PUMPING CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

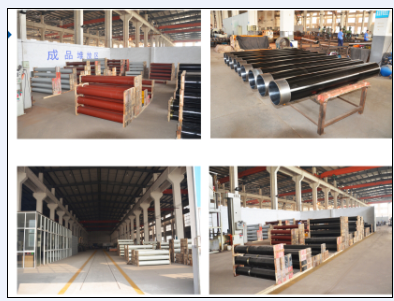

Product Description:

The Concrete Pump Delivery Cylinder normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder is a concrete pumping for combined use with other concrete pumps in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN200*2162

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: SANY

5. Material: C45

6. Quenching and tempering to improve the hardness to HB241-280

7. Inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

Product Advantages:

OKorder's Cylinders Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders according to customers request?

A4: Yes, we can produce Cylinders according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

Concrete Cylinder | ||

Material | High Manganese Steel | |

Special | Coating hardness layer in the internalwall | |

Application | In concrete pump trucks | |

For Brand | Sany,Putzmeister,Schwing,,Zoomlion,CIFA etc | |

Details information | ||

Brand | Model | |

219 - DN180*1775-1600 | ||

Schwing | BP3000 | 219 - DN200*1775-1600 |

254 - DN230*2125-1800 | ||

DN230*2300mm | ||

DN230*2100mm | ||

Putzmeister | DN230*1600mm | |

DN200*1600mm | ||

DN180*2000mm | ||

40C1410 | 206-DN180*1530-1400 | |

50C1410 | 210- DN180*1545-1400 | |

60A1406 | 219- DN195*1570-1400 | |

Sany | 60C1416 | 226- DN195*1570-1400 |

60C1816 | 232- DN200*1946-1800 | |

C120/37A | 232- DN200*2162-2000 | |

C120/48 | 262- DN230*2146-2000 | |

62EA | 203-DN 180*1605-1400 | |

62G | 219-DN200*1187-1000 | |

62D | 219-DN200*1587-1400 | |

Zoomlion | 62H | 219-DN200*1787-1600 |

62CA | 219-DN200*1862-1600 | |

62M | 219-DN200*2022-1800 | |

0019931A | 219-DN200*2022-1800 | |

62L | 245-DN205*2284-2000 | |

- Q: Are there any specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts. These guidelines ensure proper installation techniques are followed to ensure the assemblies are securely and correctly installed. It is important to consult the manufacturer's instructions and adhere to industry standards to ensure optimal performance and safety of the concrete pump spare parts.

- Q: What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

- Q: How often should concrete pump gearboxes be inspected and maintained?

- Concrete pump gearboxes should be inspected and maintained regularly to ensure their optimal performance and longevity. The frequency of inspections and maintenance depends on several factors such as the usage of the concrete pump, the working environment, and the manufacturer's recommendations. In general, it is recommended to have a thorough inspection and maintenance at least once a year. However, if the concrete pump is used extensively or operated in harsh conditions, more frequent inspections may be necessary. This can be done every six months or even quarterly. Regular maintenance should include checking for any signs of wear and tear, lubricating gears and bearings, and replacing any worn-out or damaged parts. It is important to follow the manufacturer's guidelines and consult with a professional if there are any concerns or specific requirements for the concrete pump gearbox. By conducting regular inspections and maintenance, potential issues can be identified early on and addressed promptly, ensuring the smooth and efficient operation of the concrete pump gearboxes.

- Q: What are the different types of concrete pump hydraulic pumps?

- Concrete pumps commonly utilize a variety of hydraulic pumps. Here are several types: 1. Gear pumps, which are widely employed in concrete pumps, consist of meshing gears that propel hydraulic fluid from the inlet to the outlet. Gear pumps are renowned for their simplicity, durability, and reliability. 2. Piston pumps, another popular choice in concrete pumps, employ reciprocating pistons to move hydraulic fluid. These pumps are known for their ability to handle heavy-duty applications and generate high pressure. 3. Vane pumps are often used in smaller concrete pumps or as auxiliary pumps in larger ones. They rely on rotating vanes within a housing to move the hydraulic fluid. Vane pumps are prized for their compact size and efficiency. 4. High-pressure concrete pumps commonly employ radial piston pumps. These pumps have multiple pistons arranged radially around a central shaft. The pistons' alternating motion creates the pumping action. Radial piston pumps are esteemed for their power and efficiency. 5. Large concrete pumps frequently utilize axial piston pumps. These pumps feature multiple pistons arranged in a circular pattern around a central shaft. The pistons move linearly to generate the pumping action. Axial piston pumps excel in high flow rates and pressure capabilities. Ultimately, the choice of hydraulic pump for a concrete pump depends on factors such as pump size, desired pressure and flow rate, and specific application requirements.

- Q: How can a faulty concrete pump S valve affect the concrete flow?

- A faulty concrete pump S valve can affect the concrete flow by causing disruptions, blockages, or uneven distribution of the concrete. The S valve is responsible for controlling the direction of the concrete flow, and when it malfunctions, it can lead to decreased or inconsistent flow rates. This can result in delays in the construction process, poor concrete quality, or even damage to the pump system.

- Q: How can a malfunctioning control box affect the pump's operation?

- The operation of a pump can be negatively affected by a control box that malfunctions. Initially, it can lead to an imprecise or inconsistent control of the pump's functions. This implies that the pump may not initiate or halt at the desired moments or operate at the correct velocity, resulting in ineffective or insufficient pumping. Furthermore, a control box that malfunctions can cause electrical problems, resulting in power fluctuations or even power surges. These electrical complications can harm the pump's motor or other components, leading to premature deterioration or complete malfunction. Moreover, a malfunctioning control box can also disrupt the communication between the pump and other systems. This can impact the pump's capacity to receive or transmit signals, resulting in a lack of synchronization with other equipment or systems that depend on the pump's operation. This lack of synchronization can result in system failures or interruptions in the overall process or operation that the pump supports. In conclusion, a malfunctioning control box can have adverse effects on the operation of a pump including imprecise control, electrical problems, and disruption of communication with other systems. It is essential to regularly inspect and maintain control boxes to prevent these malfunctions and ensure the reliable and efficient operation of pumps.

- Q: How long does a concrete pump piston typically last?

- A concrete pump piston typically lasts between 20,000 to 60,000 pumping hours, depending on factors such as maintenance, usage, and the quality of the pump.

- Q: How often should concrete pump control levers be inspected and replaced?

- Concrete pump control levers should be inspected regularly, ideally on a monthly basis, to ensure they are in proper working condition. However, the need for replacement would depend on various factors such as the quality of the lever, frequency of use, and any signs of wear or damage. If any issues or concerns arise during inspection, prompt replacement should be considered to maintain safe and efficient operation of the concrete pump.

- Q: What do these types of concrete pumps mean?

- After the 16 is the motor power kW (landlord 16 seems to have a mistake, usually 110) or the manufacturer's serial number.

- Q: What are the different types of concrete pump clamps?

- There are several different types of concrete pump clamps, including snap clamps, bolt clamps, wedge clamps, and quick release clamps. These clamps are used to secure pipes and hoses in place and ensure a tight and secure connection during concrete pumping operations.

Send your message to us

PUMPING CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords