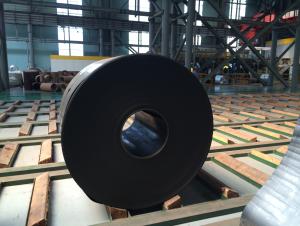

PRIME COLD ROLLED STEEL SHEET IN COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Grade:DC01 equivalent

Size | Width | Length | |

0.4 | 1000 or 1250 | COIL | |

0.5 | 1001 or 1250 | COIL | |

0.6 | 1002 or 1250 | COIL | |

0.7 | 1003 or 1250 | COIL | |

0.8 | 1004 or 1250 | COIL | |

0.9 | 1005 or 1250 | COIL | |

1 | 1006 or 1250 | COIL | |

1.25 | 1007 or 1250 | COIL | |

1.5 | 1008 or 1250 | COIL | |

1.8 | 1009 or 1250 | COIL | |

2 | 1010 or 1250 | COIL | |

|

|

|

COIL ID: 610MM

COIL WEIGHT: 12MTS MAX

PAYMENT: 100% LC AT SIGHT OR T/T 30% DOWNPAYMENT

SHIPMENT: 60 DAYS AFTER LC ISSUING DATE OR T/T DOWNPAYMENT

- Q: Home decoration what plate is good?

- Base plate material Willow eucalyptus wood for the decorative panel of the best material, most of the market are poplar core. How to determine is the willow wood floor? A kanban whether the warp deformation, whether vertical erection, the natural flattening or warping or plate is not tall and straight, can not be erected is a low-quality floor; two look at the weight of the floor, mostly large eucalyptus or other hardwood, light For the poplar; three look at the plate color, very uniform white or medium plate by dyeing cover the general treatment of poplar.

- Q: My family bought a cupboard made of melamine board these, a week or after the taste? These taste has no harm? Is there a methanol? Is it good to use these furniture?

- Melamine board, also known as double decorative panels, paint panels, ecological board, it was called a molding board. Its substrate is also particleboard and MDF, made by the substrate and the surface bonding, the surface veneer mainly domestic and imported two categories, because it is after the fire, anti-wear, waterproof soaking treatment, the use of results Similar to the composite wood flooring. Melamine decorative board performance: 1, can be any imitation of a variety of patterns, bright color, for a variety of wood-based panels and wood veneer, hardness, wear resistance, good heat resistance. 2, chemical resistance in general, can resist the general acid, alkali, grease and alcohol and other solvent wear. 3, the surface smooth and smooth, easy to maintain cleaning. Melamine board with natural wood can not both the excellent performance, it is often used for indoor construction and a variety of furniture, cabinets on the decoration. Melamine board is a wall decoration material. Some people use melamine board counterfeit flooring for floor decoration, which is not appropriate. Common specifications: 2440mm × 1220mm, thickness 1.5-1.8Cm.

- Q: Cabinet cabinet board plate 16mm and 18mm thickness What is the difference

- In fact, the plate is not the thickness of only 16MM only 3,6,9,12,15,18 you said 16MM is definitely posing as 18mm thick to buy you think T cut corners so powerful manufacturers can produce good things?

- Q: Kunming fly forest board and love grid plate which a good?

- Can these two be better than that? One is imported from Germany, one is Kunming, the core can see the gap

- Q: How to use a simple method to detect whether it is 316 stainless steel sheet

- You can also use the spectrometer, where you usually buy the goods

- Q: What is the difference between wood and wood?

- Wood can be called wood logs is the original length to the size, shape, quality standards or special provisions cut into a certain length of the wood section, the wood section called logs. Wood is processed semi-finished products. The use of wood: to be divided into direct use and chemical or special processing to do the use of raw materials. Wood direct use are: construction, pit wood, pillars, sleepers, packaging, furniture, craft sculpture, ships, sports equipment, cultural and educational supplies, musical instruments, decoration, grenade handle, butt, After chemical processing or special processing to do the use of raw materials are: paper, rayon, regenerated cellulose, nitrocellulose, cellulose acetate, ethyl cellulose, hydroxy cellulose, phenyl cellulose.

- Q: With self-tapping or what ,,,, solve, six meters wide and two meters of the door can be installed on the ground in the installation of the door?

- Can not be made in the above. There may be decomposition on the ground production Points up and down, and then to the above to fight together. Separate can not use self-tapping, after all, there is weight. Be sure to weld

- Q: Meet the ROHS standard PCB board which?

- Pmma is in line with the ROSH standard but you are not used

- Q: My family smokers next to the installation of a natural gas using a firearm, the two appliances exhaust pipe close to the natural gas company in the safety inspection that is very dangerous, between the two exhaust pipe to use the same fire with fire Of the plate, but I do not know which type of plate to use, please know the answer. I am good to buy

- Paper gypsum board paper. Gypsum board is a gypsum paste for the sandwich, both sides of the paper for the face of a light plate. Paper gypsum board texture light, high strength, fire, moth, easy to process. Plain gypsum board for interior walls, partitions and ceilings. After the fire treatment of water-resistant plaster board can be used for the humidity of the room walls, such as the bathroom, kitchen, bathroom and other tiles, metal plate, plastic tile wall lining.

- Q: There is the cloakroom between those hardware is not a fixed size of what? Help you heroes

- Solid wood finger plate Refers to the board, also known as integrated board, Glulam, refers to the material, that is, after the deep processing of solid wood small pieces like "fingers" stitching the same plate, due to the use of jagged wood between the board, similar to the fingers Cross-docking, so called the board. As the wood between the cross is a combination of such a combination of the structure itself has a certain binding force, but also because there is no need to stick up and down the surface of the panel, Gu its use of the plastic extremely small. Advantages: due to the connection of solid wood panels less, with less glue, so the environmental protection coefficient relative Higher. With easy processing, cutting, drilling, sawing and forming processing. Disadvantages: solid wood finger plate easy to deformation, cracking. Good solid wood finger board quality is guaranteed but the cost is higher. 5. Multi-layer solid wood board Multi-layer solid wood board to criss-crossing the multi-layer plywood as the substrate, the surface of high-quality solid wood paste or technology wood for the fabric, the cold, hot, sanding, health and other processes made of several processes. As a result of multi-layer solid wood board is not easy to deformation characteristics and good regulation of indoor temperature and humidity of the excellent performance, surface solid wood paste leather material and natural wood texture and feel, so more selective. Therefore, much consumers of all ages. Multi-layer solid wood board with good structural stability, not easy to deformation. As the vertical and horizontal gluing, high temperature and high pressure, from the internal stress to solve the deformation of solid wood defects. In the production process using self-made high-quality environmental protection glue (corn starch), so that the product limit of formaldehyde release to meet national standards, green.

Send your message to us

PRIME COLD ROLLED STEEL SHEET IN COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords