EASY-CLEANING PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

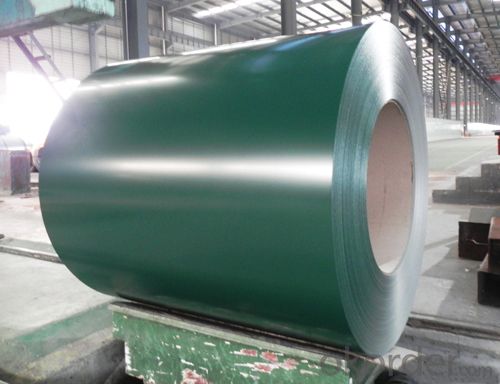

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:What are the types of plates for office furniture?

- Office furniture, the classification of the board are generally similar, the specific are divided into five points, but in order to understand its essence or need to learn slowly. 1, solid wood board As the name suggests, solid wood is made of complete wood made of wood. These plates are rugged, natural lines, is the best choice in the decoration. However, due to the high cost of such plates, and the construction process requires high, but not much use in the decoration. Solid wood panels are generally classified according to the physical name of the plate, there is no uniform standard specifications. At present, in addition to the floor and doors will use solid wood, the general use of our plates are manually processed out of the wood-based panels. 2, plywood ?Plywood, also known as plywood, line known as fine core board. Made of three or more layers of one millimeter thick veneer or sheet adhesive. Is the most commonly used furniture handmade furniture. Plywood is generally divided into 3 PCT board, 5 PCT board, 9 PCT board, 12 PCT board, 15 PCT board and 18 PCT board six specifications (1 PCT is 1mm). 3, decorative panel decorative panels, commonly known as panel. Is the solid wood board precision cut into a thickness of about 0.2mm meager veneer to the splint as the substrate, made by the adhesive process made with a single decorative effect of the decorative plate. It is a special way of plywood existence, with a thickness of 3%.

- Q:Look at the brand of wardrobe quite nice but offer too high. So I would like to buy their own plate to find wood workers to do. What sheet is good?

- Plate, you can use blockboard, or integrated board, now the integrated board, do a good look, and the logs feel good, backplane, you can choose camphor, you can also moth. The The Also need to draw rail, nails, rods and the like hardware

- Q:Giant peak sheet in the end okay?

- Plate can also, good quality, affordable and affordable. Usually made of standard size flat rectangular building material board, as a wall, ceiling or floor components. Also refers to the forging, rolling or casting made of metal plate. Divided into thin plate, medium plate, thick plate, special thick plate, usually made of standard size flat rectangular building material board. Plate product shape flat, thick and thick ratio, the unit volume of the surface area is also great, this shape features to bring its use on the characteristics: (1) large surface area, so inclusive capacity, in the chemical industry, containers, construction, metal products, metal structures, etc. have been widely used; (2) can be arbitrarily tailored, bending, stamping, welding, made of various product components, the use of flexible and convenient, in the automotive, aviation, shipbuilding and tractor manufacturing and other departments occupy an extremely important position; (3) can be bent, welded into various types of complex sections of steel, steel, large I-beam, channel and other structural parts, it is called "universal steel."

- Q:How is the environmental standard of the plate defined?

- Generally this is: 1.E2 grade refers to the formaldehyde content of less than or equal to 30mg / 100g 2.E1 grade refers to the formaldehyde content is less than dengyu89 mg / 100g (our standard) 3.E0 grade refers to the formaldehyde content of less than or equal to 5 mg / 100g. (European standard)

- Q:Many types of flooring, which OKorder is suitable for several floor plate?

- Ficus aurantium, Indian eggplant, ash wood, round beans, two wings beans, oak (white oak) Pineapple (small pineapple) Features: heavy, relatively hard. Stability is very good. Affordable choice. Description: The color of dark reddish brown wood, texture dense and strong, with curved curved black wood texture, the island people often used to make piling boat keel and semi-circular bracket. Wood adhering to the fine characteristics of pineapple grid, is a can be used for geothermal and has a variety of color selection of subtropical wood species. Is the ideal alternative to pineapple grid, also known as small pineapple grid. On behalf of the brand: Kyrgyzstan (mid-range), Huaming (old brand of good service), Li Feng (first-line brand) Merlin wood features: heavy, more hard wear, anti-termite moisture. Stability is very good, are cost-effective species, once popular. Indonesia to reduce the cutting prices have an upward trend. Brief introduction: 1, Indian eggplant is growing in the paradise rain forest in the precious tropical hardwood, it takes 80 years to mature, in each hectare virgin forest can only find 1-5 trees.

- Q:How to buy plate formaldehyde climate chamber?

- Buy formaldehyde climate box to focus on the following aspects: ????? 1, to find professional R & D manufacturers to buy, more than a few comparison, assessment of comprehensive strength! ????? 2, test box test parameters and test environment to meet the relevant standards and parameters! ????? 3, combined with their own products, choose the appropriate test space! ????? 4, formaldehyde climate test chamber should have a sophisticated test mode and improve the structure and security system! ????? 5, the price is better! A variety of configurations should be genuine to ensure the use of quality! ????? Combined with formaldehyde self-test characteristics of the proposed reference Zhengbang Detection Equipment Co., Ltd. Furniture formaldehyde test technology:

- Q:The most commonly used gas shielded welding consumables are certainly different from the material being welded. The silicon content and the manganese content in the wire are higher than those in the material. And the sulfur content inside the wire is much lower than the sulfur content of the base material being welded. Here, the role of silicon manganese is in the welding arc, in the welding bath for deoxidation of the chemical reaction, the other silicon manganese infiltration of the base metal can also improve the strength and plastic of the weld metal.

- 1, in most cases, sheet material and welding material is certainly not the same, the two are not comparable. 2, the plate is usually made of standard size flat rectangular building material board, for walls, ceilings or floor components. Also refers to the forging, rolling or casting made of metal plate. Divided into thin plate, medium plate, thick plate, special thick plate, usually made of standard size flat rectangular building material board. 3, the wire is used as a filler metal or as a conductive wire welding material. In the gas welding and tungsten gas protection arc welding, the wire used as a filler metal; in submerged arc welding, electroslag welding and other melting gas protection arc welding, the welding wire is both filled with metal, but also conductive electrodes. The surface of the wire is not coated with an oxidative flux.

- Q:PCB is used to do the PCB, but the middle of the PP material is dicyandiamide, black

- Refers to the surface is FR4 light green, the middle of the black plate

- Q:How to degrease the wood

- Catalytic polymerization Under certain conditions, α and β - pinene will produce polymerization, the formation of yellow sticky material, so that it is fixed or associated with wood, such as aluminum chloride, heme, bleach, tested proved to be effective But the most commonly used boron trifluoride, the boron trifluoride alcohol solution applied to the surface of the plate, it will change the composition of the resin in the terpene, α and β - pinene can be converted into less volatile or Non-volatile, sticky, non-flowable fractions. Brush the boron trifluoride solution at a concentration of 26% on the surface of the resin to reduce the effect of resin bleed [1]. But this method only Wood surface treatment, the wood within the terpene does not change, will still move to the surface of the resin and produce seepage, so this method is suitable for dry after the low moisture content of wood, in the wood before finishing.

- Q:Plate fire rating, such as glass magnesium board incombustibility to A1 level, how to distinguish these, how many fire rating?

- If it is a real glass magnesium board can reach a level, because he can use the material to make him a level

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EASY-CLEANING PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords