PUMPING CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

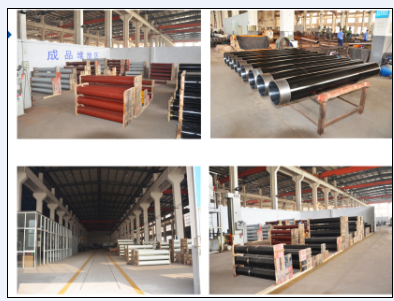

The Concrete Pump Delivery Cylinder DN180*1545 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN180*1545 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN180*1545 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN180*1545

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN180*1545 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN180*1545 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN180*1545?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN180*1545 according to customers request?

A4: Yes, we can produce Cylinders DN180*1545 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: Are there any specific brands or manufacturers that are recommended for concrete pump spare parts?

- Concrete pump spare parts are highly recommended from various reputable brands and manufacturers. Putzmeister, Schwing, Sany, and Zoomlion are among the top brands in the industry that offer high-quality, reliable, and durable products. Their extensive range of spare parts caters to different models of concrete pumps, ensuring customers can easily obtain the specific parts they require. Moreover, these brands have established a strong market presence and possess a wide network of dealers and distributors worldwide, facilitating convenient access to their spare parts. To ensure the longevity and optimal performance of your concrete pump, it is always advisable to select spare parts from renowned brands and manufacturers.

- Q: How often should concrete pump pistons be inspected and replaced?

- To ensure optimal performance and prevent malfunctions, it is necessary to regularly inspect and replace concrete pump pistons. The frequency of these inspections and replacements depends on various factors, such as the type and volume of concrete being pumped, as well as the operating conditions of the pump. As a general rule, it is recommended to inspect and replace concrete pump pistons every 500 to 1,000 hours of operation. However, this can vary based on the specific recommendations of the pump manufacturer, the quality of the concrete being pumped, and the maintenance and cleaning practices followed. Regular inspections should be conducted to identify any signs of wear, damage, or deterioration in the pistons. This includes examining the rubber seals, valve plates, and other components that may impact the piston's performance. If any cracks, tears, or excessive wear are detected, immediate replacement is necessary to prevent issues like concrete leakage or pressure loss. In addition to regular inspections, it is essential to follow a preventive maintenance schedule that includes routine cleaning and lubrication of the pistons. This will help extend their lifespan and ensure smooth operation. It is important to note that the recommended intervals for inspection and replacement may vary among different pump manufacturers. Therefore, it is advisable to consult the pump's operation and maintenance manual or seek guidance from the manufacturer or a qualified technician to determine the ideal frequency for inspecting and replacing concrete pump pistons.

- Q: Can I get spare parts for concrete pump hydraulic cylinders and valves?

- Absolutely, spare parts for concrete pump hydraulic cylinders and valves are readily available. There is a wide range of companies and suppliers dedicated to supplying spare parts specifically for construction machinery, such as hydraulic cylinders and valves for concrete pumps. These spare parts can be conveniently obtained online or through nearby distributors. To ensure compatibility and proper operation of the spare parts, it is crucial to provide precise details about the make and model of your concrete pump. Furthermore, it is recommended to select reputable suppliers who offer authentic, top-notch spare parts for optimal performance and longevity.

- Q: What are the signs of a clogged or damaged hydraulic filter?

- A clogged or damaged hydraulic filter may be indicated by several signs. One of the most common signs is a decrease in hydraulic system performance. If you observe a decrease in the speed or power of your hydraulic equipment, it may be due to a clogged filter that restricts the flow of hydraulic fluid. Another sign is an increase in heat within the hydraulic system. As the system struggles to maintain proper fluid flow and pressure, a clogged or damaged filter can cause it to overheat. Furthermore, unusual noises may be noticed coming from the hydraulic system. A clogged filter can result in air becoming trapped in the system, leading to strange noises like whining or grinding. Moreover, the presence of dirty or discolored hydraulic fluid could suggest a clogged or damaged filter. The filter's purpose is to remove dirt and contaminants from the fluid, so if it fails to do so effectively, the fluid will become dirty and discolored. Finally, frequent or recurring issues with the hydraulic system could be an indication of a clogged or damaged filter. The filter plays a critical role in maintaining the overall health of the hydraulic system, so if it is not functioning properly, it can lead to other problems such as pump failure or valve blockages. Regular inspection and replacement of hydraulic filters are crucial to ensure the proper functioning and longevity of your hydraulic system.

- Q: How long does it take to receive concrete pump spare parts after ordering?

- The time it takes to receive concrete pump spare parts after ordering can vary depending on several factors. It is important to note that the availability of the specific spare parts you need and the location of the supplier can significantly impact the delivery time. In general, if the spare parts are readily available and in stock, you can expect to receive them within a few days to a week. This assumes that the supplier has a streamlined order processing system and prompt shipping arrangements. However, if the spare parts are not in stock, it may take longer to receive them. In such cases, the supplier may need to order the parts from a manufacturer or source them from a distributor. This could add additional lead time to the delivery process, ranging from a few weeks to several months, depending on the availability and sourcing process. It is advisable to check with the supplier or manufacturer before placing the order to get an estimate of the delivery time. Factors like the supplier's location, transportation mode, and any potential customs or logistics delays should also be taken into consideration. To expedite the delivery process, some suppliers may offer expedited shipping options at an additional cost. This can be beneficial if you need the spare parts urgently. Overall, the time it takes to receive concrete pump spare parts after ordering can vary, but being proactive, communicating with the supplier, and planning ahead can help ensure a smoother and quicker delivery process.

- Q: How often should a hopper filter be cleaned or replaced?

- The frequency at which a hopper filter should be cleaned or replaced depends on various factors such as the type of hopper, the nature of contaminants, and the usage pattern. As a general guideline, it is recommended to clean or replace the hopper filter at least once every three to six months. However, if the hopper is used in a particularly dusty or dirty environment, or if it handles materials that produce a high level of debris, more frequent cleaning or replacement may be necessary. Regular inspection of the hopper filter is crucial to determine the accumulation of particles and the effectiveness of filtration. Additionally, if the hopper filter starts to show signs of damage or wear, it should be replaced immediately to maintain optimal performance and prevent any potential contamination. Ultimately, it is advisable to refer to the manufacturer's guidelines and recommendations for the specific hopper filter being used.

- Q: How does a concrete pump piston work?

- By creating a back-and-forth movement, the concrete pump piston propels the concrete through the pump and into the desired location. The piston is a cylindrical part that fits snugly inside a cylinder and is connected to a rod, which is linked to a hydraulic system. When the hydraulic system is activated, it propels the rod forward, thereby causing the piston to move in the same direction. As the piston advances, it creates a vacuum behind it, which draws the concrete into the cylinder through an inlet valve. Once the piston reaches the end of its forward stroke, the hydraulic system changes its direction, retracting the rod and causing the piston to move backward. Consequently, this action closes the inlet valve and opens an outlet valve, enabling the concrete to be forced out of the cylinder and into the delivery line. The reciprocating motion of the piston, combined with the alternating opening and closing of the inlet and outlet valves, facilitates a continuous flow of concrete through the pump. This process is rapidly repeated, ensuring efficient and consistent pumping of concrete to the desired location.

- Q: How often should concrete pump control levers be inspected and replaced?

- Regular inspections should be conducted on concrete pump control levers to ensure they are in proper working order. The frequency of these inspections and any necessary replacements will depend on various factors, such as usage levels, environmental conditions, and the quality of equipment maintenance. As a general rule, it is recommended to inspect the control levers at least once a year. This inspection should involve a thorough examination of the lever mechanism to check for any signs of wear, damage, or malfunction. It is also advisable to inspect the levers after any major repairs or maintenance to ensure they have been correctly reinstalled and are functioning properly. If any issues are identified during the inspection, it is crucial to address them promptly. Depending on the severity of the problem, repairs or replacements may be required. Minor repairs can often be carried out on-site, while more significant issues may necessitate the assistance of a professional technician. Regular maintenance, including lubrication and cleaning, is important for extending the lifespan of the control levers. Following the manufacturer's maintenance and usage guidelines can also help prevent premature wear and damage. Ultimately, the frequency of inspections and replacements may vary based on specific circumstances. It is advisable to consult the equipment's manual or the manufacturer for precise recommendations regarding the maintenance and replacement of the control levers.

- Q: In general, how much concrete will be transported per hour for the concrete pump and the pump?

- The length of day pump 36-62m, the efficiency has little effect, regular work is generally 30-40 cubic / hour

- Q: What are the indications of an inaccurate concrete pump pressure gauge?

- Some indications of an inaccurate concrete pump pressure gauge may include inconsistent readings, sudden drops or spikes in pressure, or when the gauge fails to return to zero when the pump is turned off.

Send your message to us

PUMPING CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords