PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

Machine Application

Such qualified extrusion line is mainly for producing PVC agricultural water/ building water/cable pipes, etc.

It can process various soft and rigid PVC, especially process powder directly into pipe shape.

Whole line consists of material feeder, conical twin screw extruder, die head, vacuum calibration tank, haul-off, cutter, stacker or belling machine, etc.

Machine List

| No. | Item | Qty |

| 1 | Screw feeder | 1 set |

| 2 | SJZ 80/156 Conical twin screw extruder | 1 set |

| 3 | Die head | 1 set |

| 4 | Vacuum calibration tank | 1 set |

| 5 | Three claws haul-off | 1 set |

| 6 | Planetary cutter | 1 set |

| 7 | Stacker | 1 set |

| Option | Belling Machine | 1 set |

Annotation: Some configuration and material can be designed according to customers’ requirement. | ||

Improvements made on Conical twin screw extruder:

1.Gear box bearings: NSK, Japan

2.Gear box: Jiangyin Brand

3.Special design of screw & barrel

4. All connector, nut etc all adopt nickel plated

Electrical part:

1. Solid state relay: Crydom, USA brand instead of common AC contacto

2. Siemens PLC controlling system

3. Pressure sensor: Dynisco,USA

4. Sayu cooling fan, Taiwan brand

5. ABB550 inverter

6. Siemens Beide motor

7. Low voltage component: Siemens/Schneider/LG

Corresponding Advantages:

1. Ensuring long-time stable operation & long service life

2. Compact structure, low noise, high bearing capacity, high transmission efficiency, ensuring long-time stable operation & long service life

3. Heating is controlled by Solid State Relay (S.S.R), realizing stable heating; (SSR) no spark & no noise improve safe production.

4. Siemens PLC controlling system with reliable technology, automatic and intelligent functions for centralized control and monitoring extrusion lines, which helps easy operation.

5. International brand of electronic parts guarantee stable operation and long service life.

Technical Data

Extruder | Pipe ranger (mm) | Max.output (kg/h) | Max.hauling speed (m/min.) | Extruder powder (KW) |

CAMX51/105 | 16-40 Dual | 120 | 10 | 18.5AC |

CAMX65/132 | 20-63 Dual | 250 | 15 | 37AC |

CAMX51/105 | 20-63 | 120 | 15 | 18.5AC |

CAMX65/132 | 50-160 | 250 | 8 | 37AC |

CAMX65/132 | 63-200 | 250 | 3.5 | 37AC |

CAMX80/156 | 160-315 | 350 | 3 | 55AC |

CAMX92/188 | 315-630 | 800 | 1.2 | 110DC |

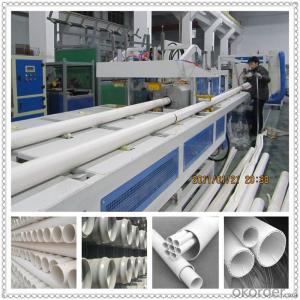

Product picture

FAQ:

Q: What price terms you offer?

A: FOB, CIF, EXW, L/C at sight and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Tangqiao Town, Zhangjiagang City, Jiangsu Province, China. About 2.5 hours from Shanghai Pudong International Ariport! We will arrange to pick you up from Shanghai.

A: Yes, our engineers will guide machine installation and train your workers.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: What raw material does the extruder use?

- An extruder in which an air vent is disposed at the center of an exhaust extruder to allow removal of air and volatiles from the processed plastic. The main machine of plastic extruder is plastic extruderIt consists of an extrusion system, a drive system and a heating and cooling system. 1. extrusion system extrusion system includes screw, cylinder extrusion die head, extrusion die head, molding parts of the extruder. Also known as extrusion die, extrusion die.

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Why single screw extruder is controlled by high school and low?

- What is controlled by high school? I can't answer the question without saying it

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: What should be paid attention to in the daily maintenance of the extruder?

- Extrusion machine regular maintenance mainly has these aspectsdrive system(1) check the temperature rise of motor and oil tank, whether the bearing is overheated locally, the abnormal noise of motor and gear, oil leakage, radial circle of oil filter and spline shaft, and the contact gap with the end of screw.(2) regularly clean the oil filter and remove the dirt at the bottom of the tank, and lubricate the lubrication points regularly.(3) the new gear box has been filled with gear oil, and new oil will be replaced every 4000 hours after the operation.

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- Advice from a professional perspective, if possible, suggest threading pipe equipment to do professional manufacturers buy, because now a lot of equipment is a two, a four, more advanced technology. Good luck!

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

Send your message to us

PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches