Fiberglass Insulation Sleeve - PVC Fiberglass Insulation Sleeving 4KV

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 5000000METER/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of PVC Fiberglass Insulation Sleeving 4 KV:

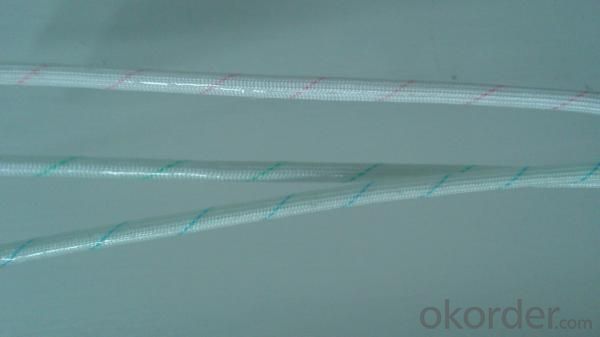

Diameter:0.5mm~30mm

Breakdown Voltage:4KV,

Colour: red line, green line, blue line and all kinds of color

Applications of PVC Fiberglass Insulation Sleeving of 4 KV

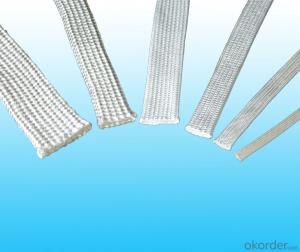

1.Silicone coated or PVC coated

2.Good self-extinguish

3.Good dielectric features

Heat-resistance: A class 105°C

Diameter: 0.5mm---40mm

Breakdown voltage: 1.5KV, 2.5KV, 4KV, 7KV

temperature range: -25 C ~ 130C;

Colour: red line, green line, blue line and all kinds of color

Material : Non-alkali fiberglass braided sleeving with coating Polyvinyl chloride resin

Property: With excellent softness and elasticity, high dielectric and chemical property .

Application:PVC fiberglass sleeving is fiberglass sleeving coated with PVC resin, with very good flexibility and dielectric features, it is

widely used as insulating and protection material for motor and electric appliance

Packaging & Delivery of PVC Fiberglass Insulation Sleeving 4 KV

Production Line of PVC Fiberglass Insulation Sleeving 4KV

- Q: What are the manufacturers of high temperature sleeving (fiberglass, silicone sleeve)?

- Outside the fiber silica glass fiber casing (MBQGJ) is composed of glass fiber woven by alkali silica gel coating, high temperature drying and shaping. The product has heat resistance, corrosion resistance, anti aging characteristics, softness, and can play the role of insulation.

- Q: What are fiberglass tubes, and what are they mainly used for?

- Motor winding joints, electric mattress, rice meal fort, electric iron, general electric heating equipment, almost all used.

- Q: How about the 35 thousand volt transformer glass fiber reinforced plastic bushing?

- Visual inspection. Large current transformer casing mechanical strength, the production method of the invention patent technology of high insulation dielectric loss less stable, leading to similar products, and stable operation, limit margin test proved that this product is no fire and explosion danger.

- Q: What's the meaning of GRP cable sheath ncbb100x5?

- NCBB means glass fiber reinforced plastic cable protection tube, also a kind of GRP sheath. 100 * 5 means diameter 100mm, and 5 sides are placed side by side.

- Q: Silicone resin glass fiber casing factory self extinguishing tube which is better?

- Outside the fiber silica glass fiber casing (MBQGJ) is composed of glass fiber woven by alkali silica gel coating, high temperature drying and shaping. The product has heat resistance, corrosion resistance, anti aging characteristics, softness, and can play the role of insulation.Products are mainly used in high temperature, high voltage environment, mainly transformers, engines, generators, electric heating equipment

- Q: Insulated electrical sleeves will melt at high temperature

- As long as the temperature reaches the melting temperature of the casing material, it will melt. Iron can be turned into liquid. Can polymer plastics not melt? It's just how much this "high temperature" means.

- Q: Silicone rubber sleeving can withstand high temperatures?

- Silicone rubber fiberglass sleeve: silicone rubber fiberglass sleeve (English Name: Silicone rubber fiberglass sleeving), also known as fire resistant casing, casing, high purity glass fiber tube made of alkali free, then in the outer wall of the tube coated by silicone vulcanization process and. After vulcanization, it can be used for a long time in the temperature range of -65 degrees C - 260 degrees C and maintain its soft and elastic properties.

- Q: What are the specifications of PVC threading pipes?

- Metal tube, ordinary carbon steel wire casing (wire tube), metal flexible pipe (galvanized pipe, stainless steel pipe, plastic coated metal snakeskin snakeskin tube)

- Q: The use of soft glass fiber insulation casing line please do

- Polypropylene is acrylic, polyester is polyester. It's not good to make quilts! If you must choose chemical fiber, hollow cotton to the good;

- Q: What is the difference between a ceramic fiber shell and an aluminum silicate tube shell?

- Ceramic fiber shell and aluminum silicate tube shell is actually the same kind of thing, just name different. Belong to the family of Portland, ceramic fiber tube and shell is a professional name, aluminum silicate segment is referred to as.

1. Manufacturer Overview

| Location | Jiansu,China |

| Year Established | 1956 |

| Annual Output Value | |

| Main Markets | Europe, Americans, Middle East, South East Asia |

| Company Certifications | ISO9001:2008;ISO14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Insulation Sleeve - PVC Fiberglass Insulation Sleeving 4KV

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 5000000METER/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords