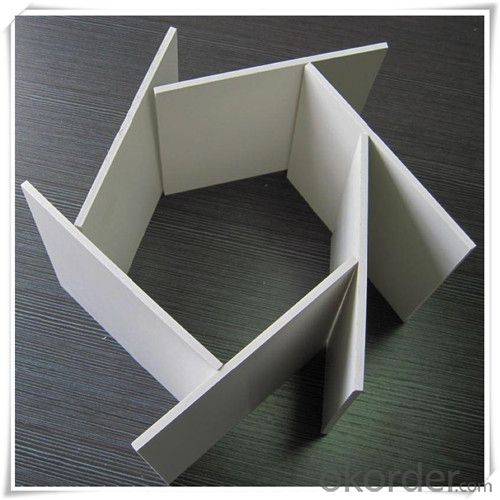

PVC Foam Sheet and PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PVC Foam Sheet Introduction:

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

Features:

1. Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

PVC Foam Sheet Details show:

Name | Density(g/cm3)±0.02 | width and length(mm) | Thickness(mm)±0.2 | Color |

PVC Foam Board | 0.8 | 1220*2440 | 1~25 | white,red, yellow, blue, green, gray, black |

0.6 | 2~25 | |||

0.5 | 2~25 | |||

0.8 | 1560*3050 | 1~10 | ||

0.6 | 2~10 | |||

0.7 | 2050*3050 | 1~10 | ||

pvc rigid sheet | 1.36-1.45 | 1220*2440 | 0.23-1.8 | |

2-5.8 |

Applications:

1. Advertising Signs, billboards, displays, exhibition stands

2. Screen printing, laser engraving

3. Thermoformed parts

4. Architecture, indoor and outdoor decoration

5. Furniture, kitchen & bathroom cabinet

6. Walls & partitions, wall cladding

7. Poolside furniture, swimming pool floor planking

8. Board for Chemical industry and laboratory equipment

9. Interior scaleboard for boat & ship, vehicle, train

Pictures:

FAQ:

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

- Q:Which plate is not easy to swell, mildew?

- Simi 3D laser board, edge strip and finishes 360 ° perfect package core board, the core of the super seal protection, so that water can be non-porous, greatly improve the moisture resistance of the plate to prevent the door due to long-term in the kitchen temperature and humidity The environment of water swelling and mildew, double cabinet life.

- Q:What is the material in the timber? What is the plate?

- The specifications of the material is the buyer's request to the wood processing into the required specifications such as 2 cm long 2 cm wide and 1 meter long and other special specifications, the buyer bought a little bit in the processing can be used, the plate is we often see the mountain wood processing Into a piece of one

- Q:What are the types of closet panels, there are several paint-free board?

- 1, solid wood: solid wood in a variety of wood 2, woodworking board to do: there is a woodless wood panels 3, fiberboard to do: that is, compression plate, can be made of paint-free 4, moisture board: can also be made of paint-free 5, ecological board: can also be made to promote the second type of paint.

- Q:What is the grade of the board?

- The country has not yet officially released on the E0 level of national standards, the current so-called E0 standard for the industry's most common convention. E0 means: less than or equal to 0.5 mg / l of formaldehyde emission E1 refers to: less than or equal to 9.0mg / 100g formaldehyde emission E2 means less than or equal to 30.0 mg / 100 g of formaldehyde emission

- Q:Plate furniture formaldehyde release national standard is

- Formaldehyde over the standard, then governance ah, you can carry out long-term ventilation, so that the air convection to the indoor harmful gases out of the room, you can also use some activated carbon and other physical adsorption, a lot of big leaves like formaldehyde plants like. But these are these to be long-term, not all of a sudden on the good governance. Want to quickly manage formaldehyde can be used ring Kang in addition to aldehyde enzyme ah, can quickly and effectively control the formaldehyde, benzene and other indoor harmful gases.

- Q:I went to the furniture market to see the production of furniture with a solid wood, the second is the plate. Solid wood is well understood, that plate is what, there are several? Which is better

- Generally divided into solid wood and man-made sheet. Solid wood is a natural solid wood sheet, this is easy to understand. Man-made sheet is divided into many categories. 1, multi-layer plywood. 2, Blockboard is the big core board. 3, high density board fiberboard (high density board) 4, solid wood particle board. 5, particleboard. 6, moisture board and so on

- Q:F grade sheet and EO-class plate, what is the difference between these two, Guiqiu master answer, buy a furniture to the market a question, really a headache? Which is good?

- These are the measures that measure the amount of formaldehyde released by the furniture and are environmentally friendly F4 star is a new upgrade of environmental standards, compared to E0 should be more advantages. ? The so-called F4 star standard, in fact, Japan's "F ☆ ☆ ☆ ☆ certification standard" F4 Star "is the highest standard of Japanese floor standards of health, but also considered the world's most healthy floor standards.If the usual E1, E0 Standard, then the "F3 star" is equivalent to the national E0 level standard, the proposed limit the use of area, "F4 star" is much higher than the "F3 star", the use of unlimited area. The standard applies to sheet, floor, Cabinets, furniture and other wooden building materials products.

- Q:What is the difference between acrylic and resin plates?

- Acrylic is the polymerization of PMMA produced by the polymerization of PMMA commonly known as polymethyl methacrylate, the use of pouring process, the domestic acrylic flat plate tolerance is relatively large, so if the design of the sandwich, the thickness must be more than 8MM, the plate is easy to deformation;

- Q:What is the material of the Margaret Wardrobe?

- Wardrobe board mainly granule board, solid wood, solid wood, etc., Margaret solid wood series do the best, low-key luxury, looks very high-grade, although a little expensive, but still very worthy of recommendation!

- Q:Calcium silicate board is what material

- Upstairs is copied over the calcium silicate board is a fiber cement products, you can understand that the main material is gypsum plaster, calcium silicate board main material is cement

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Sheet and PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords