Fiberglass Insulation Sleeve 1.5kV PVC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 METER m

- Supply Capability:

- 5000000METER/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

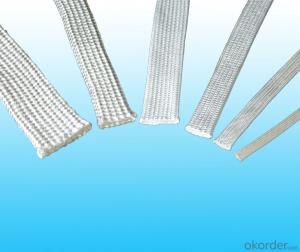

Product Description of PVC Fiberglass Insulation Sleeving 1.5KV:

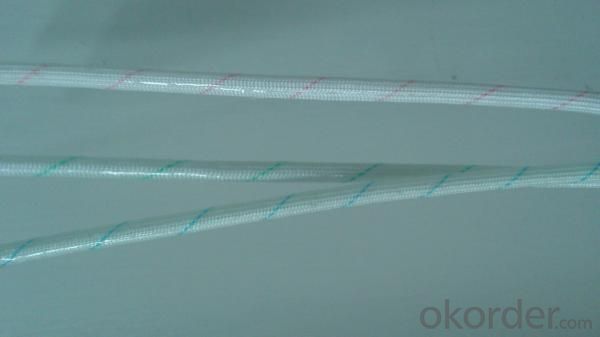

Diameter:0.5mm~30mm

Breakdown Voltage:1.5KV,

Colour: red line, green line, blue line and all kinds of color

Applications of PVC Fiberglass Insulation Sleeving of 1.5KV

1.Silicone coated or PVC coated

2.Good self-extinguish

3.Good dielectric features

Heat-resistance: A class 105°C

Diameter: 0.5mm---40mm

Breakdown voltage: 1.5KV, 2.5KV, 4KV, 7KV

temperature range: -25 C ~ 130C;

Colour: red line, green line, blue line and all kinds of color

Material : Non-alkali fiberglass braided sleeving with coating Polyvinyl chloride resin

Property: With excellent softness and elasticity, high dielectric and chemical property .

Application:PVC fiberglass sleeving is fiberglass sleeving coated with PVC resin, with very good flexibility and dielectric features, it is

widely used as insulating and protection material for motor and electric appliance

Packaging & Delivery of PVC Fiberglass Insulation Sleeving 1.5KV

Production Line of PVC Fiberglass Insulation Sleeving 1.5KV:

- Q: What are the manufacturers of high temperature sleeving (fiberglass, silicone sleeve)?

- Within the plastic fiber glass fiber casing MBQGX is made of silicone rubber with high temperature process so that it is completely curing stereotypes, and the alkali free glass fiber woven coated, then coated with special varnish dip, the temperature of drying and forming made. The product has the characteristics of heat resistance, corrosion resistance, aging resistance, softness and so on. It also plays a good insulation and high pressure resistance.

- Q: What's the yellow tube?

- Is often used in home decoration, concrete catgut embedding protection, general sale of electrical materials are sold, and cheap.Of course the insulation is satisfactory, but it is almost impossible to pull out the line without damage, and the grooves on the concrete are rather laborious and may damage the structure. The pros and cons of this waste should present put fine timber to petty use from the lack of coordination of architectural design.

- Q: Characteristics and application of fire protection sleeve of fire protection sleeve

- Superior resistance to high temperatureThe silicone structure on the surface of the fireproof casing contains both organic and inorganic structures. This particular composition and molecular structure make it characteristic of organic compounds and inorganic compounds. Compared with other polymer materials, the most prominent is its high temperature resistance. The silicon oxygen bond (SiO) as the main chain structure, C-C bond is 82 thousand and 600 kcal / mole, SiO bond card / 121 thousand in silicon molar, so its high thermal stability, high temperature (or radiation) molecular bond doesn't break, do not break down. Silicone is not only resistant to high temperature and low temperature resistance, can be used in a wide temperature range. Both chemical properties and physical and mechanical properties vary little with temperature.

- Q: Insulated electrical sleeves will melt at high temperature

- Insulated electrical sleeves are divided into several materials, such as fiberglass insulated sleeves, PVC bushings, heat shrinkable sleeves, etc.. The temperature characteristics are different, such as the applicable temperature range of the heat shrinkable sleeve: -55 DEG C to 125 DEG C.

- Q: What's the use of a wax pipe in an electrician?

- Insulation, yellow wax tube is generally used in equipment, need to strengthen the insulation place, as well as the role of flame retardant, prevention and control of electric wire leakage due to high temperature

- Q: What are the transformer bushings?

- Oil immersed transformer bushings are generally ceramic, in order to stability of the ceramic bar. I said the plastic, it is estimated that you say BMC, SMC, DMC resin bar! These new things are generally seen in some dry-type transformers, bushings (insulators), busbars, insulators and general switches, bushings, and some through wall bushings. Oil immersed transformers are estimated to be afraid of their physical and chemical changes during long periods of oil immersion.

- Q: Can fiber insulated pipe wires be buried in cement walls?

- Fiber insulated sleeves is yellow wax tubes, if it is a yellow wax tube wire, is buried in the wall, but the electrical construction specification is the use of yellow wax tube is not allowed, because after the use of the yellow wax tubes if the wire problems, there is no way to update the electric line.

- Q: What is the difference between a ceramic fiber shell and an aluminum silicate tube shell?

- Ceramic fiber shell and aluminum silicate tube shell is actually the same kind of thing, just name different. Belong to the family of Portland, ceramic fiber tube and shell is a professional name, aluminum silicate segment is referred to as.

- Q: What is a high temperature resistant insulated fire protection sleeve?

- High temperature insulation fire protection casing is designed for iron and steel, automobile, shipbuilding, aerospace, metallurgy, machinery, petrochemical, chemical, military, national defense, scientific research and other industries supply quality and safety special (coating) high temperature fireproof casing. Applicable to steel, smelting, shipbuilding, aerospace, aviation, military and other industries such as chemical industry high temperature area, heating area of cable, cable, tubing, fluid pipe mill, cutting edge cable, generators, electric voltage equipment, large-scale construction, hydraulic system, automotive wiring harness and exhaust pipe etc.. In the high temperature of 560 DEG C environment to provide long-term, reliable insulation protection, anti radiation, anti heat resistance, short than or equal to 1700 DEG C high temperature molten steel or heat shock of liquid.

- Q: Why should transformer coils be graded insulated?

- According to use can be divided into: power transformers and special transformers (electric furnace transformer, rectifier transformer, power frequency test transformer, voltage regulator, mine, variable audio transformers, intermediate frequency transformers, high frequency transformer, transformer, instrument transformer, the impact of electronic transformer, reactor, transformer etc.). Circuit symbols are often used as the beginning of numbers. Examples: T01, T201, T, etc..

1. Manufacturer Overview

| Location | Jiansu,China |

| Year Established | 1956 |

| Annual Output Value | |

| Main Markets | Europe, Americans, Middle East, South East Asia |

| Company Certifications | ISO9001:2008;ISO14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Insulation Sleeve 1.5kV PVC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 METER m

- Supply Capability:

- 5000000METER/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords