PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

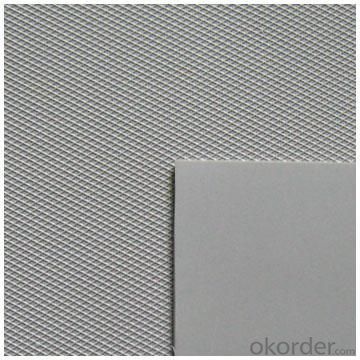

PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness

Product Description of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

Images of PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Does a waterproofing membrane provide any insulation against temperature fluctuations?

- Insulation against temperature fluctuations is not provided by a waterproofing membrane. The main purpose of a waterproofing membrane is to hinder the infiltration of water or moisture into the safeguarded region. It functions as a shield to maintain the structure's dryness and safeguard it from potential water harm. Although it might provide a certain level of thermal resistance based on its thickness and material characteristics, it is not crafted or intended to furnish insulation against temperature fluctuations. In construction, materials such as insulation foam or insulation boards are commonly employed to offer insulation.

- Q: Does a waterproofing membrane require any special considerations for installation in earthquake-prone areas?

- Yes, a waterproofing membrane does require special considerations for installation in earthquake-prone areas. In these areas, the ground is more susceptible to movement and shaking, which can significantly impact the integrity of the waterproofing system. Therefore, it becomes crucial to take additional precautions to ensure that the membrane is properly installed and capable of withstanding seismic activity. One important consideration is the selection of the waterproofing membrane itself. It is recommended to choose a membrane that has been specifically designed and tested to withstand seismic activity. These membranes are usually more flexible and have higher tensile strength to accommodate ground movement during earthquakes. Additionally, the installation process should be executed with utmost care and attention to detail. The membrane should be properly anchored or secured to the substrate using appropriate fasteners and adhesives. Reinforcement techniques such as the use of reinforcing fabric or mesh can also be employed to enhance the membrane's resistance to movement. Furthermore, it is essential to ensure that all seams and joints in the membrane are properly sealed and reinforced. Special attention should be given to areas that are more prone to movement, such as corners, edges, and penetrations. Using compatible and high-quality sealants or adhesives will help maintain the integrity of these vulnerable points. Regular inspections and maintenance are also crucial in earthquake-prone areas. Inspecting the membrane periodically for any signs of damage, such as cracks or separations, allows for early detection and timely repairs. Additionally, it is vital to have a contingency plan in place to address any potential damage that may occur during an earthquake, including emergency repair procedures. In summary, installing a waterproofing membrane in earthquake-prone areas requires careful consideration and adherence to specific guidelines. By selecting an appropriate membrane, properly anchoring and reinforcing it, ensuring proper sealing of seams and joints, and conducting regular inspections, the waterproofing system can be better prepared to withstand earthquakes and provide long-lasting protection against water intrusion.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Yes, a waterproofing membrane can definitely be used for stadiums or arenas. In fact, it is highly recommended to use waterproofing membranes in these large-scale structures to protect them from water damage and leaks. Stadiums and arenas are often exposed to various weather conditions, including heavy rain and snow, which can potentially cause water infiltration into the structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the building envelope and causing damage to the structural components, such as concrete or steel. It helps to maintain the integrity of the structure and prolong its lifespan. Additionally, waterproofing membranes can also provide protection against other forms of moisture, such as condensation and humidity, which can lead to mold growth and deterioration of materials. Therefore, using a waterproofing membrane is a crucial step in ensuring the durability and longevity of stadiums and arenas.

- Q: Can a waterproofing membrane be used in coastal areas?

- Indeed, the utilization of a waterproofing membrane is viable in coastal regions. Given their susceptibility to copious amounts of moisture and water exposure, it becomes imperative to implement efficient waterproofing measures. By appropriately installing and upkeeping a waterproofing membrane, one can establish a protective barrier, effectively thwarting water infiltration and averting structural damage while ensuring their longevity. Nevertheless, it is crucial to opt for a membrane specifically tailored for coastal environments as they exhibit heightened resistance to saltwater and possess superior durability to withstand the harsh coastal conditions. Moreover, routine inspection and maintenance are imperative to guarantee the continued efficacy of the waterproofing membrane in coastal areas.

- Q: Can a waterproofing membrane be used in saunas?

- Indeed, a sauna can utilize a waterproofing membrane. Given that saunas consist of environments abundant in moisture, implementing a waterproofing membrane can effectively avert water damage and shield the underlying structure against moisture infiltration. The membrane functions as a barrier, effectively impeding the permeation of water and mitigating potential complications like mold growth, mildew formation, and rot. The selection of a waterproofing membrane specifically engineered for high-moisture regions, capable of withstanding the intense heat and humidity characteristic of saunas, is of utmost importance. Additionally, proper installation and adherence to manufacturer guidelines are essential to guarantee the efficiency and durability of the waterproofing membrane within a sauna setting.

- Q: Can a waterproofing membrane be used in coastal areas?

- Yes, a waterproofing membrane can be used in coastal areas. These membranes are specifically designed to withstand harsh weather conditions, including exposure to saltwater, high humidity, and extreme temperatures. They provide an effective barrier against water penetration and can protect structures from the damaging effects of coastal environments.

- Q: Can a waterproofing membrane be applied on top of insulation materials?

- Yes, a waterproofing membrane can be applied on top of insulation materials. In fact, it is often recommended to install a waterproofing membrane over insulation materials to provide an added layer of protection against moisture infiltration. This is especially important in areas where water damage is a concern, such as basements or areas prone to heavy rainfall. The waterproofing membrane helps to prevent water from seeping into the insulation and causing damage or reducing its effectiveness. Additionally, the membrane acts as a barrier, preventing water vapor from penetrating the insulation and potentially leading to condensation or mold growth. However, it is important to ensure that the insulation materials are properly installed and that any necessary air gaps or drainage systems are in place to prevent water from becoming trapped between the membrane and the insulation.

- Q: Can a waterproofing membrane be used for plaza decks?

- Plaza decks necessitate safeguarding against water infiltration to avoid harm to the underlying structure. This is where the application of a waterproofing membrane comes into play. These membranes are specifically designed to create a barrier, preventing water from permeating the deck and causing issues like leaks, deterioration, and structural damage. Typically composed of materials such as bitumen, rubber, or polyurethane, these membranes boast high resistance against water penetration. By incorporating a waterproofing membrane onto a plaza deck, it ensures the deck remains impervious to water, thereby preserving the integrity of the entire structure. Furthermore, these membranes offer additional advantages such as UV resistance, durability, and easy maintenance, rendering them an ideal solution for plaza decks.

- Q: Can a waterproofing membrane be used for a plaza deck?

- Indeed, a plaza deck can utilize a waterproofing membrane. A plaza deck, typically raised and subject to diverse weather conditions like rain, snow, and sunlight, necessitates the use of waterproofing membranes. These membranes are specifically designed to act as a shield against water intrusion and safeguard the underlying structure against moisture-related harm. They are commonly employed in outdoor settings, including plaza decks, with the aim of averting water seepage into the building or structure below. The installation of a waterproofing membrane on a plaza deck not only guarantees the deck's endurance and resilience but also offers pedestrians a secure and dry environment.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- Yes, a waterproofing membrane can be used in conjunction with expansion joint systems. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from moisture damage. Expansion joint systems, on the other hand, are installed to allow for movement and accommodate thermal expansion and contraction in structures. By combining the use of a waterproofing membrane and expansion joint systems, it is possible to provide both waterproofing and movement accommodation in a structure. This ensures that the structure remains protected from water damage while allowing for necessary movement. It is important to properly design and install both the waterproofing membrane and the expansion joint system to ensure their compatibility and effectiveness.

Send your message to us

PVC Fiberglass Reinforced Waterproof Membrane with 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords