rain, snow, and freeze-thaw cycles, which can lead to the deterioration of the concrete and steel reinforcement. Waterproofing membranes are designed to prevent water infiltration and protect the bridge deck from moisture-related damage. These membranes are typically made of flexible materials such as bitumen, PVC, or EPDM rubber, and they are applied directly onto the bridge deck surface. The waterproofing membrane acts as a barrier, preventing water from seeping into the concrete and causing corrosion of the reinforcement. It also helps to reduce the formation of cracks and extends the service life of the bridge deck. Additionally, waterproofing membranes can be combined with other protective coatings or systems to enhance their effectiveness and durability. Overall, the use of waterproofing membranes on bridge decks is a common and effective method to ensure the long-term integrity and functionality of the structure.

- Q: Is a waterproofing membrane resistant to abrasion?

- A waterproofing membrane is generally able to resist abrasion. Its purpose is to create a protective barrier against water and moisture infiltration. These membranes are typically constructed from durable materials like PVC, TPO, or EPDM, which possess a high resistance to abrasion. Consequently, they can endure normal wear and tear that may arise during installation or due to foot traffic or other mechanical activities. Nonetheless, it is crucial to acknowledge that the level of resistance to abrasion can vary based on the specific type and quality of the membrane, as well as the conditions in which it is employed or utilized. Therefore, it is always advisable to refer to the manufacturer's guidelines and specifications to ensure the proper selection and installation of a waterproofing membrane.

- Q: Is a waterproofing membrane compatible with different types of flooring materials?

- Different types of flooring materials can be used with a waterproofing membrane. The purpose of a waterproofing membrane is to create a barrier between the subfloor and the flooring material, preventing moisture from causing any damage. This means that it can be used with laminate, vinyl, tile, and even hardwood flooring. By using a waterproofing membrane, the flooring material will remain protected from water damage, allowing it to last longer and maintain its appearance. However, it is important to keep in mind that specific compatibility requirements may exist for different types of waterproofing membranes. Therefore, it is advisable to consult the manufacturer's guidelines to ensure the proper installation of the chosen flooring material.

- Q: What is the resistance type SBS waterproofing membrane?

- The second is chemical resistance, in the waterproofing membrane production process, adding chemical resistance agent, similar to the chemical composition of herbicides, the plant roots are not close to the waterproofing membrane; In addition, copper ions have a similar effect.

Send your message to us

PVC Plastic Waterproof Membrane for Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords