PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness

Product Description of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

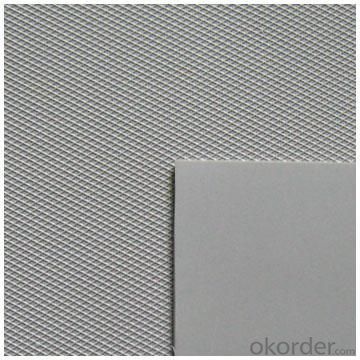

Images of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on plastic surfaces?

- Yes, a waterproofing membrane can be used on plastic surfaces.

- Q: Can waterproofing membranes be used on concrete pools?

- Indeed, concrete pools can benefit from the utilization of waterproofing membranes. These membranes are purposely engineered to serve as a defense against water infiltration and can be administered on a multitude of surfaces, including concrete. Over time, concrete pools are prone to water seepage as a result of cracks or degradation. By applying a waterproofing membrane, the occurrence of such predicaments can be mitigated. Typically, the membrane is administered to the inner surface of the pool, thereby establishing a seamless and impervious seal. It is imperative to select a top-notch waterproofing membrane that is specifically formulated for swimming pool use to guarantee enduring and efficacious outcomes.

- Q: Are there any specific installation requirements for waterproofing membranes?

- Waterproofing membranes have specific installation requirements that vary depending on the type of membrane. However, there are some general guidelines that apply to most installations. To begin, it is crucial to adequately prepare the surface where the membrane will be applied. This involves cleaning the surface, removing any loose debris or previous coatings, and ensuring it is smooth and free from irregularities. Proper surface preparation allows for better adhesion between the membrane and the surface. Following that, the membrane should be applied in accordance with the manufacturer's instructions. This typically involves using a suitable adhesive or bonding agent to attach the membrane to the surface. It is important to adhere to the recommended application rate and ensure a uniform application without air bubbles or wrinkles. In addition to correct application, special attention should be given to the seams and joints of the membrane. These areas are particularly vulnerable to water penetration, so they need to be carefully sealed using an appropriate sealant or tape. This guarantees a watertight seal and prevents any water from seeping through the seams. Lastly, it is essential to safeguard the installed membrane from damage during and after installation. This can be achieved by covering the membrane with a protective layer, such as geotextile fabric or a layer of soil, to prevent punctures or tears. Additionally, any construction or landscaping work following the installation should be done cautiously to avoid harming the membrane. Ultimately, the specific installation requirements for waterproofing membranes depend on the type of membrane and the project's specific conditions. It is always advisable to consult the manufacturer's instructions and guidelines to ensure proper installation and long-lasting waterproofing performance.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Yes, a waterproofing membrane can be used on sloped roofs. Waterproofing membranes are designed to provide a protective barrier against water penetration, and their flexibility allows them to conform to the shape of sloped roofs effectively. This helps prevent water from seeping into the structure and causing damage.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Residential buildings or homes can indeed benefit from the use of a waterproofing membrane. Construction commonly relies on waterproofing membranes to safeguard against water infiltration, shielding both the structure and interior from moisture-induced harm. These versatile membranes find application in diverse areas like basements, roofs, foundations, and bathrooms, among others. By effectively blocking water, these membranes effectively thwart leaks, mold proliferation, and deterioration of building materials. Consequently, employing a waterproofing membrane proves highly efficacious in safeguarding the longevity and durability of residential buildings or homes.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Yes, a waterproofing membrane can be used on tunnels with fire protection systems. The waterproofing membrane is designed to provide protection against water ingress, while the fire protection system is designed to prevent or minimize the spread of fire. These two systems can be installed and utilized together to ensure the safety and integrity of the tunnel infrastructure.

- Q: Can a waterproofing membrane be used for swimming pool decks and patios?

- Yes, a waterproofing membrane can be used for swimming pool decks and patios. A waterproofing membrane is designed to prevent water penetration and protect the underlying structure from water damage. Swimming pool decks and patios are constantly exposed to water, whether through splashing or rain, making them susceptible to water damage. By applying a waterproofing membrane, you can ensure that the pool deck or patio remains protected and free from water-related issues such as cracking, mold, or deterioration. This membrane acts as a barrier, preventing water from seeping into the concrete or other materials, thus extending the lifespan of the pool deck or patio. It is essential to choose a high-quality and suitable waterproofing membrane specifically designed for outdoor use to ensure optimal performance and durability.

- Q: Can a waterproofing membrane be used in conjunction with solar panel installations?

- Yes, a waterproofing membrane can be used in conjunction with solar panel installations. Waterproofing membranes are commonly used to protect roofs and other surfaces from water damage, and they can provide an additional layer of protection for solar panels. This can help to prevent water infiltration and potential damage to the solar panels and their electrical components. Additionally, waterproofing membranes can also help to extend the lifespan of the solar panel system by providing an extra barrier against moisture and other environmental factors.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. Plant rooms and mechanical spaces are areas where equipment, machinery, or systems are installed, and they often contain pipes, tanks, or other components that require protection from water damage. A waterproofing membrane is a durable, flexible, and watertight barrier that can be applied to surfaces such as walls, floors, or ceilings to prevent water infiltration. By using a waterproofing membrane in plant rooms or mechanical spaces, you can ensure the longevity and functionality of the equipment and systems by protecting them from water leaks or moisture damage. Additionally, a waterproofing membrane can also provide a vapor barrier, preventing the buildup of condensation or humidity, which can be detrimental to sensitive equipment.

- Q: Is a waterproofing membrane compatible with different types of roofing materials?

- Indeed, various roofing materials are compatible with a waterproofing membrane. This flexible solution offers versatility, making it suitable for asphalt shingles, metal roofs, concrete roofs, and even flat roofs. Its purpose is to create a barrier against water infiltration, regardless of the roofing material used. It can be directly applied to the roof's surface or used as an underlayment prior to installing the roofing material. This compatibility guarantees the effective use of the waterproofing membrane, safeguarding and prolonging the lifespan of diverse roof types.

Send your message to us

PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords